What is Global Parallel Plate Plastometer Market?

The Global Parallel Plate Plastometer Market is a specialized segment within the broader materials testing industry, focusing on devices used to measure the flow properties of polymers. These plastometers are essential in determining the melt flow index (MFI) of plastic materials, which is a critical parameter for manufacturers and researchers working with polymers. The market for these devices is driven by the increasing demand for high-quality plastic products across various industries, including automotive, packaging, and consumer goods. As industries continue to innovate and develop new polymer materials, the need for precise and reliable testing equipment like parallel plate plastometers becomes even more crucial. These devices help ensure that materials meet specific standards and performance criteria, which is vital for maintaining product quality and safety. The market is characterized by a mix of established players and new entrants, all striving to offer advanced features and improved accuracy in their products. Technological advancements, such as digital interfaces and automated testing capabilities, are also influencing the market dynamics, making these devices more user-friendly and efficient. Overall, the Global Parallel Plate Plastometer Market is poised for steady growth as the demand for high-performance polymers continues to rise.

Benchtop, Floor-Type in the Global Parallel Plate Plastometer Market:

In the Global Parallel Plate Plastometer Market, benchtop and floor-type models represent two primary categories of these testing devices, each catering to different user needs and operational environments. Benchtop plastometers are compact and designed for use in laboratories or small-scale production facilities where space is limited. These models are typically favored for their ease of use, portability, and cost-effectiveness. They are ideal for routine testing and quality control processes, allowing technicians to quickly assess the melt flow properties of polymers without the need for extensive setup or calibration. Benchtop models often come equipped with digital displays and user-friendly interfaces, making them accessible even to those with limited technical expertise. On the other hand, floor-type plastometers are larger and more robust, designed for high-volume testing environments such as industrial laboratories or large manufacturing plants. These models offer enhanced durability and can handle a wider range of testing conditions, making them suitable for more demanding applications. Floor-type plastometers often feature advanced automation capabilities, allowing for continuous testing and data collection, which is essential for large-scale production environments where efficiency and accuracy are paramount. The choice between benchtop and floor-type models largely depends on the specific requirements of the user, including the volume of testing, available space, and budget constraints. Both types of plastometers play a crucial role in ensuring the quality and consistency of polymer products, but they do so in different ways. Benchtop models are typically more affordable and easier to integrate into existing laboratory setups, making them a popular choice for smaller operations or those just starting to implement melt flow testing. Their compact size and straightforward operation make them ideal for educational institutions or research facilities where space and resources may be limited. In contrast, floor-type plastometers are often seen as an investment for larger companies that require high-throughput testing capabilities. These models are built to withstand the rigors of continuous use and can accommodate a broader range of sample sizes and testing conditions. They are particularly valuable in industries where precise material specifications are critical, such as automotive or aerospace manufacturing. The advanced features of floor-type plastometers, such as automated sample handling and integrated data management systems, help streamline the testing process and reduce the potential for human error. As the Global Parallel Plate Plastometer Market continues to evolve, manufacturers are focusing on developing new technologies and features that enhance the functionality and versatility of both benchtop and floor-type models. Innovations such as improved temperature control, faster testing cycles, and enhanced data analysis capabilities are becoming increasingly important as users demand more from their testing equipment. Additionally, the integration of digital technologies and connectivity features is transforming the way these devices are used, allowing for remote monitoring and control, as well as seamless integration with other laboratory systems. This trend towards digitalization is expected to drive further growth in the market, as users seek out more efficient and effective ways to conduct melt flow testing. Ultimately, the choice between benchtop and floor-type plastometers will continue to be influenced by a variety of factors, including the specific needs of the user, the scale of their operations, and the level of precision required. Both types of devices offer unique advantages and play a vital role in the ongoing development and quality assurance of polymer products. As the demand for high-performance materials continues to grow, the Global Parallel Plate Plastometer Market is well-positioned to meet the evolving needs of industries worldwide.

Enterprise, Laboratory, Others in the Global Parallel Plate Plastometer Market:

The Global Parallel Plate Plastometer Market finds its applications across various sectors, including enterprises, laboratories, and other specialized fields, each utilizing these devices to meet specific testing requirements. In enterprise settings, plastometers are primarily used by manufacturers of plastic products to ensure that their materials meet industry standards and performance criteria. These devices help companies maintain consistent product quality by providing accurate measurements of the melt flow index, which is crucial for determining the suitability of polymers for different applications. Enterprises often rely on plastometers to optimize their production processes, reduce material waste, and improve overall efficiency. By understanding the flow properties of their materials, manufacturers can make informed decisions about processing conditions, such as temperature and pressure, to achieve the desired product characteristics. In laboratory environments, parallel plate plastometers are essential tools for research and development activities. Scientists and researchers use these devices to study the behavior of polymers under various conditions, gaining insights into their properties and potential applications. Laboratories often conduct experiments to develop new materials or improve existing ones, and plastometers play a critical role in these efforts by providing reliable data on melt flow characteristics. This information is invaluable for advancing the understanding of polymer science and driving innovation in the field. Additionally, laboratories may use plastometers for quality control purposes, ensuring that materials used in research projects meet specific standards and specifications. Beyond enterprises and laboratories, the Global Parallel Plate Plastometer Market also serves other specialized areas, such as educational institutions and regulatory bodies. In educational settings, plastometers are used as teaching tools to help students learn about polymer properties and testing methods. These devices provide hands-on experience with real-world testing equipment, preparing students for careers in materials science and engineering. Regulatory bodies, on the other hand, may use plastometers to verify compliance with industry standards and regulations, ensuring that products meet safety and performance requirements. This is particularly important in industries where material properties can impact product safety, such as medical devices or food packaging. Overall, the versatility and reliability of parallel plate plastometers make them indispensable tools across a wide range of applications. Whether used for quality control, research and development, or educational purposes, these devices provide valuable insights into the behavior of polymers, helping to drive advancements in materials science and improve product quality. As the demand for high-performance materials continues to grow, the Global Parallel Plate Plastometer Market is expected to play an increasingly important role in supporting the needs of various industries and sectors.

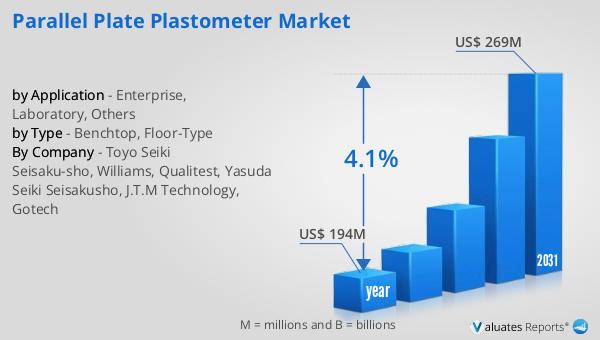

Global Parallel Plate Plastometer Market Outlook:

The outlook for the Global Parallel Plate Plastometer Market indicates a promising future, with the market valued at approximately US$ 194 million in 2024. It is anticipated to expand to a revised size of US$ 269 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.1% over the forecast period. This growth trajectory underscores the increasing demand for precise and reliable testing equipment in the polymer industry. As industries continue to innovate and develop new materials, the need for accurate melt flow testing becomes more critical, driving the demand for parallel plate plastometers. The market's expansion is also fueled by technological advancements that enhance the functionality and efficiency of these devices, making them more accessible and user-friendly. The integration of digital technologies and automation features is transforming the way plastometers are used, allowing for more efficient testing processes and improved data management. This trend towards digitalization is expected to further boost market growth, as users seek out more advanced and efficient testing solutions. Overall, the Global Parallel Plate Plastometer Market is poised for steady growth, driven by the increasing demand for high-performance materials and the ongoing development of new technologies in the field.

| Report Metric | Details |

| Report Name | Parallel Plate Plastometer Market |

| Accounted market size in year | US$ 194 million |

| Forecasted market size in 2031 | US$ 269 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toyo Seiki Seisaku-sho, Williams, Qualitest, Yasuda Seiki Seisakusho, J.T.M Technology, Gotech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |