What is Global AC Electric Arc Furnace Market?

The Global AC Electric Arc Furnace Market refers to the worldwide industry focused on the production and sale of AC electric arc furnaces, which are crucial in the steelmaking process. These furnaces use electrical energy to melt scrap steel and convert it into liquid steel, offering a more energy-efficient and environmentally friendly alternative to traditional blast furnaces. The market encompasses various types of furnaces, each designed to handle different capacities and specific industrial needs. As industries worldwide strive for more sustainable and cost-effective production methods, the demand for AC electric arc furnaces has been steadily increasing. This growth is driven by the rising need for steel in construction, automotive, and manufacturing sectors, coupled with technological advancements that enhance furnace efficiency and reduce operational costs. The market is characterized by a diverse range of manufacturers and suppliers, each offering innovative solutions to meet the evolving demands of steel producers. As a result, the Global AC Electric Arc Furnace Market plays a pivotal role in shaping the future of steel production, contributing to the global push towards more sustainable industrial practices.

Capacity: Less than 50 Tons, Capacity: 50 to 100 Tons, Capacity: 100 to 200 Tons, Capacity: 200 to 400 Tons, Capacity: More than 400 Tons in the Global AC Electric Arc Furnace Market:

In the Global AC Electric Arc Furnace Market, furnaces are categorized based on their capacity, which determines the amount of steel they can process at a time. Furnaces with a capacity of less than 50 tons are typically used by smaller steel producers or in facilities where space and energy constraints limit the use of larger equipment. These smaller furnaces are ideal for specialized applications or for producing smaller batches of steel, offering flexibility and efficiency for niche markets. Moving up the scale, furnaces with a capacity of 50 to 100 tons are more common in medium-sized operations. They strike a balance between production volume and operational efficiency, making them suitable for a wide range of industrial applications. These furnaces are often used in regional steel mills that supply local construction and manufacturing industries. Furnaces with a capacity of 100 to 200 tons are designed for larger steel production facilities. They offer increased output and are capable of handling more significant production demands, making them essential for meeting the needs of large-scale construction projects and automotive manufacturing. These furnaces are often equipped with advanced technologies to optimize energy use and reduce emissions, aligning with global sustainability goals. As we move to even larger capacities, furnaces with a capacity of 200 to 400 tons are used by major steel producers with extensive production requirements. These furnaces are integral to the operations of large steel plants, providing the high volume output needed to supply national and international markets. They are often part of integrated steelmaking facilities that include additional processing equipment to refine and shape the steel. Finally, furnaces with a capacity of more than 400 tons represent the pinnacle of steel production technology. These massive furnaces are used by the largest steel manufacturers in the world, capable of producing vast quantities of steel to meet global demand. They incorporate the latest advancements in furnace design and control systems, ensuring maximum efficiency and minimal environmental impact. These furnaces are critical to the infrastructure and development projects that drive economic growth worldwide. Each capacity category within the Global AC Electric Arc Furnace Market serves a specific purpose, catering to the diverse needs of the steel industry and contributing to the overall efficiency and sustainability of steel production.

Metal Smelting, Ore Smelting, Others in the Global AC Electric Arc Furnace Market:

The Global AC Electric Arc Furnace Market finds its usage in various areas, with metal smelting being one of the primary applications. In metal smelting, these furnaces are used to melt scrap metal and convert it into liquid steel, which can then be cast into various shapes and sizes. This process is essential for recycling metal and reducing the need for raw material extraction, making it a more sustainable option for steel production. The efficiency and precision of AC electric arc furnaces make them ideal for producing high-quality steel with consistent properties, which is crucial for industries such as construction, automotive, and manufacturing. In ore smelting, AC electric arc furnaces are used to extract metals from their ores. This process involves heating the ore to high temperatures to separate the metal from impurities, resulting in pure metal that can be used for various industrial applications. The ability of these furnaces to reach extremely high temperatures makes them suitable for smelting a wide range of ores, including iron, copper, and nickel. This versatility is particularly important in regions where ore quality varies, as it allows producers to adapt their processes to different raw materials. Beyond metal and ore smelting, AC electric arc furnaces are also used in other applications, such as the production of ferroalloys and the recycling of electronic waste. In ferroalloy production, these furnaces are used to combine different metals to create alloys with specific properties, which are essential for producing high-strength steel and other advanced materials. The precision and control offered by AC electric arc furnaces ensure that the resulting alloys meet the stringent quality standards required by modern industries. In electronic waste recycling, these furnaces play a crucial role in recovering valuable metals from discarded electronic devices. By melting down the waste, the furnaces can separate and purify metals such as gold, silver, and copper, which can then be reused in new products. This process not only reduces the environmental impact of electronic waste but also provides a valuable source of raw materials for the electronics industry. Overall, the Global AC Electric Arc Furnace Market plays a vital role in various industrial processes, contributing to the efficient and sustainable production of metals and alloys.

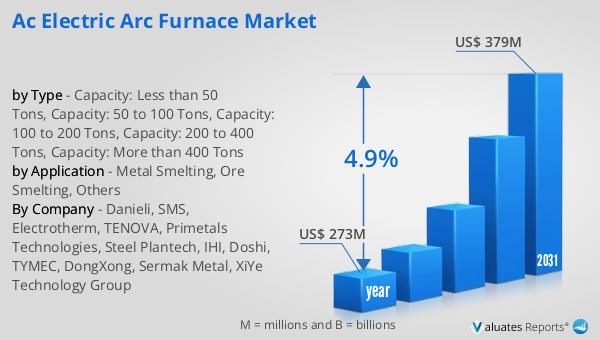

Global AC Electric Arc Furnace Market Outlook:

The global market for AC Electric Arc Furnaces was valued at $273 million in 2024, and it is anticipated to grow significantly, reaching an estimated value of $379 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.9% over the forecast period. The increasing demand for steel across various industries, such as construction, automotive, and manufacturing, is a key driver of this market expansion. As industries continue to seek more sustainable and cost-effective production methods, the adoption of AC electric arc furnaces is expected to rise. These furnaces offer numerous advantages, including energy efficiency, reduced emissions, and the ability to recycle scrap metal, making them an attractive option for steel producers worldwide. Additionally, technological advancements in furnace design and control systems are enhancing their performance and reliability, further boosting their appeal in the market. The growing emphasis on environmental sustainability and the need to reduce carbon footprints are also contributing to the increased adoption of AC electric arc furnaces. As a result, the Global AC Electric Arc Furnace Market is poised for steady growth, driven by the ongoing demand for steel and the continuous evolution of furnace technology.

| Report Metric | Details |

| Report Name | AC Electric Arc Furnace Market |

| Accounted market size in year | US$ 273 million |

| Forecasted market size in 2031 | US$ 379 million |

| CAGR | 4.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Danieli, SMS, Electrotherm, TENOVA, Primetals Technologies, Steel Plantech, IHI, Doshi, TYMEC, DongXong, Sermak Metal, XiYe Technology Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |