What is Global Factory Acceptance Testing Market?

The Global Factory Acceptance Testing (FAT) Market is a crucial segment in the industrial and manufacturing sectors, focusing on ensuring that equipment and systems meet specified requirements before they are shipped to the customer. This process involves a series of tests and inspections conducted at the manufacturer's site to verify that the equipment functions correctly and adheres to the agreed-upon specifications. FAT is an essential step in quality assurance, providing both the manufacturer and the customer with confidence that the equipment will perform as expected once installed. It helps in identifying any potential issues or defects early in the production process, thereby reducing the risk of costly modifications or repairs after delivery. The market for FAT is driven by the increasing demand for high-quality, reliable equipment across various industries, including energy, utilities, and transportation. As industries continue to evolve and adopt more complex technologies, the need for thorough testing and validation processes like FAT becomes even more critical. This market is characterized by a growing emphasis on compliance with international standards and regulations, which further underscores the importance of factory acceptance testing in ensuring product quality and safety.

Contract Acceptance Testing, Regulation Acceptance Testing, Operational Acceptance Testing in the Global Factory Acceptance Testing Market:

Contract Acceptance Testing, Regulation Acceptance Testing, and Operational Acceptance Testing are integral components of the Global Factory Acceptance Testing Market, each serving distinct purposes in the validation process. Contract Acceptance Testing focuses on ensuring that the equipment or system meets the specific terms and conditions outlined in the contract between the manufacturer and the customer. This type of testing verifies that all contractual obligations, such as performance criteria, design specifications, and delivery timelines, are met. It is a critical step in the FAT process, as it provides assurance to both parties that the product aligns with the agreed-upon requirements, thereby minimizing the risk of disputes or dissatisfaction post-delivery. Regulation Acceptance Testing, on the other hand, is centered around compliance with industry standards and regulatory requirements. This testing ensures that the equipment adheres to the necessary safety, environmental, and operational standards set by governing bodies. Compliance with these regulations is crucial for manufacturers to avoid legal penalties and to ensure the safe and efficient operation of their products. Regulation Acceptance Testing often involves rigorous inspections and documentation to verify that all regulatory criteria are satisfied. Operational Acceptance Testing is the final phase in the FAT process, focusing on the practical functionality and performance of the equipment in a simulated operational environment. This testing assesses whether the equipment can perform its intended functions under real-world conditions, ensuring that it is ready for deployment and use. Operational Acceptance Testing is vital for identifying any potential issues that may arise during actual operation, allowing manufacturers to address them before the equipment is delivered to the customer. Together, these three types of acceptance testing form a comprehensive framework for ensuring product quality, compliance, and performance in the Global Factory Acceptance Testing Market. They provide a structured approach to validating equipment and systems, thereby enhancing customer satisfaction and trust in the manufacturer's products. As industries continue to demand higher standards of quality and reliability, the importance of these acceptance testing processes in the FAT market is expected to grow, driving innovation and improvement in testing methodologies and technologies.

Energy and Electricity, Equipment Manufacturing, Utilities, Transportation, Others in the Global Factory Acceptance Testing Market:

The Global Factory Acceptance Testing Market plays a significant role in various industries, including energy and electricity, equipment manufacturing, utilities, transportation, and others. In the energy and electricity sector, FAT is crucial for ensuring that power generation and distribution equipment meet stringent safety and performance standards. This includes testing transformers, switchgear, and other critical components to verify their reliability and efficiency. By conducting thorough factory acceptance tests, manufacturers can identify and rectify any potential issues before the equipment is deployed, thereby minimizing the risk of failures and ensuring a stable power supply. In equipment manufacturing, FAT is essential for validating the quality and functionality of machinery and equipment used in various industrial applications. This includes testing mechanical, electrical, and electronic components to ensure they meet the required specifications and performance criteria. By conducting comprehensive acceptance tests, manufacturers can enhance the reliability and durability of their products, thereby increasing customer satisfaction and reducing warranty claims. In the utilities sector, FAT is used to verify the performance and compliance of equipment used in water, gas, and other utility services. This includes testing pumps, valves, meters, and other critical components to ensure they meet the necessary regulatory and operational standards. By conducting rigorous factory acceptance tests, manufacturers can ensure the safe and efficient operation of utility equipment, thereby enhancing service reliability and customer satisfaction. In the transportation industry, FAT is used to validate the performance and safety of vehicles, components, and systems used in various modes of transport, including automotive, aerospace, and rail. This includes testing engines, brakes, control systems, and other critical components to ensure they meet the required safety and performance standards. By conducting thorough acceptance tests, manufacturers can enhance the safety and reliability of their products, thereby reducing the risk of accidents and improving customer confidence. In other industries, FAT is used to validate the quality and performance of a wide range of equipment and systems, including medical devices, consumer electronics, and industrial machinery. By conducting comprehensive factory acceptance tests, manufacturers can ensure their products meet the required specifications and performance criteria, thereby enhancing customer satisfaction and reducing the risk of product recalls. Overall, the Global Factory Acceptance Testing Market plays a vital role in ensuring the quality, safety, and reliability of equipment and systems across various industries, thereby driving innovation and improvement in testing methodologies and technologies.

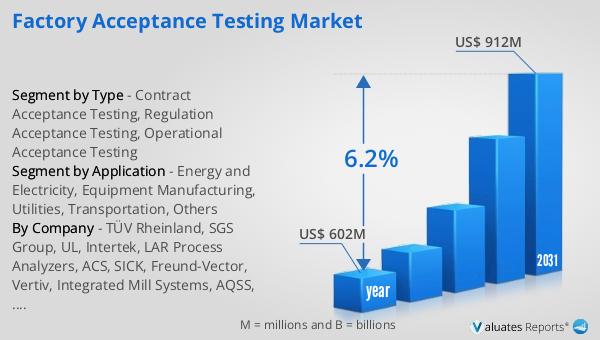

Global Factory Acceptance Testing Market Outlook:

The global market for Factory Acceptance Testing was valued at $602 million in 2024 and is anticipated to expand to a revised size of $912 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.2% over the forecast period. This growth trajectory underscores the increasing importance of factory acceptance testing in ensuring the quality and reliability of industrial equipment and systems. As industries continue to evolve and adopt more complex technologies, the demand for thorough testing and validation processes like FAT is expected to rise. This market growth is driven by several factors, including the increasing emphasis on compliance with international standards and regulations, the need for high-quality, reliable equipment across various industries, and the growing complexity of industrial systems and technologies. The expansion of the FAT market is also supported by advancements in testing methodologies and technologies, which enable more efficient and accurate testing processes. As a result, manufacturers are increasingly investing in factory acceptance testing to enhance the quality and reliability of their products, thereby improving customer satisfaction and reducing the risk of costly modifications or repairs after delivery. Overall, the projected growth of the Global Factory Acceptance Testing Market highlights the critical role of FAT in ensuring product quality and safety in an increasingly complex and competitive industrial landscape.

| Report Metric | Details |

| Report Name | Factory Acceptance Testing Market |

| Accounted market size in year | US$ 602 million |

| Forecasted market size in 2031 | US$ 912 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | TÜV Rheinland, SGS Group, UL, Intertek, LAR Process Analyzers, ACS, SICK, Freund-Vector, Vertiv, Integrated Mill Systems, AQSS, Mangan Power, PCX Corp |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |