What is Global Paperless Bushings Market?

The Global Paperless Bushings Market is a specialized segment within the broader electrical components industry, focusing on bushings that do not use traditional paper insulation. These bushings are essential components in electrical systems, serving as insulators and providing a path for electrical conductors to pass through grounded barriers safely. The market for paperless bushings is driven by the demand for more efficient, reliable, and environmentally friendly electrical components. As industries worldwide strive to reduce their carbon footprint and enhance the efficiency of their electrical systems, the adoption of paperless bushings is becoming increasingly popular. These bushings are typically used in high-voltage applications, where their superior performance characteristics, such as better thermal stability and reduced risk of failure, are highly valued. The market is characterized by continuous innovation, with manufacturers investing in research and development to improve the materials and technologies used in these bushings. This focus on innovation is crucial as it helps meet the evolving needs of industries such as power generation, transmission, and distribution. Overall, the Global Paperless Bushings Market is poised for growth as it aligns with global trends towards sustainability and efficiency in electrical infrastructure.

Resin Impregnated Fibre Bushings, Resin Impregnated Synthetic Bushings in the Global Paperless Bushings Market:

Resin Impregnated Fibre Bushings and Resin Impregnated Synthetic Bushings are two prominent types of bushings within the Global Paperless Bushings Market. Resin Impregnated Fibre Bushings are made by impregnating a fibrous material with resin, which enhances their mechanical strength and electrical insulation properties. These bushings are known for their durability and ability to withstand high temperatures, making them suitable for use in demanding electrical applications. The resin impregnation process ensures that the fibres are thoroughly coated, providing a uniform and reliable insulating layer. This type of bushing is particularly advantageous in environments where thermal stability and resistance to moisture are critical. On the other hand, Resin Impregnated Synthetic Bushings are made using synthetic materials, which are also impregnated with resin to enhance their performance characteristics. These bushings offer similar benefits to their fibre counterparts, such as improved mechanical strength and electrical insulation. However, synthetic bushings often provide additional advantages, such as lighter weight and greater flexibility in design. The use of synthetic materials allows for more precise engineering of the bushing's properties, enabling manufacturers to tailor them to specific applications. Both types of bushings are integral to the Global Paperless Bushings Market, as they offer solutions to the challenges faced by traditional paper-insulated bushings. The shift towards resin-impregnated bushings is driven by the need for more reliable and efficient electrical components that can operate under increasingly demanding conditions. As industries continue to evolve and require more advanced electrical systems, the demand for these innovative bushing solutions is expected to grow. Manufacturers are continually exploring new materials and technologies to enhance the performance of resin-impregnated bushings, ensuring they meet the stringent requirements of modern electrical applications. This ongoing innovation is a testament to the dynamic nature of the Global Paperless Bushings Market and its commitment to providing cutting-edge solutions for the electrical industry.

Power Transformer, Switching Equipment, Generator, Others in the Global Paperless Bushings Market:

The Global Paperless Bushings Market finds its applications in various areas, including Power Transformers, Switching Equipment, Generators, and other electrical systems. In Power Transformers, paperless bushings play a crucial role in ensuring the safe and efficient transmission of electrical energy. These bushings provide the necessary insulation and mechanical support for the conductors passing through the transformer, preventing electrical faults and enhancing the overall reliability of the system. The use of paperless bushings in power transformers is particularly beneficial due to their superior thermal stability and resistance to environmental factors, which are essential for maintaining the performance of transformers over long periods. In Switching Equipment, paperless bushings are used to insulate and support the electrical conductors within the switchgear. This application requires bushings that can withstand high voltages and provide reliable insulation to prevent electrical arcing and short circuits. The advanced materials used in paperless bushings offer excellent dielectric properties, making them ideal for use in switching equipment where safety and reliability are paramount. Generators also benefit from the use of paperless bushings, as they provide the necessary insulation for the electrical conductors within the generator. This insulation is critical for preventing electrical faults and ensuring the efficient operation of the generator. The durability and thermal stability of paperless bushings make them well-suited for use in generators, where they must withstand the high temperatures and mechanical stresses associated with power generation. In addition to these applications, paperless bushings are used in various other electrical systems, where their superior performance characteristics are highly valued. The versatility and reliability of paperless bushings make them an attractive option for a wide range of electrical applications, contributing to the growth of the Global Paperless Bushings Market. As industries continue to demand more efficient and reliable electrical components, the use of paperless bushings is expected to expand, further driving the market's growth.

Global Paperless Bushings Market Outlook:

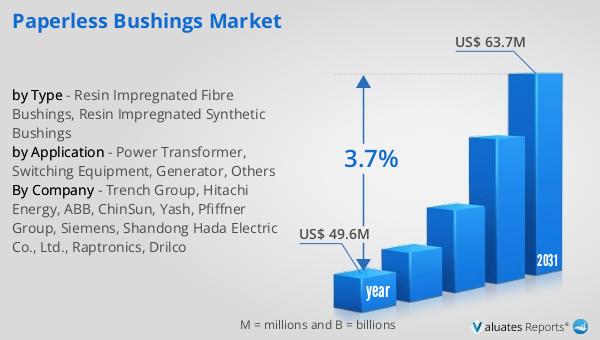

The outlook for the Global Paperless Bushings Market indicates a promising future, with the market valued at approximately US$ 49.6 million in 2024. It is anticipated to grow steadily, reaching an estimated size of US$ 63.7 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.7% over the forecast period. The increasing demand for efficient and reliable electrical components is a key driver of this market growth. As industries worldwide continue to modernize their electrical infrastructure, the need for advanced bushing solutions that offer superior performance and environmental benefits is becoming more pronounced. The shift towards paperless bushings is also influenced by the growing emphasis on sustainability and the reduction of carbon footprints in industrial operations. Manufacturers in the market are focusing on innovation and the development of new materials and technologies to meet the evolving needs of their customers. This commitment to innovation is crucial for maintaining competitiveness in the market and ensuring the continued growth of the Global Paperless Bushings Market. As the market expands, it is expected to create new opportunities for manufacturers and suppliers, further driving the adoption of paperless bushings in various industries.

| Report Metric | Details |

| Report Name | Paperless Bushings Market |

| Accounted market size in year | US$ 49.6 million |

| Forecasted market size in 2031 | US$ 63.7 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Trench Group, Hitachi Energy, ABB, ChinSun, Yash, Pfiffner Group, Siemens, Shandong Hada Electric Co., Ltd., Raptronics, Drilco |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |