What is Global Plastic Prototyping Service Market?

The Global Plastic Prototyping Service Market is a dynamic and rapidly evolving sector that plays a crucial role in the development and innovation of various industries. This market involves the creation of plastic prototypes, which are essentially preliminary versions of products made from plastic materials. These prototypes are used to test and refine designs before mass production, ensuring that the final product meets the desired specifications and quality standards. The market is driven by the increasing demand for rapid prototyping solutions, which allow companies to quickly and cost-effectively develop and test new products. With advancements in technology, the plastic prototyping service market has expanded to include a variety of methods such as 3D printing, CNC machining, vacuum casting, and injection molding. These methods offer different advantages in terms of speed, precision, and material properties, catering to the diverse needs of industries ranging from automotive to electronics. As businesses continue to seek innovative ways to reduce time-to-market and improve product quality, the global plastic prototyping service market is expected to grow, offering new opportunities for service providers and manufacturers alike.

Vacuum Casting, 3D Printing, CNC Machining, Injection Molding in the Global Plastic Prototyping Service Market:

Vacuum casting, 3D printing, CNC machining, and injection molding are pivotal processes within the Global Plastic Prototyping Service Market, each offering unique benefits and applications. Vacuum casting is a process that involves creating silicone molds to produce high-quality plastic prototypes. This method is particularly advantageous for producing small batches of prototypes with intricate details and smooth surface finishes. It is often used when the prototype needs to closely resemble the final product in terms of appearance and material properties. Vacuum casting is cost-effective for low-volume production and is ideal for testing product designs before committing to more expensive production methods. On the other hand, 3D printing, also known as additive manufacturing, has revolutionized the prototyping landscape by enabling the creation of complex geometries that were previously impossible or too costly to produce. This method builds prototypes layer by layer, allowing for rapid iteration and customization. 3D printing is highly versatile and can use a wide range of materials, making it suitable for various applications across different industries. It is particularly beneficial for creating functional prototypes and parts with intricate designs. CNC machining, which stands for Computer Numerical Control machining, is a subtractive manufacturing process that involves removing material from a solid block to create a prototype. This method is known for its precision and ability to produce high-quality prototypes with tight tolerances. CNC machining is ideal for creating prototypes that require specific mechanical properties and is often used in industries where precision is critical, such as aerospace and automotive. Lastly, injection molding is a process used for producing large quantities of plastic parts by injecting molten plastic into a mold. While traditionally used for mass production, injection molding is also employed in prototyping to create samples that closely mimic the final product. This method is beneficial for testing the manufacturability of a design and is often used when the prototype needs to be tested under real-world conditions. Each of these methods plays a vital role in the plastic prototyping service market, offering different advantages that cater to the specific needs of various industries. As technology continues to advance, these methods are becoming more efficient and accessible, driving further growth in the market.

Automotive Industry, Chemical Industry, Electronic Industry, Others in the Global Plastic Prototyping Service Market:

The Global Plastic Prototyping Service Market finds extensive usage across various industries, including the automotive, chemical, and electronic sectors, among others. In the automotive industry, plastic prototyping services are crucial for developing new vehicle components and systems. Prototypes allow automotive manufacturers to test and refine designs for parts such as dashboards, bumpers, and interior components before committing to full-scale production. This not only helps in identifying potential design flaws but also aids in optimizing the performance and aesthetics of the final product. The ability to quickly produce and test prototypes is essential in the highly competitive automotive market, where innovation and speed-to-market are key drivers of success. In the chemical industry, plastic prototyping services are used to develop and test new packaging solutions and chemical processing equipment. Prototypes help in evaluating the compatibility of materials with various chemicals and ensure that the final product meets safety and regulatory standards. This is particularly important in the chemical industry, where the integrity of packaging and equipment is critical to preventing leaks and ensuring safe handling of hazardous materials. The electronic industry also heavily relies on plastic prototyping services for the development of new devices and components. Prototypes are used to test the fit, form, and function of electronic enclosures, connectors, and other components. This helps manufacturers ensure that their products meet the required specifications and perform reliably in real-world conditions. Additionally, the ability to quickly iterate and refine designs is crucial in the fast-paced electronics market, where product lifecycles are short and consumer demands are constantly evolving. Beyond these industries, plastic prototyping services are used in a wide range of other applications, including consumer goods, medical devices, and industrial equipment. In each of these areas, the ability to rapidly develop and test prototypes is essential for driving innovation and ensuring the success of new products. As the demand for customized and high-quality products continues to grow, the global plastic prototyping service market is expected to play an increasingly important role in supporting the development and commercialization of new technologies and solutions.

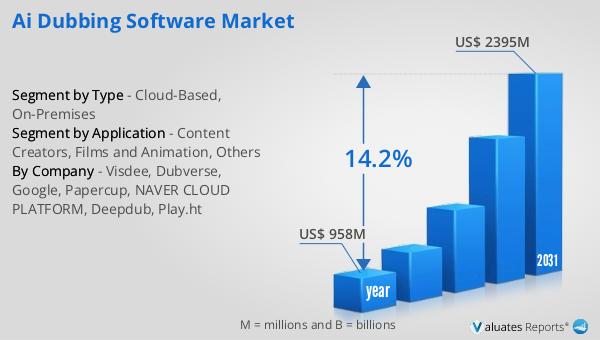

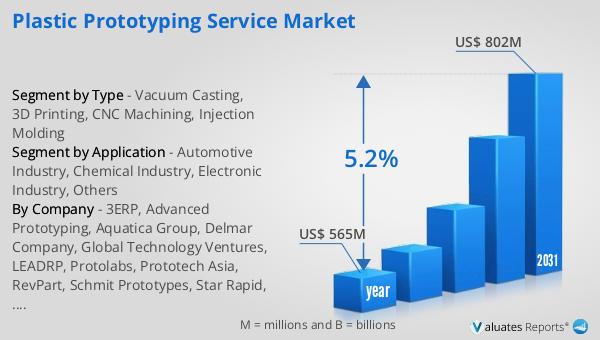

Global Plastic Prototyping Service Market Outlook:

The global market for Plastic Prototyping Service was valued at $565 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $802 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.2% over the forecast period. This upward trend highlights the increasing demand for plastic prototyping services across various industries, driven by the need for rapid and cost-effective product development solutions. As companies strive to reduce time-to-market and enhance product quality, the adoption of advanced prototyping technologies is expected to rise. The market's expansion is also fueled by technological advancements that have made prototyping processes more efficient and accessible. With the continuous evolution of methods such as 3D printing, CNC machining, vacuum casting, and injection molding, businesses are better equipped to meet the diverse needs of their customers. This growth not only presents opportunities for service providers and manufacturers but also underscores the importance of innovation in maintaining a competitive edge in the market. As the global economy continues to evolve, the plastic prototyping service market is poised to play a pivotal role in shaping the future of product development and manufacturing.

| Report Metric | Details |

| Report Name | Plastic Prototyping Service Market |

| Accounted market size in year | US$ 565 million |

| Forecasted market size in 2031 | US$ 802 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | 3ERP, Advanced Prototyping, Aquatica Group, Delmar Company, Global Technology Ventures, LEADRP, Protolabs, Prototech Asia, RevPart, Schmit Prototypes, Star Rapid, Xometry |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |