What is Global 3D Printing Polymer Material for Medical Market?

The Global 3D Printing Polymer Material for Medical Market is a rapidly evolving sector that leverages advanced technology to revolutionize the medical field. This market focuses on the use of 3D printing technology to create polymer-based materials specifically designed for medical applications. These materials are used to produce a wide range of medical devices and components, from prosthetics and implants to surgical instruments and dental products. The primary advantage of using 3D printing in the medical field is its ability to produce highly customized and complex structures that are tailored to individual patient needs. This customization enhances the effectiveness and comfort of medical devices, leading to improved patient outcomes. Additionally, 3D printing reduces waste and production time, making it a cost-effective solution for healthcare providers. The market is driven by continuous advancements in 3D printing technology, increasing demand for personalized medical solutions, and the growing adoption of polymer materials due to their versatility and biocompatibility. As the healthcare industry continues to embrace innovation, the Global 3D Printing Polymer Material for Medical Market is poised for significant growth, offering new possibilities for patient care and treatment.

Polyether Ether Ketone (PEEK), Polymethylmethacrylate (PMMA), Polylactic Acid (PLA), Others in the Global 3D Printing Polymer Material for Medical Market:

Polyether Ether Ketone (PEEK), Polymethylmethacrylate (PMMA), Polylactic Acid (PLA), and other polymers play a crucial role in the Global 3D Printing Polymer Material for Medical Market. PEEK is a high-performance thermoplastic known for its exceptional mechanical properties, chemical resistance, and biocompatibility. It is widely used in medical applications such as spinal implants, dental implants, and orthopedic devices due to its ability to withstand sterilization processes and its compatibility with the human body. PEEK's strength and durability make it an ideal choice for load-bearing applications, providing long-lasting solutions for patients. Polymethylmethacrylate (PMMA), commonly known as acrylic, is another important polymer in the medical field. It is valued for its transparency, biocompatibility, and ease of processing. PMMA is often used in the production of intraocular lenses, bone cement, and cranial implants. Its optical clarity makes it suitable for applications where visibility is crucial, such as in ophthalmology. Polylactic Acid (PLA) is a biodegradable polymer derived from renewable resources like corn starch or sugarcane. It is gaining popularity in the medical sector due to its eco-friendly nature and biocompatibility. PLA is commonly used in the production of surgical sutures, tissue engineering scaffolds, and drug delivery systems. Its biodegradability allows for temporary medical applications where the material can safely degrade within the body over time. Other polymers used in the 3D printing of medical devices include polycaprolactone (PCL), polyvinyl alcohol (PVA), and thermoplastic polyurethane (TPU). These materials offer unique properties that cater to specific medical needs. For instance, PCL is known for its slow degradation rate, making it suitable for long-term implants, while PVA is used for its water solubility in applications like support structures during the printing process. TPU, on the other hand, is valued for its flexibility and elasticity, making it ideal for applications requiring soft and flexible materials, such as prosthetic liners and wearable medical devices. The choice of polymer material in 3D printing for medical applications depends on various factors, including the intended use, required mechanical properties, biocompatibility, and regulatory considerations. Each polymer offers distinct advantages that can be leveraged to create innovative and effective medical solutions. As research and development in polymer science continue to advance, new materials with enhanced properties are expected to emerge, further expanding the possibilities for 3D printing in the medical field. The integration of these polymers into 3D printing technology is transforming the way medical devices are designed and manufactured, offering unprecedented levels of customization and precision. This transformation is not only improving patient care but also driving the growth of the Global 3D Printing Polymer Material for Medical Market.

Dental, Hearing Aids, Others in the Global 3D Printing Polymer Material for Medical Market:

The usage of Global 3D Printing Polymer Material for Medical Market extends to various areas, including dental applications, hearing aids, and other medical fields. In the dental industry, 3D printing has revolutionized the way dental products are manufactured. Dental professionals can now create highly accurate and customized dental implants, crowns, bridges, and orthodontic devices using 3D printing technology. The use of polymers such as PEEK and PMMA in dental applications ensures that the products are biocompatible, durable, and aesthetically pleasing. 3D printing allows for precise control over the design and fit of dental products, resulting in improved patient comfort and satisfaction. Additionally, the ability to produce dental products on-demand reduces lead times and costs, making dental care more accessible to patients. In the field of hearing aids, 3D printing has enabled the production of custom-fit devices that perfectly match the unique contours of a patient's ear. This customization enhances the comfort and effectiveness of hearing aids, leading to better hearing outcomes for users. Polymers like TPU are often used in the production of hearing aids due to their flexibility and comfort. The use of 3D printing in this area also allows for rapid prototyping and production, enabling manufacturers to quickly respond to changes in demand and patient needs. Beyond dental and hearing aid applications, 3D printing polymer materials are used in a wide range of other medical fields. For instance, in orthopedics, 3D printing is used to create custom prosthetics and orthotic devices that are tailored to the specific needs of patients. The use of polymers like PEEK and PLA in these applications ensures that the devices are lightweight, durable, and biocompatible. In the field of surgery, 3D printing is used to produce surgical instruments and models that aid in pre-surgical planning and training. These models provide surgeons with a detailed and accurate representation of a patient's anatomy, allowing for more precise and effective surgical procedures. The versatility of 3D printing polymer materials also extends to the production of tissue engineering scaffolds, drug delivery systems, and medical models for educational purposes. The ability to create complex and customized structures with 3D printing technology is opening up new possibilities for medical research and treatment. As the Global 3D Printing Polymer Material for Medical Market continues to grow, the range of applications for these materials is expected to expand, offering new solutions for improving patient care and outcomes.

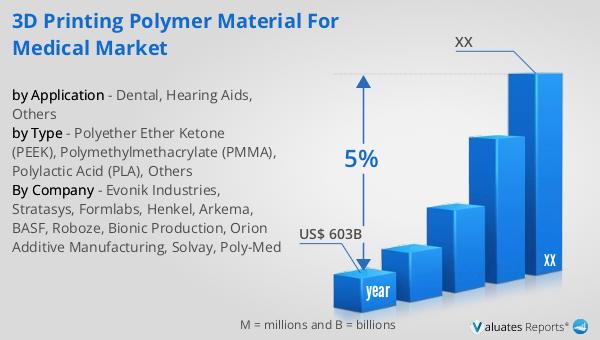

Global 3D Printing Polymer Material for Medical Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years.

| Report Metric | Details |

| Report Name | 3D Printing Polymer Material for Medical Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Evonik Industries, Stratasys, Formlabs, Henkel, Arkema, BASF, Roboze, Bionic Production, Orion Additive Manufacturing, Solvay, Poly-Med |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |