What is Global Die Attach Film Tape Market?

The Global Die Attach Film Tape Market is a specialized segment within the broader electronics and semiconductor industry. This market focuses on the production and distribution of die attach film tapes, which are essential materials used in the assembly of semiconductor devices. These tapes serve as adhesives that bond semiconductor chips to substrates, ensuring stability and performance in electronic components. The demand for die attach film tapes is driven by the growing need for miniaturization and enhanced performance in electronic devices, such as smartphones, tablets, and other consumer electronics. As technology advances, the requirements for these tapes become more stringent, necessitating innovations in their composition and application techniques. The market is characterized by a diverse range of products, each tailored to specific applications and performance criteria. Key players in the industry are continuously investing in research and development to improve the thermal and electrical conductivity of these tapes, thereby enhancing the overall efficiency of electronic devices. The market's growth is also influenced by the increasing adoption of advanced packaging technologies, which require high-performance die attach materials. Overall, the Global Die Attach Film Tape Market is poised for significant growth, driven by technological advancements and the expanding electronics industry.

Non-Conductive Type, Conductive Type in the Global Die Attach Film Tape Market:

In the Global Die Attach Film Tape Market, two primary types of tapes are utilized: Non-Conductive Type and Conductive Type. Non-Conductive Die Attach Film Tapes are primarily used in applications where electrical insulation is crucial. These tapes are designed to provide strong adhesion between the die and the substrate without conducting electricity, making them ideal for use in devices where electrical isolation is necessary. They are often used in consumer electronics, automotive electronics, and other applications where maintaining electrical separation between components is essential. The non-conductive nature of these tapes ensures that there is no unintended electrical connection between the die and the substrate, which could potentially lead to device failure. On the other hand, Conductive Die Attach Film Tapes are engineered to provide both adhesion and electrical conductivity. These tapes are used in applications where it is necessary to establish an electrical connection between the die and the substrate. Conductive tapes are typically used in power devices, RF components, and other applications where efficient heat dissipation and electrical connectivity are required. The conductive properties of these tapes help in reducing thermal resistance and improving the overall performance of the device. The choice between non-conductive and conductive die attach film tapes depends on the specific requirements of the application, including factors such as thermal management, electrical insulation, and mechanical stability. Manufacturers in the Global Die Attach Film Tape Market are continually innovating to enhance the performance characteristics of both types of tapes, ensuring they meet the evolving needs of the electronics industry. As the demand for more compact and efficient electronic devices grows, the importance of selecting the appropriate die attach film tape becomes increasingly critical. Both non-conductive and conductive tapes play a vital role in the assembly and performance of modern electronic devices, and their development is closely tied to advancements in semiconductor technology.

Die to Substrate, Die to Die, Others in the Global Die Attach Film Tape Market:

The Global Die Attach Film Tape Market finds its applications in various areas, including Die to Substrate, Die to Die, and others. In the Die to Substrate application, die attach film tapes are used to bond semiconductor chips directly to a substrate, which serves as the foundation for the electronic device. This application is critical in ensuring the mechanical stability and thermal management of the device. The tape provides a strong adhesive bond that holds the die in place, while also facilitating efficient heat dissipation from the die to the substrate. This is particularly important in high-performance devices where heat management is crucial to maintaining optimal functionality. In the Die to Die application, die attach film tapes are used to bond multiple semiconductor dies together. This is often seen in advanced packaging technologies, such as multi-chip modules and system-in-package configurations, where multiple dies are integrated into a single package. The use of die attach film tapes in this application ensures that the dies are securely bonded, allowing for efficient electrical and thermal connectivity between them. This is essential for achieving the desired performance and reliability in complex electronic systems. Other applications of die attach film tapes include their use in bonding components within sensors, LEDs, and other electronic devices. In these applications, the tapes provide the necessary adhesion and thermal management to ensure the proper functioning of the device. The versatility of die attach film tapes makes them suitable for a wide range of applications, each with its own set of requirements and challenges. As the electronics industry continues to evolve, the demand for high-performance die attach film tapes in these applications is expected to grow, driving further innovation and development in the market.

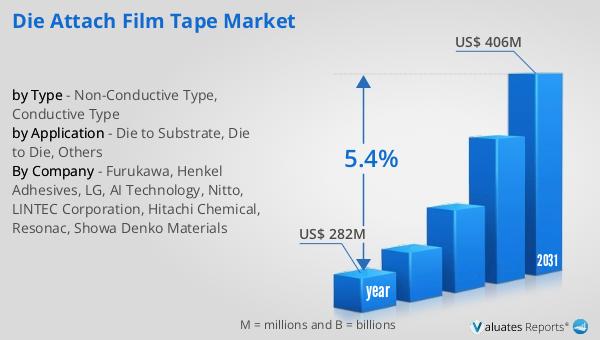

Global Die Attach Film Tape Market Outlook:

The global market for Die Attach Film Tape was valued at $282 million in 2024 and is anticipated to expand to a revised size of $406 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.4% during the forecast period. The Asia Pacific region, which is the largest market, experienced a decline of 2.0 percent. In contrast, sales in the Americas reached $142.1 billion, marking a significant year-on-year increase of 17.0%. Similarly, sales in Europe amounted to $53.8 billion, up 12.6% year-on-year, while sales in Japan were $48.1 billion, reflecting a 10.0% year-on-year growth. However, the Asia Pacific region, despite being the largest market, saw sales of $336.2 billion, which was a 2.0% decrease year-on-year. This market outlook highlights the dynamic nature of the Die Attach Film Tape Market, with varying growth rates across different regions. The overall growth trajectory of the market is positive, driven by increasing demand for advanced electronic devices and the continuous development of semiconductor technologies. The regional variations in sales performance underscore the importance of understanding local market dynamics and tailoring strategies to capitalize on growth opportunities in different parts of the world.

| Report Metric | Details |

| Report Name | Die Attach Film Tape Market |

| Accounted market size in year | US$ 282 million |

| Forecasted market size in 2031 | US$ 406 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Furukawa, Henkel Adhesives, LG, AI Technology, Nitto, LINTEC Corporation, Hitachi Chemical, Resonac, Showa Denko Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |