What is Global Insert Molding Service Market?

The Global Insert Molding Service Market is a specialized segment within the manufacturing industry that focuses on the integration of different materials into a single molded part. This process involves placing an insert, which can be made of metal, plastic, or other materials, into a mold cavity and then injecting molten material around it to form a single, cohesive unit. The primary advantage of insert molding is its ability to combine multiple components into a single part, reducing assembly time and improving product strength and reliability. This market is driven by the increasing demand for lightweight and durable components in various industries, including automotive, electronics, and consumer goods. As manufacturers seek to enhance product performance and reduce costs, the adoption of insert molding services is expected to grow. The market is characterized by technological advancements, such as the development of new materials and improved molding techniques, which enhance the efficiency and quality of the final products. Additionally, the growing emphasis on sustainability and the use of eco-friendly materials is influencing the market dynamics, as companies strive to meet environmental regulations and consumer preferences. Overall, the Global Insert Molding Service Market plays a crucial role in modern manufacturing, offering innovative solutions for complex product designs.

Plastic, Metal in the Global Insert Molding Service Market:

In the realm of the Global Insert Molding Service Market, plastic and metal are two pivotal materials that significantly influence the manufacturing landscape. Plastic, known for its versatility and lightweight properties, is extensively used in insert molding to create components that are not only durable but also cost-effective. The adaptability of plastic allows it to be molded into intricate shapes, making it ideal for applications in consumer electronics, automotive parts, and home appliances. Its ability to withstand various environmental conditions without degrading makes it a preferred choice for manufacturers aiming to produce high-quality products with a longer lifespan. Moreover, advancements in plastic materials, such as the development of high-performance polymers, have expanded the possibilities for insert molding, enabling the production of parts that can endure extreme temperatures and mechanical stress. On the other hand, metal inserts are integral to the insert molding process, providing structural integrity and enhancing the mechanical properties of the final product. Metals like aluminum, brass, and stainless steel are commonly used due to their strength, conductivity, and resistance to corrosion. The incorporation of metal inserts into plastic components allows manufacturers to achieve a balance between weight and strength, which is particularly beneficial in industries such as automotive and aerospace, where performance and safety are paramount. Metal inserts also facilitate the integration of electrical and thermal conductivity into molded parts, broadening the scope of applications for insert molding services. The synergy between plastic and metal in insert molding is a testament to the innovation within the Global Insert Molding Service Market. By leveraging the unique properties of these materials, manufacturers can produce components that meet the stringent demands of modern industries. The process of insert molding not only enhances the functionality of products but also streamlines production by reducing the need for additional assembly steps. This efficiency translates into cost savings and faster time-to-market, providing a competitive edge for companies that adopt this technology. Furthermore, the environmental impact of using plastic and metal in insert molding is a consideration that is gaining traction in the market. As sustainability becomes a focal point for consumers and regulators alike, manufacturers are exploring eco-friendly alternatives and recycling initiatives to minimize waste and reduce the carbon footprint of their operations. The development of biodegradable plastics and the use of recycled metals are examples of how the industry is adapting to these challenges, ensuring that insert molding remains a viable and responsible manufacturing solution. In conclusion, the interplay between plastic and metal in the Global Insert Molding Service Market underscores the importance of material selection in achieving optimal product performance. As the market continues to evolve, the focus on innovation, efficiency, and sustainability will drive the adoption of insert molding services across various sectors, paving the way for a future where complex, high-quality components are produced with minimal environmental impact.

Home Appliances, Consumer Electronics, Automobile Industry, Others in the Global Insert Molding Service Market:

The Global Insert Molding Service Market finds extensive application across various sectors, including home appliances, consumer electronics, the automobile industry, and others, due to its ability to produce complex, durable, and lightweight components. In the realm of home appliances, insert molding is utilized to manufacture parts that require a combination of materials for enhanced functionality and aesthetics. For instance, components like knobs, handles, and control panels often incorporate metal inserts for added strength and durability, while the outer plastic layer provides a sleek and modern appearance. This integration not only improves the performance of the appliances but also contributes to a seamless design that appeals to consumers. In the consumer electronics sector, the demand for compact and efficient devices has propelled the use of insert molding services. The process is instrumental in creating components that house delicate electronic circuits and connectors, ensuring they are securely encapsulated within a protective plastic shell. This is particularly important for devices such as smartphones, tablets, and wearable technology, where space is limited, and the integrity of the internal components is crucial. Insert molding allows manufacturers to produce parts that are not only robust but also lightweight, enhancing the portability and usability of electronic gadgets. The automobile industry is another significant beneficiary of the Global Insert Molding Service Market. As the industry shifts towards lightweight and fuel-efficient vehicles, the need for components that offer a high strength-to-weight ratio has become paramount. Insert molding enables the production of automotive parts such as dashboards, door panels, and engine components that incorporate metal inserts for structural support while maintaining a lightweight profile. This not only contributes to improved vehicle performance and fuel efficiency but also aligns with the industry's sustainability goals by reducing overall material usage. Beyond these sectors, insert molding services are also employed in various other industries, including medical devices, aerospace, and telecommunications. In the medical field, for example, the process is used to create components that require precise material integration, such as surgical instruments and diagnostic equipment. The ability to combine biocompatible plastics with metal inserts ensures that these products meet stringent safety and performance standards. Similarly, in the aerospace industry, insert molding is used to produce lightweight yet durable components that can withstand the rigors of flight. Overall, the versatility and efficiency of the Global Insert Molding Service Market make it an invaluable asset across multiple industries. By enabling the production of high-quality, multifunctional components, insert molding not only enhances product performance but also supports the broader goals of innovation and sustainability. As industries continue to evolve and demand more sophisticated solutions, the role of insert molding in shaping the future of manufacturing is set to expand further.

Global Insert Molding Service Market Outlook:

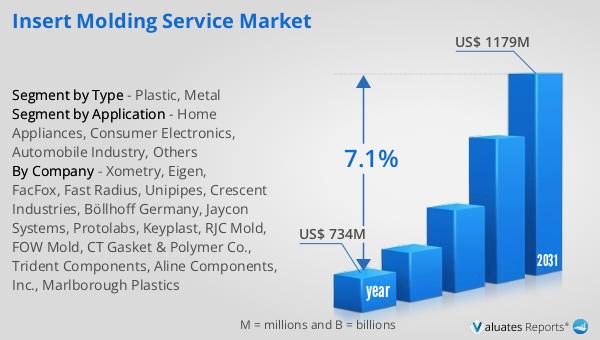

The worldwide market for Insert Molding Service was appraised at $734 million in 2024, and it is anticipated to grow to a revised size of $1,179 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.1% over the forecast period. This growth trajectory underscores the increasing demand for insert molding services across various industries, driven by the need for innovative manufacturing solutions that enhance product performance and reduce costs. The market's expansion is fueled by technological advancements that have improved the efficiency and quality of insert molding processes, enabling manufacturers to produce complex components with greater precision and reliability. As industries such as automotive, electronics, and consumer goods continue to evolve, the demand for lightweight, durable, and multifunctional components is on the rise. Insert molding services offer a viable solution to meet these demands, providing manufacturers with the ability to integrate different materials into a single, cohesive unit. This not only streamlines production but also reduces the need for additional assembly steps, resulting in cost savings and faster time-to-market. Moreover, the growing emphasis on sustainability and the use of eco-friendly materials is influencing the market dynamics, as companies strive to meet environmental regulations and consumer preferences. The development of biodegradable plastics and the use of recycled metals are examples of how the industry is adapting to these challenges, ensuring that insert molding remains a viable and responsible manufacturing solution. In conclusion, the projected growth of the Global Insert Molding Service Market highlights the increasing importance of this technology in modern manufacturing. As companies seek to enhance product performance, reduce costs, and meet sustainability goals, the adoption of insert molding services is expected to continue its upward trajectory, paving the way for a future where complex, high-quality components are produced with minimal environmental impact.

| Report Metric | Details |

| Report Name | Insert Molding Service Market |

| Accounted market size in year | US$ 734 million |

| Forecasted market size in 2031 | US$ 1179 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Xometry, Eigen, FacFox, Fast Radius, Unipipes, Crescent Industries, Böllhoff Germany, Jaycon Systems, Protolabs, Keyplast, RJC Mold, FOW Mold, CT Gasket & Polymer Co., Trident Components, Aline Components, Inc., Marlborough Plastics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |