What is Global Rigid Chilled Food Packaging Market?

The Global Rigid Chilled Food Packaging Market refers to the industry focused on packaging solutions specifically designed for chilled food products that require a stable and protective environment to maintain their freshness and quality. This market encompasses a variety of packaging materials and technologies that are used to store and transport perishable food items at low temperatures. Rigid packaging, as opposed to flexible packaging, provides a sturdy and durable structure that can withstand the rigors of transportation and handling while ensuring the integrity of the food product inside. The demand for such packaging solutions is driven by the increasing consumption of chilled and frozen foods, which are popular due to their convenience and longer shelf life. As consumers become more health-conscious and seek fresh and minimally processed foods, the need for effective packaging that can preserve the nutritional value and taste of these products becomes paramount. The market is characterized by continuous innovation, with manufacturers striving to develop packaging that is not only functional but also environmentally sustainable, catering to the growing demand for eco-friendly solutions. This market plays a crucial role in the global food supply chain, ensuring that chilled food products reach consumers in optimal condition.

Plastic, Metal, Paper, Glass, Others in the Global Rigid Chilled Food Packaging Market:

In the Global Rigid Chilled Food Packaging Market, various materials are utilized to create packaging solutions that meet the diverse needs of food manufacturers and consumers. Plastic is one of the most commonly used materials due to its versatility, durability, and cost-effectiveness. It offers excellent barrier properties that protect food from moisture, oxygen, and contaminants, thereby extending the shelf life of chilled products. Plastics such as polyethylene terephthalate (PET) and polypropylene (PP) are popular choices for rigid packaging, as they are lightweight and can be easily molded into different shapes and sizes. However, the environmental impact of plastic waste has led to increased scrutiny and a push for more sustainable alternatives. Metal packaging, often made from aluminum or tinplate, provides a robust and tamper-proof solution that is ideal for products requiring a high level of protection. Metal cans and containers are commonly used for chilled beverages and ready-to-eat meals, offering excellent preservation qualities and recyclability. Paper-based packaging, including cardboard and paperboard, is gaining traction as a sustainable option, particularly for products like dairy and bakery items. It is biodegradable and can be easily recycled, aligning with the growing consumer preference for eco-friendly packaging. Glass, although heavier and more fragile, is favored for its premium appearance and ability to preserve the taste and quality of food without chemical interactions. It is often used for high-end products such as gourmet sauces and dairy products. Other materials, such as biodegradable and compostable options, are emerging as innovative solutions to address environmental concerns. These materials are designed to break down naturally, reducing the impact on landfills and promoting a circular economy. The choice of material in rigid chilled food packaging is influenced by factors such as the type of food product, shelf life requirements, cost considerations, and environmental impact. Manufacturers are increasingly adopting a multi-material approach, combining the strengths of different materials to create packaging that meets the functional and sustainability needs of the market. As the industry evolves, the focus on reducing carbon footprints and enhancing recyclability will continue to shape the development of new packaging materials and technologies.

Fruits and Vegetables, Bakery & Confectionery, Meat, Seafood & Poultry, Dairy Foods, Ready to Eat Food in the Global Rigid Chilled Food Packaging Market:

The Global Rigid Chilled Food Packaging Market plays a vital role in preserving the quality and safety of various food categories, including fruits and vegetables, bakery and confectionery, meat, seafood and poultry, dairy foods, and ready-to-eat meals. For fruits and vegetables, rigid packaging provides a protective barrier that helps maintain freshness and prevent spoilage during transportation and storage. It is essential for extending the shelf life of these perishable items, ensuring they reach consumers in optimal condition. In the bakery and confectionery sector, rigid packaging is used to protect delicate pastries, cakes, and chocolates from damage and contamination. It also helps retain the texture and flavor of these products, which is crucial for consumer satisfaction. Meat, seafood, and poultry products require packaging that can withstand low temperatures and prevent the growth of harmful bacteria. Rigid packaging solutions, such as vacuum-sealed containers and trays, are designed to provide an airtight seal that preserves the quality and safety of these protein-rich foods. Dairy foods, including milk, cheese, and yogurt, benefit from rigid packaging that offers excellent barrier properties against light and oxygen, which can degrade the nutritional value and taste of these products. Packaging solutions such as plastic bottles and cartons are commonly used to ensure the freshness and safety of dairy items. Ready-to-eat meals, which are increasingly popular due to their convenience, require packaging that can withstand both refrigeration and microwave heating. Rigid packaging solutions, such as plastic trays and containers, are designed to maintain the integrity of these meals while providing ease of use for consumers. The use of rigid packaging in these food categories is driven by the need to protect and preserve the quality of chilled foods, ensuring they remain safe and enjoyable for consumers. As the demand for convenience and high-quality food products continues to grow, the Global Rigid Chilled Food Packaging Market will play a crucial role in meeting these consumer expectations.

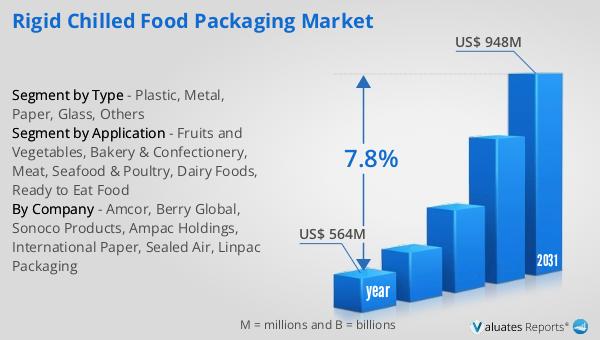

Global Rigid Chilled Food Packaging Market Outlook:

The outlook for the Global Rigid Chilled Food Packaging Market indicates a significant growth trajectory in the coming years. In 2024, the market was valued at approximately US$ 564 million, and it is anticipated to expand to a revised size of US$ 948 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.8% during the forecast period. This upward trend is reflective of the increasing demand for chilled food products and the need for effective packaging solutions that can preserve their quality and extend their shelf life. In parallel, the broader Global Packaging Market is also experiencing growth. In 2023, the market size was estimated at USD 1098.81 billion, with projections indicating an increase to USD 1333.02 billion by 2028, growing at a CAGR of 3.94% during the forecast period from 2023 to 2028. This growth is driven by factors such as the rising consumption of packaged foods, advancements in packaging technologies, and the growing emphasis on sustainability. As consumers continue to prioritize convenience and quality in their food choices, the demand for innovative and sustainable packaging solutions is expected to rise, further propelling the growth of the Global Rigid Chilled Food Packaging Market.

| Report Metric | Details |

| Report Name | Rigid Chilled Food Packaging Market |

| Accounted market size in year | US$ 564 million |

| Forecasted market size in 2031 | US$ 948 million |

| CAGR | 7.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Amcor, Berry Global, Sonoco Products, Ampac Holdings, International Paper, Sealed Air, Linpac Packaging |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |