What is Global Ultrasonic Welding Technology Market?

The Global Ultrasonic Welding Technology Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries worldwide. Ultrasonic welding is a process that uses high-frequency ultrasonic acoustic vibrations to create solid-state welds between materials, typically plastics or metals, without the need for additional adhesives or soldering materials. This technology is highly valued for its efficiency, precision, and ability to produce strong, reliable joints. The market for ultrasonic welding technology is driven by the increasing demand for lightweight, durable, and environmentally friendly products across industries such as automotive, electronics, medical devices, and packaging. As manufacturers seek to improve production efficiency and product quality, the adoption of ultrasonic welding technology continues to grow. The market is characterized by continuous innovation, with companies investing in research and development to enhance the capabilities and applications of ultrasonic welding systems. This growth is further supported by the global trend towards automation and smart manufacturing, where ultrasonic welding technology is integrated into automated production lines to streamline operations and reduce costs. Overall, the Global Ultrasonic Welding Technology Market is poised for significant expansion as industries continue to recognize the benefits of this advanced joining technique.

Ultrasonic Plastic Welding, Ultrasonic Metal Welding in the Global Ultrasonic Welding Technology Market:

Ultrasonic welding is a versatile and efficient process used to join materials, primarily plastics and metals, through the application of high-frequency ultrasonic vibrations. In the context of the Global Ultrasonic Welding Technology Market, this process is divided into two main categories: Ultrasonic Plastic Welding and Ultrasonic Metal Welding. Ultrasonic Plastic Welding is widely used in industries where the joining of thermoplastic materials is required. This process involves the conversion of high-frequency electrical energy into mechanical vibrations, which are then applied to the plastic parts to be joined. The friction generated by these vibrations causes the plastic to melt at the interface, creating a strong bond upon cooling. This method is favored for its speed, cleanliness, and ability to produce consistent, high-quality welds without the need for additional materials. It is commonly used in the automotive industry for assembling components such as dashboards, door panels, and airbag housings. In the medical field, ultrasonic plastic welding is employed to manufacture devices like IV catheters, filters, and fluid delivery systems, where precision and hygiene are paramount. Ultrasonic Metal Welding, on the other hand, is used to join metal components, often in applications where traditional welding methods may be unsuitable. This process is particularly effective for joining thin or dissimilar metals, as it does not require melting the materials. Instead, ultrasonic vibrations create a solid-state bond through the application of pressure and high-frequency energy. This technique is highly valued in the electronics industry for assembling components such as battery tabs, wire harnesses, and circuit connections, where heat-sensitive materials are involved. The automotive sector also benefits from ultrasonic metal welding, particularly in the production of lightweight, high-strength components for electric vehicles. The Global Ultrasonic Welding Technology Market is driven by the increasing demand for efficient, reliable, and environmentally friendly joining solutions across various industries. As manufacturers seek to improve production efficiency and product quality, the adoption of ultrasonic welding technology continues to grow. This growth is further supported by advancements in automation and smart manufacturing, where ultrasonic welding systems are integrated into automated production lines to streamline operations and reduce costs. Companies in the market are investing in research and development to enhance the capabilities and applications of ultrasonic welding systems, leading to continuous innovation and expansion of the market. Overall, the Global Ultrasonic Welding Technology Market is poised for significant growth as industries continue to recognize the benefits of this advanced joining technique.

Auto Parts, Medical Instruments, Communication Equipment, Others in the Global Ultrasonic Welding Technology Market:

The Global Ultrasonic Welding Technology Market finds extensive application across various sectors, including automotive parts, medical instruments, communication equipment, and others. In the automotive industry, ultrasonic welding is a preferred method for assembling plastic and metal components due to its ability to produce strong, reliable joints without the need for additional adhesives or fasteners. This technology is used to manufacture a wide range of automotive parts, such as dashboards, door panels, airbag housings, and electrical connections. The precision and speed of ultrasonic welding make it ideal for high-volume production environments, where efficiency and quality are paramount. In the medical field, ultrasonic welding is employed to produce a variety of medical instruments and devices. The process is highly valued for its ability to create hermetic seals and strong bonds without introducing contaminants, making it suitable for applications where hygiene and precision are critical. Medical devices such as IV catheters, fluid delivery systems, and surgical instruments are commonly manufactured using ultrasonic welding technology. The communication equipment sector also benefits from ultrasonic welding, particularly in the assembly of electronic components and devices. The process is used to join delicate and heat-sensitive materials, such as circuit boards and connectors, without causing damage. This capability is essential in the production of high-performance communication devices, where reliability and precision are crucial. Beyond these specific industries, ultrasonic welding technology is utilized in various other applications, including consumer electronics, packaging, and textiles. In the electronics industry, ultrasonic welding is used to assemble components such as battery packs, wire harnesses, and sensors, where strong, reliable connections are required. The packaging industry benefits from ultrasonic welding's ability to create airtight seals, which are essential for preserving the integrity and freshness of packaged goods. In the textile industry, ultrasonic welding is used to bond synthetic fabrics, creating seamless and durable products without the need for stitching. Overall, the Global Ultrasonic Welding Technology Market is characterized by its versatility and adaptability across a wide range of applications. As industries continue to seek efficient, reliable, and environmentally friendly joining solutions, the adoption of ultrasonic welding technology is expected to grow. This growth is further supported by advancements in automation and smart manufacturing, where ultrasonic welding systems are integrated into automated production lines to streamline operations and reduce costs. Companies in the market are investing in research and development to enhance the capabilities and applications of ultrasonic welding systems, leading to continuous innovation and expansion of the market. As a result, the Global Ultrasonic Welding Technology Market is poised for significant growth as industries continue to recognize the benefits of this advanced joining technique.

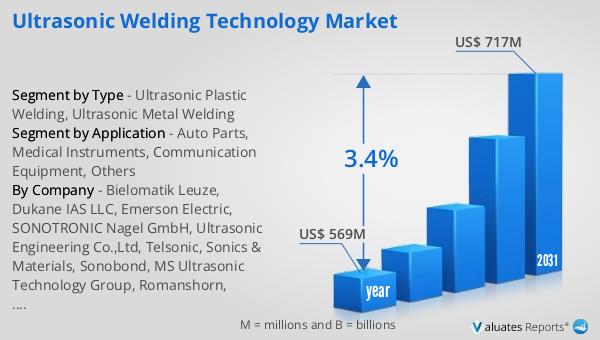

Global Ultrasonic Welding Technology Market Outlook:

The global market for Ultrasonic Welding Technology was valued at $569 million in 2024, and it is anticipated to expand to a revised size of $717 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.4% during the forecast period. This growth trajectory underscores the increasing demand for ultrasonic welding technology across various industries, driven by its efficiency, precision, and ability to produce strong, reliable joints without the need for additional adhesives or soldering materials. The market is characterized by a high level of competition, with the top five manufacturers holding a significant share of over 42%. This concentration of market power highlights the importance of innovation and differentiation for companies operating in this space. As industries continue to seek efficient, reliable, and environmentally friendly joining solutions, the adoption of ultrasonic welding technology is expected to grow. This growth is further supported by advancements in automation and smart manufacturing, where ultrasonic welding systems are integrated into automated production lines to streamline operations and reduce costs. Companies in the market are investing in research and development to enhance the capabilities and applications of ultrasonic welding systems, leading to continuous innovation and expansion of the market. Overall, the Global Ultrasonic Welding Technology Market is poised for significant growth as industries continue to recognize the benefits of this advanced joining technique.

| Report Metric | Details |

| Report Name | Ultrasonic Welding Technology Market |

| Accounted market size in year | US$ 569 million |

| Forecasted market size in 2031 | US$ 717 million |

| CAGR | 3.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Bielomatik Leuze, Dukane IAS LLC, Emerson Electric, SONOTRONIC Nagel GmbH, Ultrasonic Engineering Co.,Ltd, Telsonic, Sonics & Materials, Sonobond, MS Ultrasonic Technology Group, Romanshorn, SONIMAT, Forward Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |