What is Global Pipeline Anti-corrosion Coating Market?

The Global Pipeline Anti-corrosion Coating Market is a specialized segment within the broader coatings industry, focusing on the protection of pipelines from corrosion. Corrosion is a natural process that deteriorates metal, leading to potential failures and costly repairs. In the context of pipelines, which are often used to transport oil, gas, water, and other substances, corrosion can lead to leaks, environmental damage, and significant financial losses. Anti-corrosion coatings are applied to the exterior and sometimes the interior of pipelines to prevent this degradation. These coatings act as a barrier, protecting the metal from moisture, chemicals, and other corrosive elements. The market for these coatings is driven by the need for infrastructure maintenance and the expansion of pipeline networks globally. As industries such as oil and gas, water treatment, and agriculture continue to grow, the demand for effective anti-corrosion solutions increases. The market is characterized by a variety of coating technologies, each offering different levels of protection and application methods. Companies in this market are continually innovating to develop more durable, cost-effective, and environmentally friendly coatings to meet the evolving needs of their clients.

Three Layers of Polyethylene, Double Layer Epoxy, Others in the Global Pipeline Anti-corrosion Coating Market:

In the Global Pipeline Anti-corrosion Coating Market, several types of coatings are utilized, each with unique properties and applications. One of the most prominent is the Three Layers of Polyethylene (3LPE) coating. This system consists of three distinct layers: a fusion-bonded epoxy (FBE) base layer, an adhesive middle layer, and a polyethylene top layer. The FBE layer provides excellent adhesion to the steel surface and acts as a primary anti-corrosion barrier. The adhesive layer ensures a strong bond between the FBE and the polyethylene, while the polyethylene layer offers mechanical protection and resistance to environmental factors. This combination makes 3LPE coatings highly effective in protecting pipelines from corrosion, especially in harsh environments. Another widely used coating is the Double Layer Epoxy (DLE) system. This involves the application of two layers of epoxy resin, which provides a robust barrier against moisture and chemicals. Epoxy coatings are known for their excellent adhesion, chemical resistance, and durability, making them suitable for pipelines exposed to aggressive substances. The DLE system is often chosen for its cost-effectiveness and ease of application, particularly in regions where environmental conditions are less severe. In addition to these, there are other types of coatings used in the market, such as coal tar enamel, polyurethane, and polypropylene coatings. Coal tar enamel has been used for decades due to its excellent water resistance and low cost, although environmental concerns have led to a decline in its usage. Polyurethane coatings offer flexibility and abrasion resistance, making them suitable for pipelines that experience movement or vibration. Polypropylene coatings, similar to polyethylene, provide excellent mechanical protection and are often used in conjunction with other coating systems for enhanced performance. Each of these coatings has its advantages and limitations, and the choice of coating depends on factors such as the pipeline's location, the substances being transported, and the environmental conditions. Companies in the Global Pipeline Anti-corrosion Coating Market are continually researching and developing new formulations to improve the performance and sustainability of these coatings. Innovations such as nanotechnology and environmentally friendly materials are being explored to create coatings that offer superior protection while minimizing environmental impact. As the demand for reliable and durable pipeline infrastructure grows, the importance of selecting the right anti-corrosion coating becomes increasingly critical.

Oil and Gas Pipelines, Agricultural Transport System, Others in the Global Pipeline Anti-corrosion Coating Market:

The usage of Global Pipeline Anti-corrosion Coating Market products spans several key areas, including oil and gas pipelines, agricultural transport systems, and other applications. In the oil and gas industry, pipelines are essential for transporting crude oil, natural gas, and refined products over long distances. These pipelines often traverse challenging terrains and are exposed to harsh environmental conditions, making them susceptible to corrosion. Anti-corrosion coatings play a vital role in ensuring the integrity and longevity of these pipelines. By providing a protective barrier against moisture, chemicals, and other corrosive elements, these coatings help prevent leaks and spills, which can have catastrophic environmental and financial consequences. In agricultural transport systems, pipelines are used to convey water, fertilizers, and other agricultural inputs. These pipelines are often exposed to soil, water, and varying weather conditions, all of which can contribute to corrosion. Anti-corrosion coatings help protect these pipelines, ensuring the efficient and reliable delivery of essential resources to farms and agricultural operations. By preventing corrosion, these coatings help reduce maintenance costs and extend the lifespan of the infrastructure, contributing to the overall sustainability of agricultural practices. Beyond oil and gas and agriculture, anti-corrosion coatings are used in various other applications, such as water treatment facilities, chemical processing plants, and infrastructure projects. In water treatment facilities, pipelines are used to transport treated and untreated water, and corrosion can lead to contamination and system failures. Anti-corrosion coatings help maintain the quality and safety of the water supply by preventing leaks and ensuring the structural integrity of the pipelines. In chemical processing plants, pipelines are exposed to aggressive chemicals and high temperatures, making them particularly vulnerable to corrosion. Specialized anti-corrosion coatings are used to protect these pipelines, ensuring safe and efficient operations. Infrastructure projects, such as bridges and tunnels, also benefit from anti-corrosion coatings, which help protect steel structures from the damaging effects of moisture and pollutants. Overall, the Global Pipeline Anti-corrosion Coating Market plays a crucial role in maintaining the safety, efficiency, and sustainability of various industries by providing essential protection against corrosion.

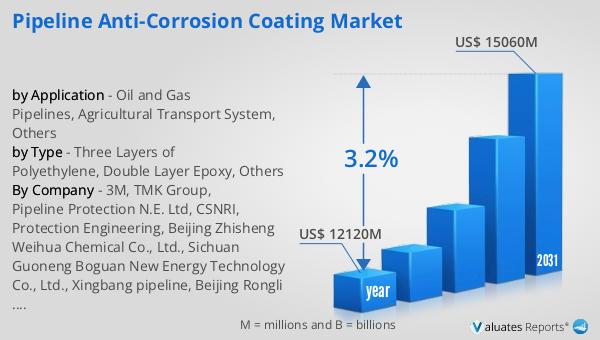

Global Pipeline Anti-corrosion Coating Market Outlook:

The outlook for the Global Pipeline Anti-corrosion Coating Market indicates a positive growth trajectory. In 2024, the market was valued at approximately US$ 12,120 million, and it is anticipated to expand to a revised size of US$ 15,060 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.2% over the forecast period. A significant factor contributing to this growth is the increasing demand for pipeline infrastructure across various industries, including oil and gas, agriculture, and water treatment. As these industries expand, the need for reliable and durable pipeline systems becomes more critical, driving the demand for effective anti-corrosion coatings. Additionally, the market is characterized by a high level of competition, with the top five manufacturers holding a collective market share of over 40%. These leading companies are continually investing in research and development to innovate and improve their product offerings. By focusing on developing more advanced, cost-effective, and environmentally friendly coatings, these manufacturers aim to meet the evolving needs of their customers and maintain their competitive edge in the market. The ongoing advancements in coating technologies, coupled with the growing awareness of the importance of corrosion protection, are expected to further propel the market's growth in the coming years.

| Report Metric | Details |

| Report Name | Pipeline Anti-corrosion Coating Market |

| Accounted market size in year | US$ 12120 million |

| Forecasted market size in 2031 | US$ 15060 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3M, TMK Group, Pipeline Protection N.E. Ltd, CSNRI, Protection Engineering, Beijing Zhisheng Weihua Chemical Co., Ltd., Sichuan Guoneng Boguan New Energy Technology Co., Ltd., Xingbang pipeline, Beijing Rongli Hengye Technology Co., Ltd., Hilong Holding Limited, Mannesmann, Langfang Zhuoya Anticorrosion Equipment Co., Ltd., Zibo Qicheng Resin Co., Ltd., Cangzhou Xinlong Pipeline Anticorrosion |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |