What is Global Elevator Compensation Cable Market?

The Global Elevator Compensation Cable Market is a specialized segment within the broader elevator and escalator industry. These cables are essential components in elevator systems, serving as the lifeline that ensures smooth and efficient operation. Compensation cables are primarily used to balance the weight of the elevator car and counterweight, which helps in reducing the energy consumption of the elevator system. They are designed to withstand the constant motion and tension that occurs as the elevator moves up and down the shaft. The market for these cables is driven by the increasing demand for high-rise buildings and the modernization of existing elevator systems. As urbanization continues to rise, especially in developing countries, the need for efficient and reliable elevator systems becomes more critical. This, in turn, fuels the demand for high-quality compensation cables. Manufacturers are focusing on developing cables that are not only durable but also lightweight and flexible to meet the evolving needs of the industry. The market is characterized by a mix of global and regional players, each striving to offer innovative solutions to gain a competitive edge.

Single Core, Multi-core in the Global Elevator Compensation Cable Market:

In the Global Elevator Compensation Cable Market, cables are categorized into single-core and multi-core types, each serving distinct purposes and offering unique advantages. Single-core cables consist of a single conductor, which makes them simpler in design and easier to manufacture. They are typically used in applications where space is limited, and the electrical requirements are minimal. Single-core cables are known for their flexibility and ease of installation, which makes them a popular choice in straightforward elevator systems. However, their simplicity can also be a limitation, as they may not be suitable for more complex systems that require multiple connections or higher power transmission. On the other hand, multi-core cables consist of multiple conductors within a single cable sheath. This design allows them to handle more complex electrical requirements, making them ideal for modern elevator systems that demand higher power and more intricate control mechanisms. Multi-core cables are often used in high-rise buildings where elevators need to travel long distances and require robust electrical support. The multiple conductors within these cables can carry different types of signals, such as power, control, and communication signals, all within a single cable. This not only simplifies the installation process but also reduces the overall space required for cabling, which is a significant advantage in densely packed elevator shafts. The choice between single-core and multi-core cables in the Global Elevator Compensation Cable Market largely depends on the specific requirements of the elevator system. For instance, in a simple residential building with a low-rise elevator, single-core cables might suffice due to their cost-effectiveness and ease of installation. However, in a commercial skyscraper with multiple elevators and complex control systems, multi-core cables would be more appropriate due to their ability to handle higher power loads and multiple signal types. Manufacturers in the market are continuously innovating to improve the performance and efficiency of both single-core and multi-core cables. Advances in materials technology have led to the development of cables that are not only more durable but also lighter and more flexible. This is particularly important in the context of multi-core cables, where the weight and flexibility of the cable can significantly impact the overall efficiency of the elevator system. Additionally, there is a growing emphasis on sustainability, with manufacturers exploring eco-friendly materials and production processes to reduce the environmental impact of cable manufacturing. In conclusion, the Global Elevator Compensation Cable Market is a dynamic and evolving sector, with single-core and multi-core cables playing crucial roles in the development of modern elevator systems. As the demand for taller and more complex buildings continues to rise, the need for advanced cable solutions will only increase. Manufacturers that can offer innovative, efficient, and sustainable cable solutions will be well-positioned to capitalize on the growth opportunities in this market.

Traction Elevator, Hydraulic Elevator, Others in the Global Elevator Compensation Cable Market:

The usage of Global Elevator Compensation Cable Market products varies significantly across different types of elevators, including traction elevators, hydraulic elevators, and others. In traction elevators, compensation cables are crucial for balancing the weight of the elevator car and counterweight. This balance is essential for the efficient operation of the elevator, as it reduces the energy required to move the elevator car. Traction elevators are commonly used in high-rise buildings, where the height and speed of the elevator necessitate robust and reliable compensation cables. These cables must be able to withstand the constant motion and tension that occurs as the elevator moves up and down the shaft, making durability and flexibility key considerations in their design. In hydraulic elevators, compensation cables play a slightly different role. These elevators use a hydraulic ram to move the elevator car, and the compensation cables are used to manage the weight of the car as it moves. While hydraulic elevators are typically used in low to mid-rise buildings, the need for efficient and reliable compensation cables is still critical. The cables help to ensure smooth and stable operation, reducing the strain on the hydraulic system and improving the overall efficiency of the elevator. In this context, the flexibility and lightweight nature of the cables are particularly important, as they need to move easily with the elevator car without adding unnecessary weight or resistance. Beyond traction and hydraulic elevators, compensation cables are also used in a variety of other elevator systems, each with its own unique requirements. For example, in machine-room-less (MRL) elevators, which are becoming increasingly popular due to their space-saving design, compensation cables are essential for maintaining balance and stability. These elevators often require more compact and flexible cable solutions to fit within the limited space available. Similarly, in panoramic elevators, which are designed to provide passengers with a view of the surrounding environment, compensation cables must be carefully integrated into the design to ensure they do not obstruct the view or detract from the aesthetic appeal of the elevator. Overall, the usage of compensation cables in the Global Elevator Compensation Cable Market is diverse and multifaceted, with each type of elevator presenting its own set of challenges and requirements. Manufacturers must be able to offer a range of cable solutions that can meet the specific needs of different elevator systems, from high-rise traction elevators to compact MRL elevators. As the demand for more efficient, reliable, and aesthetically pleasing elevator systems continues to grow, the importance of high-quality compensation cables will only increase.

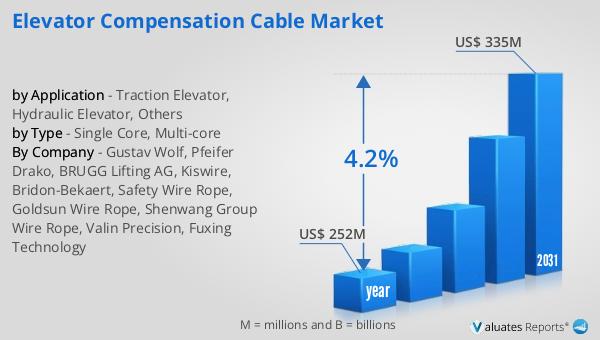

Global Elevator Compensation Cable Market Outlook:

The global market for Elevator Compensation Cable, valued at $252 million in 2024, is on a growth trajectory, with projections indicating it will reach $335 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. This upward trend is driven by several factors, including the increasing demand for high-rise buildings and the modernization of existing elevator systems. As urbanization continues to rise, particularly in developing countries, the need for efficient and reliable elevator systems becomes more critical. This, in turn, fuels the demand for high-quality compensation cables. Manufacturers in the market are focusing on developing cables that are not only durable but also lightweight and flexible to meet the evolving needs of the industry. The market is characterized by a mix of global and regional players, each striving to offer innovative solutions to gain a competitive edge. Advances in materials technology have led to the development of cables that are not only more durable but also lighter and more flexible. This is particularly important in the context of multi-core cables, where the weight and flexibility of the cable can significantly impact the overall efficiency of the elevator system. Additionally, there is a growing emphasis on sustainability, with manufacturers exploring eco-friendly materials and production processes to reduce the environmental impact of cable manufacturing. As the demand for taller and more complex buildings continues to rise, the need for advanced cable solutions will only increase. Manufacturers that can offer innovative, efficient, and sustainable cable solutions will be well-positioned to capitalize on the growth opportunities in this market.

| Report Metric | Details |

| Report Name | Elevator Compensation Cable Market |

| Accounted market size in year | US$ 252 million |

| Forecasted market size in 2031 | US$ 335 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gustav Wolf, Pfeifer Drako, BRUGG Lifting AG, Kiswire, Bridon-Bekaert, Safety Wire Rope, Goldsun Wire Rope, Shenwang Group Wire Rope, Valin Precision, Fuxing Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |