What is Global Soft Magnetic Alloy Spherical Powder Market?

The Global Soft Magnetic Alloy Spherical Powder Market is a specialized segment within the broader materials industry, focusing on the production and application of spherical powders made from soft magnetic alloys. These powders are characterized by their ability to enhance magnetic properties, such as permeability and coercivity, which are crucial for efficient energy conversion and electromagnetic applications. The market is driven by the increasing demand for advanced materials in various high-tech industries, including electronics, automotive, and aerospace. Soft magnetic alloy spherical powders are used in the manufacturing of components like inductors, transformers, and magnetic sensors, which are essential for modern electronic devices and systems. The market's growth is fueled by technological advancements and the need for miniaturization and improved performance in electronic components. Additionally, the rise in renewable energy projects and electric vehicles has further propelled the demand for these materials, as they play a vital role in enhancing the efficiency of power conversion systems. The market is characterized by continuous research and development efforts aimed at improving the properties of these powders to meet the evolving needs of various industries.

Aerosolized Powder, Water Atomized Powder, Mechanically Alloyed Powder in the Global Soft Magnetic Alloy Spherical Powder Market:

Aerosolized Powder, Water Atomized Powder, and Mechanically Alloyed Powder are three distinct types of powders used in the Global Soft Magnetic Alloy Spherical Powder Market, each with unique characteristics and applications. Aerosolized Powder is produced through a process that involves the dispersion of molten metal into fine droplets, which are then rapidly cooled to form spherical particles. This method is known for producing powders with high purity and uniform particle size distribution, making them ideal for applications requiring precise magnetic properties. These powders are often used in high-frequency applications where low core loss and high permeability are essential. Water Atomized Powder, on the other hand, is created by disintegrating molten metal using high-pressure water jets. This process results in powders with irregular shapes and a wide range of particle sizes. While they may not have the same level of purity as aerosolized powders, water atomized powders are cost-effective and suitable for applications where high volume and moderate performance are required. They are commonly used in the production of magnetic cores for transformers and inductors. Mechanically Alloyed Powder is produced through a solid-state process that involves repeated welding, fracturing, and re-welding of powder particles in a high-energy ball mill. This method allows for the creation of unique alloy compositions that are not achievable through conventional melting techniques. Mechanically alloyed powders are known for their enhanced mechanical and magnetic properties, making them suitable for demanding applications in the aerospace and automotive industries. These powders are often used in the production of high-performance magnetic components that require superior strength and durability. Each type of powder offers distinct advantages and is chosen based on the specific requirements of the application, such as cost, performance, and manufacturing process compatibility. The choice of powder type is crucial in determining the efficiency and effectiveness of the final product, as it directly impacts the magnetic properties and overall performance of the components in which they are used.

Electric Power Industry, Electronic Industry, Automotive Industry, Communication Industry, Aerospace Industry, Others in the Global Soft Magnetic Alloy Spherical Powder Market:

The Global Soft Magnetic Alloy Spherical Powder Market finds extensive usage across various industries, each leveraging the unique properties of these materials to enhance performance and efficiency. In the Electric Power Industry, these powders are crucial for the development of transformers and inductors, which are essential for efficient power transmission and distribution. The high permeability and low core loss of soft magnetic alloys enable the production of components that minimize energy loss, thereby improving the overall efficiency of power systems. In the Electronic Industry, soft magnetic alloy spherical powders are used in the manufacturing of magnetic sensors, inductors, and transformers that are integral to modern electronic devices. These components are essential for the miniaturization of electronic circuits and the enhancement of signal processing capabilities. The Automotive Industry utilizes these powders in the production of electric motors and sensors, which are critical for the development of electric and hybrid vehicles. The improved magnetic properties of these materials contribute to the efficiency and performance of automotive systems, leading to reduced energy consumption and enhanced vehicle performance. In the Communication Industry, soft magnetic alloy spherical powders are used in the production of components that facilitate efficient signal transmission and reception. These materials are essential for the development of high-frequency communication devices, ensuring reliable and fast data transfer. The Aerospace Industry benefits from the use of these powders in the production of lightweight and high-performance magnetic components that are crucial for the operation of aircraft and spacecraft. The unique properties of soft magnetic alloys enable the development of components that withstand extreme conditions while maintaining optimal performance. Additionally, other industries, such as renewable energy and medical devices, also utilize these powders to enhance the efficiency and performance of their systems. The versatility and adaptability of soft magnetic alloy spherical powders make them indispensable in various applications, driving innovation and technological advancement across multiple sectors.

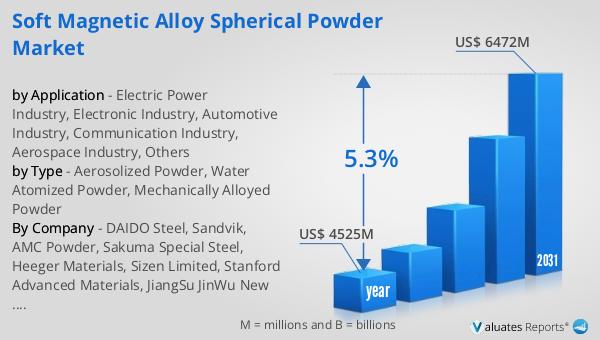

Global Soft Magnetic Alloy Spherical Powder Market Outlook:

The global market for Soft Magnetic Alloy Spherical Powder was valued at $4,525 million in 2024 and is anticipated to expand to a revised size of $6,472 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.3% over the forecast period. This growth trajectory underscores the increasing demand for advanced materials that enhance the efficiency and performance of electronic and electromagnetic applications. The market's expansion is driven by the rising adoption of electric vehicles, renewable energy projects, and the continuous miniaturization of electronic devices, all of which require high-performance magnetic components. The consistent growth rate highlights the importance of ongoing research and development efforts aimed at improving the properties of soft magnetic alloy spherical powders to meet the evolving needs of various industries. As industries continue to seek materials that offer superior magnetic properties, the demand for these powders is expected to remain robust. The market's growth is also supported by the increasing focus on energy efficiency and sustainability, as these powders play a crucial role in reducing energy loss and enhancing the performance of power conversion systems. Overall, the positive market outlook reflects the critical role that soft magnetic alloy spherical powders play in driving innovation and technological advancement across multiple sectors.

| Report Metric | Details |

| Report Name | Soft Magnetic Alloy Spherical Powder Market |

| Accounted market size in year | US$ 4525 million |

| Forecasted market size in 2031 | US$ 6472 million |

| CAGR | 5.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DAIDO Steel, Sandvik, AMC Powder, Sakuma Special Steel, Heeger Materials, Sizen Limited, Stanford Advanced Materials, JiangSu JinWu New Material, HLPOWDER, GRIPM Advanced Materials, POCO Holding, HUNAN FINEPOWD MATERIAL, Yuean Metal, Advanced Technology and Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |