What is Global Robotic Welding Equipment Market?

The Global Robotic Welding Equipment Market is a rapidly evolving sector that plays a crucial role in modern manufacturing processes. This market encompasses a wide range of robotic systems designed to automate the welding process, which is essential for joining materials, typically metals, in various industries. The use of robotic welding equipment offers numerous advantages, such as increased precision, speed, and efficiency, while also reducing labor costs and minimizing human error. These systems are equipped with advanced technologies, including sensors and software, to ensure high-quality welds and adaptability to different welding tasks. As industries continue to seek ways to enhance productivity and maintain competitive edges, the demand for robotic welding equipment is expected to grow. This market is driven by the need for automation in manufacturing, the rising adoption of Industry 4.0 practices, and the increasing complexity of products that require precise and reliable welding solutions. Overall, the Global Robotic Welding Equipment Market is a key component of the broader automation landscape, contributing significantly to the advancement of manufacturing capabilities worldwide.

Arc Welding, Spot Welding, Others in the Global Robotic Welding Equipment Market:

Arc welding, spot welding, and other welding techniques form the backbone of the Global Robotic Welding Equipment Market, each serving distinct purposes and applications. Arc welding is one of the most prevalent methods, known for its versatility and ability to join a wide range of metals. It involves using an electric arc to melt the workpieces and filler material, creating a strong joint upon cooling. Robotic arc welding systems are equipped with advanced sensors and control systems to ensure precision and consistency, making them ideal for industries such as automotive, construction, and shipbuilding. These systems can handle complex geometries and large-scale production, significantly enhancing efficiency and reducing production time. Spot welding, on the other hand, is primarily used for joining sheet metal components, making it a staple in the automotive industry. This technique involves applying pressure and heat to the metal surfaces, creating a weld at specific points. Robotic spot welding systems are designed to perform repetitive tasks with high accuracy, ensuring uniformity and strength in the welds. They are particularly beneficial in mass production environments, where speed and consistency are paramount. Other welding techniques, such as laser welding and resistance welding, also play a significant role in the market. Laser welding, for instance, offers high precision and is suitable for applications requiring minimal heat distortion. It is commonly used in industries like electronics and aerospace, where intricate and delicate components are involved. Resistance welding, which includes techniques like seam welding and projection welding, is known for its efficiency and ability to join thin materials. These methods are often employed in the manufacturing of appliances and electrical components. The integration of robotic systems in these welding processes not only enhances productivity but also ensures safety by minimizing human exposure to hazardous environments. As technology continues to advance, the capabilities of robotic welding systems are expected to expand, offering even greater flexibility and efficiency in various industrial applications.

Industrial, Aerospace, Car, Others in the Global Robotic Welding Equipment Market:

The Global Robotic Welding Equipment Market finds extensive usage across various sectors, including industrial, aerospace, automotive, and others, each benefiting from the unique advantages offered by robotic welding systems. In the industrial sector, robotic welding equipment is widely used to enhance production efficiency and maintain high-quality standards. Industries such as construction, shipbuilding, and heavy machinery rely on these systems to handle large-scale welding tasks with precision and speed. The ability to automate repetitive and labor-intensive processes not only reduces production time but also minimizes the risk of human error, leading to improved product quality and consistency. In the aerospace industry, robotic welding equipment is crucial for manufacturing complex components that require high precision and reliability. The stringent quality standards and the need for lightweight yet strong materials make robotic welding an ideal solution for joining aerospace components. These systems are capable of performing intricate welds with minimal heat distortion, ensuring the structural integrity of critical parts. In the automotive sector, robotic welding equipment is indispensable for mass production and assembly line operations. The ability to perform spot welding and arc welding with high accuracy and speed is essential for producing vehicles efficiently and cost-effectively. Robotic systems ensure uniformity in welds, contributing to the overall safety and durability of the vehicles. Additionally, the flexibility of robotic welding equipment allows manufacturers to adapt to changing production requirements and incorporate new materials and designs. Beyond these sectors, robotic welding equipment is also used in industries such as electronics, appliances, and energy. In electronics, the precision and control offered by robotic systems are essential for assembling delicate components and ensuring reliable connections. In the appliance industry, robotic welding is used to join metal parts with high efficiency, contributing to the durability and performance of the final products. In the energy sector, robotic welding equipment is employed in the construction and maintenance of infrastructure, such as pipelines and power plants, where reliability and safety are paramount. Overall, the Global Robotic Welding Equipment Market plays a vital role in enhancing productivity, quality, and safety across various industries, driving innovation and competitiveness in the global market.

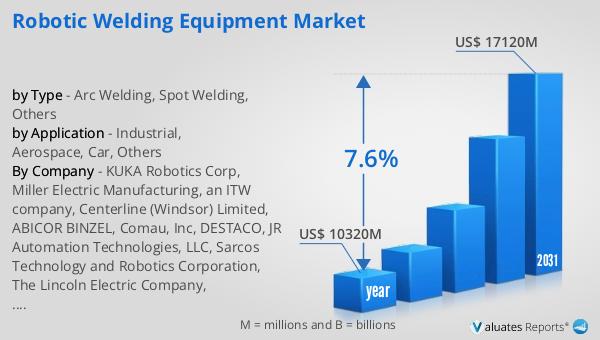

Global Robotic Welding Equipment Market Outlook:

The global market for Robotic Welding Equipment was valued at approximately $10,320 million in 2024, with expectations to grow to a revised size of around $17,120 million by 2031. This growth is projected to occur at a compound annual growth rate (CAGR) of 7.6% during the forecast period. In 2019, the top five players in the market accounted for 38% of the total revenue share, indicating a significant concentration of market power among leading companies. The arc welding segment emerged as the dominant force in the market, capturing nearly 59% of the sales volume share in 2019. This highlights the widespread adoption and preference for arc welding techniques in various industrial applications. The market's expansion is driven by the increasing demand for automation and precision in welding processes, as well as the growing complexity of products that require reliable and efficient welding solutions. As industries continue to embrace advanced technologies and automation practices, the Global Robotic Welding Equipment Market is poised for substantial growth, offering opportunities for innovation and development in the coming years.

| Report Metric | Details |

| Report Name | Robotic Welding Equipment Market |

| Accounted market size in year | US$ 10320 million |

| Forecasted market size in 2031 | US$ 17120 million |

| CAGR | 7.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KUKA Robotics Corp, Miller Electric Manufacturing, an ITW company, Centerline (Windsor) Limited, ABICOR BINZEL, Comau, Inc, DESTACO, JR Automation Technologies, LLC, Sarcos Technology and Robotics Corporation, The Lincoln Electric Company, SourceOne, Genesis Systems Group, Advanced Manufacturing Development, Chain We Machinery Co., LTD, ATI Industrial Automation, Productivity, Inc, Universal Robots USA, Inc, Fronius USA LLC - Perfect Welding Business Unit, Tennessee Rand Inc, Weldlogic, Inc, Orbitform Group, Motion Index Drives, Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |