What is Global Medical Grade High Impact PolyStyrene Market?

The Global Medical Grade High Impact PolyStyrene Market refers to the worldwide industry focused on the production and distribution of a specific type of polystyrene that is engineered to meet the stringent requirements of the medical sector. This material is known for its durability, impact resistance, and versatility, making it ideal for various medical applications. Medical Grade High Impact PolyStyrene is used in the manufacturing of medical devices, packaging, and other healthcare-related products. Its properties allow it to withstand sterilization processes and maintain its integrity under different conditions, which is crucial in medical settings. The market for this material is driven by the growing demand for safe and reliable medical products, advancements in healthcare technology, and the need for cost-effective solutions in the medical industry. As healthcare systems around the world continue to evolve, the demand for high-quality materials like Medical Grade High Impact PolyStyrene is expected to rise, supporting the development of innovative medical solutions.

Extrusion Molding, Injection Molding, Other in the Global Medical Grade High Impact PolyStyrene Market:

Extrusion molding, injection molding, and other molding techniques play a significant role in the Global Medical Grade High Impact PolyStyrene Market. Extrusion molding is a process where the polystyrene material is melted and forced through a die to create long shapes like tubes or sheets. This method is particularly useful for producing continuous profiles and is often used in the creation of medical tubing and other elongated components. The advantage of extrusion molding lies in its ability to produce large volumes of uniform products efficiently, which is essential for meeting the high demands of the medical industry. Injection molding, on the other hand, involves injecting molten polystyrene into a mold cavity where it cools and solidifies into the desired shape. This technique is highly versatile and is used to manufacture a wide range of medical components, from small intricate parts to larger, more complex items. Injection molding is favored for its precision and ability to produce detailed and complex shapes, which are often required in medical devices and equipment. Other molding techniques, such as blow molding and thermoforming, also contribute to the market by offering alternative methods for shaping Medical Grade High Impact PolyStyrene. Blow molding is used to create hollow objects like bottles and containers, which are essential for packaging liquids and other medical substances. Thermoforming involves heating a sheet of polystyrene until it becomes pliable, then forming it over a mold to create a specific shape. This method is commonly used for producing trays, lids, and other packaging solutions. Each of these molding techniques offers unique benefits and is chosen based on the specific requirements of the medical product being manufactured. The choice of molding technique can impact the efficiency, cost, and quality of the final product, making it a critical consideration in the production process. As the demand for medical products continues to grow, the role of these molding techniques in the Global Medical Grade High Impact PolyStyrene Market becomes increasingly important, driving innovation and efficiency in the industry.

Work-in-progress Trays, Thermoformed Pharmaceutical Packaging, Packaging For Economical Medical Devices, Other in the Global Medical Grade High Impact PolyStyrene Market:

The usage of Global Medical Grade High Impact PolyStyrene Market in various areas such as work-in-progress trays, thermoformed pharmaceutical packaging, packaging for economical medical devices, and other applications highlights its versatility and importance in the medical field. Work-in-progress trays are essential in medical settings for organizing and transporting components during the manufacturing process. Medical Grade High Impact PolyStyrene is ideal for these trays due to its durability and ability to withstand repeated use and sterilization. The material's impact resistance ensures that the trays can protect delicate components from damage during handling and transportation. In thermoformed pharmaceutical packaging, Medical Grade High Impact PolyStyrene is used to create blister packs, clamshells, and other packaging solutions that protect medications and ensure their integrity. The material's clarity and strength make it suitable for packaging that requires visibility and protection from external factors. Packaging for economical medical devices also benefits from the properties of Medical Grade High Impact PolyStyrene. The material's cost-effectiveness, combined with its ability to be molded into complex shapes, makes it an attractive option for manufacturers looking to produce affordable yet reliable medical devices. Other applications of this material in the medical field include the production of diagnostic equipment, surgical instruments, and laboratory supplies. Its versatility and adaptability to various manufacturing processes make it a valuable resource for creating a wide range of medical products. As the healthcare industry continues to advance, the demand for high-quality materials like Medical Grade High Impact PolyStyrene is expected to grow, supporting the development of innovative solutions that enhance patient care and safety.

Global Medical Grade High Impact PolyStyrene Market Outlook:

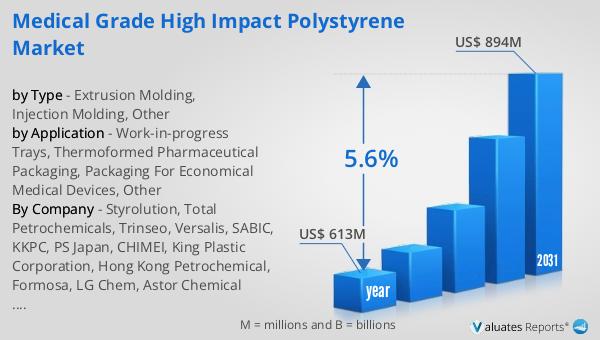

The global market for Medical Grade High Impact PolyStyrene was valued at $613 million in 2024 and is anticipated to expand to a revised size of $894 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period. This growth trajectory underscores the increasing demand for this specialized material in the medical sector. The market's expansion is driven by several factors, including the rising need for durable and reliable materials in medical applications, advancements in healthcare technology, and the ongoing pursuit of cost-effective solutions in the medical industry. As healthcare systems worldwide continue to evolve, the demand for high-quality materials like Medical Grade High Impact PolyStyrene is expected to rise, supporting the development of innovative medical solutions. The projected growth of this market highlights the importance of Medical Grade High Impact PolyStyrene in meeting the needs of the medical industry and its potential to contribute to the advancement of healthcare technologies. As the market continues to grow, manufacturers and suppliers of Medical Grade High Impact PolyStyrene will play a crucial role in ensuring the availability of this essential material for various medical applications.

| Report Metric | Details |

| Report Name | Medical Grade High Impact PolyStyrene Market |

| Accounted market size in year | US$ 613 million |

| Forecasted market size in 2031 | US$ 894 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Styrolution, Total Petrochemicals, Trinseo, Versalis, SABIC, KKPC, PS Japan, CHIMEI, King Plastic Corporation, Hong Kong Petrochemical, Formosa, LG Chem, Astor Chemical Industrial |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |