What is Global Metal Insert Molding Service Market?

The Global Metal Insert Molding Service Market is a specialized sector within the broader manufacturing industry that focuses on the integration of metal components into plastic parts through a process known as insert molding. This technique involves placing metal inserts into a mold cavity, after which molten plastic is injected, encapsulating the metal insert to form a single, cohesive part. This process is highly valued for its ability to enhance the mechanical properties of plastic components, such as strength, conductivity, and durability, while also allowing for complex geometries and reduced assembly times. The market for metal insert molding services is driven by the increasing demand for lightweight and high-performance materials across various industries, including automotive, electronics, medical, and consumer goods. As manufacturers seek to improve product performance and reduce costs, the adoption of metal insert molding is expected to grow, offering a competitive advantage through improved product quality and efficiency. The market is characterized by a diverse range of service providers, from small specialized firms to large multinational corporations, each offering unique capabilities and expertise in metal insert molding technologies.

Manual Insert Molding Service, Automatic Insert Molding Service in the Global Metal Insert Molding Service Market:

Manual Insert Molding Service and Automatic Insert Molding Service are two primary methods utilized within the Global Metal Insert Molding Service Market, each offering distinct advantages and applications. Manual Insert Molding Service involves the manual placement of metal inserts into the mold cavity before the plastic injection process. This method is typically employed for low to medium volume production runs or when dealing with complex or delicate inserts that require precise handling. The manual approach allows for greater flexibility and customization, as operators can adjust the placement of inserts to accommodate specific design requirements. However, it is labor-intensive and may result in longer cycle times compared to automated processes. On the other hand, Automatic Insert Molding Service utilizes automated machinery to place metal inserts into the mold cavity, significantly reducing the need for human intervention. This method is ideal for high-volume production runs, where consistency, speed, and efficiency are paramount. Automated systems can handle a wide range of insert sizes and shapes, ensuring precise placement and alignment within the mold. The use of robotics and advanced automation technologies in automatic insert molding enhances production throughput and reduces the risk of human error, leading to improved product quality and reduced manufacturing costs. Both manual and automatic insert molding services play a crucial role in the global market, catering to diverse industry needs and production scales. Manufacturers often choose between these methods based on factors such as production volume, complexity of the insert, and cost considerations. As technology continues to advance, the integration of smart manufacturing solutions and Industry 4.0 principles is expected to further enhance the capabilities and efficiency of both manual and automatic insert molding services, driving innovation and growth within the Global Metal Insert Molding Service Market.

Automotive Industry, Medical Industry, Electrical Industry, Consumer Goods Industry in the Global Metal Insert Molding Service Market:

The Global Metal Insert Molding Service Market finds extensive application across various industries, each leveraging the unique benefits of insert molding to enhance product performance and functionality. In the Automotive Industry, metal insert molding is used to produce lightweight yet durable components that contribute to vehicle efficiency and safety. Applications include engine components, interior and exterior trim, and electrical connectors, where the integration of metal inserts provides enhanced strength, thermal stability, and electrical conductivity. The Medical Industry benefits from metal insert molding through the production of medical devices and equipment that require precise and reliable performance. Metal inserts are used to reinforce plastic parts, ensuring durability and resistance to wear and tear in critical applications such as surgical instruments, diagnostic equipment, and implantable devices. In the Electrical Industry, metal insert molding is employed to manufacture components that require electrical conductivity and thermal management, such as connectors, switches, and housings for electronic devices. The process allows for the integration of metal inserts that provide the necessary conductive pathways while maintaining the lightweight and insulating properties of plastic. The Consumer Goods Industry utilizes metal insert molding to produce a wide range of products, from household appliances to personal electronics, where the combination of metal and plastic enhances product aesthetics, functionality, and durability. The ability to create complex shapes and integrate multiple functions into a single part makes metal insert molding an attractive solution for consumer goods manufacturers seeking to differentiate their products in a competitive market. Overall, the versatility and efficiency of metal insert molding make it a valuable tool for industries seeking to innovate and improve their product offerings.

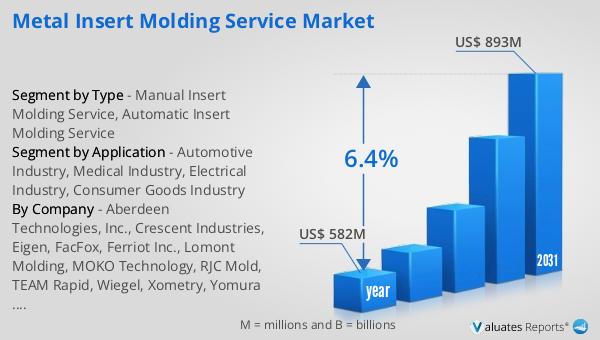

Global Metal Insert Molding Service Market Outlook:

The outlook for the Global Metal Insert Molding Service Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 582 million, reflecting the increasing demand for advanced manufacturing solutions that combine metal and plastic components. By 2031, the market is projected to reach a revised size of US$ 893 million, driven by a compound annual growth rate (CAGR) of 6.4% during the forecast period. This growth trajectory underscores the expanding adoption of metal insert molding across various industries, as manufacturers seek to enhance product performance, reduce costs, and improve production efficiency. The market's expansion is supported by advancements in automation and smart manufacturing technologies, which are expected to further optimize the insert molding process and enable the production of more complex and high-performance components. As industries continue to evolve and demand more sophisticated solutions, the Global Metal Insert Molding Service Market is poised to play a critical role in meeting these needs, offering innovative and cost-effective manufacturing options that align with the latest industry trends and requirements.

| Report Metric | Details |

| Report Name | Metal Insert Molding Service Market |

| Accounted market size in year | US$ 582 million |

| Forecasted market size in 2031 | US$ 893 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Aberdeen Technologies, Inc., Crescent Industries, Eigen, FacFox, Ferriot Inc., Lomont Molding, MOKO Technology, RJC Mold, TEAM Rapid, Wiegel, Xometry, Yomura Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |