What is Global PFA High Purity Tubing Market?

The Global PFA High Purity Tubing Market is a specialized segment within the broader tubing industry, focusing on the production and distribution of tubing made from Perfluoroalkoxy (PFA) resin. PFA is a type of fluoropolymer known for its high resistance to heat, chemical inertness, and excellent electrical insulation properties. These characteristics make PFA tubing ideal for applications requiring high purity and resistance to harsh environments. The market for PFA high purity tubing is driven by its demand in industries such as semiconductors, pharmaceuticals, and food processing, where contamination-free processes are critical. The tubing is used in various applications, including fluid handling systems, chemical processing, and laboratory equipment. The global market is characterized by a growing need for high-performance materials that can withstand extreme conditions while maintaining purity and integrity. As industries continue to advance technologically, the demand for PFA high purity tubing is expected to rise, driven by the need for reliable and durable materials that ensure the safety and efficiency of critical processes.

Inner Diameter: 50μm, Inner Diameter: 75μm, Inner Diameter: 100μm, Others in the Global PFA High Purity Tubing Market:

In the Global PFA High Purity Tubing Market, the inner diameter of the tubing plays a crucial role in determining its suitability for various applications. Tubing with an inner diameter of 50μm is typically used in applications requiring precise fluid control and minimal flow rates. This size is ideal for microfluidic systems, where small volumes of fluids need to be transported with high accuracy. The 50μm tubing is also used in analytical instruments and laboratory equipment, where precision and purity are paramount. On the other hand, tubing with an inner diameter of 75μm offers a balance between flow rate and precision, making it suitable for applications that require moderate fluid handling capabilities. This size is often used in semiconductor manufacturing processes, where it is essential to maintain a controlled environment to prevent contamination. The 75μm tubing is also used in pharmaceutical applications, where it is crucial to ensure the purity and integrity of the fluids being transported. Tubing with an inner diameter of 100μm is designed for applications that require higher flow rates while still maintaining a high level of purity. This size is commonly used in the food industry, where it is essential to transport large volumes of fluids without compromising on quality. The 100μm tubing is also used in chemical processing, where it is necessary to handle aggressive chemicals safely. In addition to these standard sizes, the Global PFA High Purity Tubing Market also offers tubing with other inner diameters to cater to specific industry needs. These custom sizes are designed to meet the unique requirements of various applications, ensuring that the tubing can perform optimally in different environments. The availability of a wide range of inner diameters allows manufacturers to provide tailored solutions to their customers, enhancing the versatility and applicability of PFA high purity tubing across different industries. As the demand for high-performance materials continues to grow, the Global PFA High Purity Tubing Market is expected to expand, driven by the need for reliable and durable tubing solutions that can withstand the challenges of modern industrial processes.

Semiconductors, Pharmaceutical Industry, Food Industry in the Global PFA High Purity Tubing Market:

The Global PFA High Purity Tubing Market finds extensive usage in several critical industries, including semiconductors, pharmaceuticals, and the food industry, due to its exceptional properties. In the semiconductor industry, PFA high purity tubing is indispensable for maintaining the purity and integrity of chemical processes. The tubing is used in the transport of ultra-pure chemicals and gases, which are essential for the production of semiconductor devices. Its chemical inertness and resistance to high temperatures make it ideal for use in cleanroom environments, where contamination can lead to significant defects in semiconductor products. The tubing's ability to withstand aggressive chemicals ensures that it can handle the demanding conditions of semiconductor manufacturing processes without compromising on performance. In the pharmaceutical industry, PFA high purity tubing is used to ensure the safe and contamination-free transport of sensitive fluids and gases. The tubing's non-reactive nature and high purity levels make it suitable for use in the production of pharmaceuticals, where maintaining the integrity of the product is crucial. It is used in various applications, including fluid transfer systems, bioreactors, and laboratory equipment, where it is essential to prevent any interaction between the tubing material and the substances being transported. The tubing's flexibility and durability also make it ideal for use in dynamic environments, where it can withstand repeated bending and movement without compromising on performance. In the food industry, PFA high purity tubing is used to ensure the safe and hygienic transport of food products and ingredients. The tubing's resistance to high temperatures and chemicals makes it suitable for use in food processing applications, where it is essential to maintain the quality and safety of the products being handled. It is used in various applications, including beverage dispensing systems, dairy processing, and food packaging, where it is crucial to prevent contamination and ensure the integrity of the final product. The tubing's smooth surface and non-stick properties also make it easy to clean and maintain, reducing the risk of bacterial growth and ensuring compliance with stringent food safety regulations. Overall, the Global PFA High Purity Tubing Market plays a vital role in ensuring the safety, efficiency, and reliability of critical processes across these industries, driven by the need for high-performance materials that can withstand the challenges of modern industrial environments.

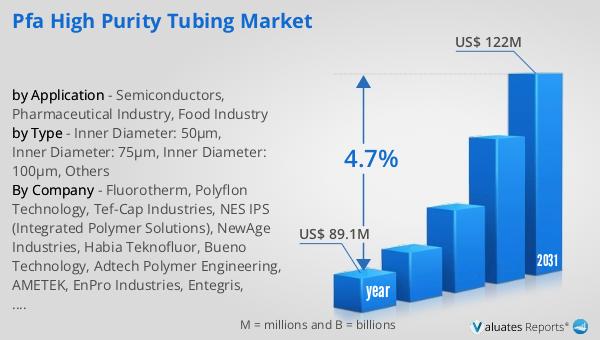

Global PFA High Purity Tubing Market Outlook:

The global market for PFA High Purity Tubing was valued at $89.1 million in 2024, and it is anticipated to grow to a revised size of $122 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.7% during the forecast period. This growth trajectory underscores the increasing demand for high-performance materials that can meet the stringent requirements of industries such as semiconductors, pharmaceuticals, and food processing. The market's expansion is driven by the need for reliable and durable tubing solutions that can withstand extreme conditions while maintaining purity and integrity. As industries continue to advance technologically, the demand for PFA high purity tubing is expected to rise, driven by the need for materials that ensure the safety and efficiency of critical processes. The market's growth is also supported by the increasing adoption of advanced manufacturing techniques and the development of new applications for PFA high purity tubing. As a result, manufacturers are investing in research and development to enhance the performance and versatility of their products, ensuring that they can meet the evolving needs of their customers. Overall, the Global PFA High Purity Tubing Market is poised for significant growth, driven by the increasing demand for high-performance materials that can withstand the challenges of modern industrial environments.

| Report Metric | Details |

| Report Name | PFA High Purity Tubing Market |

| Accounted market size in year | US$ 89.1 million |

| Forecasted market size in 2031 | US$ 122 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fluorotherm, Polyflon Technology, Tef-Cap Industries, NES IPS (Integrated Polymer Solutions), NewAge Industries, Habia Teknofluor, Bueno Technology, Adtech Polymer Engineering, AMETEK, EnPro Industries, Entegris, Grayline, Holscot |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |