What is Global Precision Optical Coating Equipment Market?

The Global Precision Optical Coating Equipment Market is a specialized sector within the broader optical technology industry, focusing on the development and production of equipment used to apply thin film coatings to optical components. These coatings are essential for enhancing the performance of optical devices by improving their reflectivity, transmission, and durability. The market encompasses a wide range of equipment, including machines that apply coatings through various methods such as vacuum deposition, sputtering, and chemical vapor deposition. These coatings are used in numerous applications, from enhancing the efficiency of lenses and mirrors to improving the performance of electronic displays and solar panels. The demand for precision optical coating equipment is driven by the growing need for high-performance optical components in industries such as telecommunications, healthcare, and consumer electronics. As technology advances, the precision and complexity of optical coatings continue to increase, necessitating more sophisticated equipment. This market is characterized by rapid technological advancements and a high degree of specialization, with manufacturers focusing on developing equipment that can produce coatings with precise thickness and uniformity. The global reach of this market is expanding as more industries recognize the benefits of advanced optical coatings.

Vacuum Coating Machine, Non-vacuum Coating Machine in the Global Precision Optical Coating Equipment Market:

In the realm of the Global Precision Optical Coating Equipment Market, two primary types of machines are pivotal: Vacuum Coating Machines and Non-vacuum Coating Machines. Vacuum Coating Machines operate by creating a vacuum environment in which materials are deposited onto a substrate. This method is highly effective for producing thin films with precise control over thickness and composition. The vacuum environment minimizes contamination and allows for the deposition of high-purity coatings, making it ideal for applications requiring high optical clarity and performance. Techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) are commonly used in vacuum coating processes. These machines are essential in industries where the highest quality optical coatings are required, such as in the production of high-end lenses, mirrors, and other optical components. On the other hand, Non-vacuum Coating Machines apply coatings without the need for a vacuum environment. These machines often use methods such as dip coating, spray coating, or spin coating. While they may not offer the same level of precision as vacuum coating machines, they are often more cost-effective and suitable for applications where ultra-high precision is not critical. Non-vacuum methods are typically used for applying coatings to larger surfaces or for applications where the coating requirements are less stringent. These machines are commonly found in industries such as automotive, where coatings are applied to enhance the durability and appearance of glass and plastic components. The choice between vacuum and non-vacuum coating machines depends largely on the specific requirements of the application. Vacuum coating machines are preferred for applications demanding high precision and purity, while non-vacuum machines are chosen for their cost-effectiveness and ability to coat larger areas. Both types of machines play a crucial role in the Global Precision Optical Coating Equipment Market, catering to a diverse range of industries and applications. As technology continues to evolve, both vacuum and non-vacuum coating machines are expected to see advancements that will enhance their capabilities and expand their applications. The ongoing development in this market is driven by the need for more efficient, durable, and high-performance optical coatings, which are essential for the advancement of modern technology.

Automotive Industry, Optical Industry, Semiconductor Industry, Consumer Electronics Industry, Others in the Global Precision Optical Coating Equipment Market:

The Global Precision Optical Coating Equipment Market finds extensive usage across various industries, each benefiting from the unique properties that optical coatings provide. In the automotive industry, optical coatings are used to enhance the performance and durability of vehicle components such as windshields, mirrors, and lighting systems. These coatings improve visibility, reduce glare, and protect surfaces from environmental damage, contributing to safer and more efficient vehicles. The demand for advanced optical coatings in the automotive sector is driven by the need for improved safety features and the growing trend towards autonomous vehicles, which require sophisticated optical systems. In the optical industry, precision optical coatings are essential for the production of lenses, mirrors, and other components used in cameras, telescopes, and microscopes. These coatings enhance the performance of optical devices by improving light transmission, reducing reflection, and increasing durability. The optical industry relies heavily on high-quality coatings to produce components that meet the stringent requirements of scientific research, medical imaging, and consumer electronics. The semiconductor industry also benefits significantly from precision optical coatings. These coatings are used in the manufacturing of semiconductor devices to improve their performance and reliability. Optical coatings are applied to photomasks, lenses, and other components used in the photolithography process, which is critical for the production of integrated circuits. The demand for advanced optical coatings in the semiconductor industry is driven by the need for smaller, faster, and more efficient electronic devices. In the consumer electronics industry, optical coatings are used to enhance the performance of displays, touchscreens, and camera lenses. These coatings improve the clarity, brightness, and durability of electronic displays, contributing to a better user experience. The growing demand for high-quality displays in smartphones, tablets, and televisions is driving the need for advanced optical coatings in this industry. Beyond these industries, precision optical coatings are also used in various other applications, including solar panels, architectural glass, and lighting systems. The versatility and performance benefits of optical coatings make them an essential component in a wide range of products and technologies. As industries continue to innovate and develop new applications, the demand for precision optical coatings and the equipment used to produce them is expected to grow.

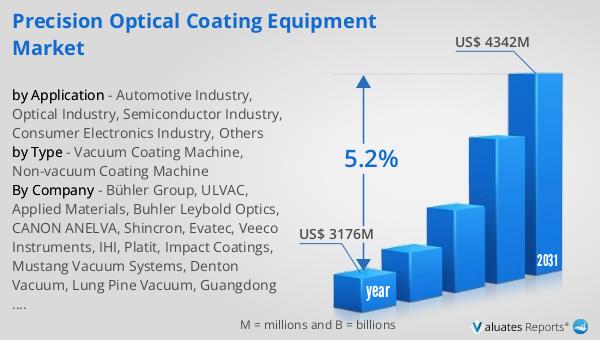

Global Precision Optical Coating Equipment Market Outlook:

The outlook for the Global Precision Optical Coating Equipment Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 3,176 million. By 2031, it is anticipated to expand to a revised size of US$ 4,342 million, reflecting a compound annual growth rate (CAGR) of 5.2% over the forecast period. This growth is driven by the increasing demand for high-performance optical coatings across various industries, including automotive, optical, semiconductor, and consumer electronics. The advancements in technology and the growing need for more efficient and durable optical components are key factors contributing to the market's expansion. As industries continue to innovate and develop new applications for optical coatings, the demand for precision optical coating equipment is expected to rise. The market's growth is also supported by the increasing adoption of advanced manufacturing techniques and the development of new materials that enhance the performance of optical coatings. Overall, the Global Precision Optical Coating Equipment Market is poised for significant growth, driven by the ongoing advancements in technology and the increasing demand for high-quality optical components.

| Report Metric | Details |

| Report Name | Precision Optical Coating Equipment Market |

| Accounted market size in year | US$ 3176 million |

| Forecasted market size in 2031 | US$ 4342 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Bühler Group, ULVAC, Applied Materials, Buhler Leybold Optics, CANON ANELVA, Shincron, Evatec, Veeco Instruments, IHI, Platit, Impact Coatings, Mustang Vacuum Systems, Denton Vacuum, Lung Pine Vacuum, Guangdong HCAVC, Hongda Vacuum, Beijing Power Tech, SKY Technologies, Guangdong Zhenhua, KYZK, GR-VACUUM, Wuxi Xin Giant Macro Intelligent Technology, Chengdu sisheng technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |