What is Global PET Packaging In the Pharmaceutical Market?

Global PET packaging in the pharmaceutical market refers to the use of polyethylene terephthalate (PET) materials for packaging pharmaceutical products. PET is a type of plastic that is lightweight, durable, and highly resistant to moisture and chemicals, making it an ideal choice for packaging medicines. In the pharmaceutical industry, packaging plays a crucial role in ensuring the safety, efficacy, and shelf life of medications. PET packaging is used for a wide range of pharmaceutical products, including liquid and solid medicines, due to its excellent barrier properties and ability to preserve the integrity of the contents. The global market for PET packaging in the pharmaceutical sector is driven by the increasing demand for safe and reliable packaging solutions, advancements in packaging technology, and the growing pharmaceutical industry worldwide. As healthcare needs continue to rise, the demand for PET packaging is expected to grow, providing a sustainable and efficient solution for pharmaceutical companies. The versatility and recyclability of PET also contribute to its popularity, as it aligns with the industry's focus on sustainability and environmental responsibility. Overall, PET packaging is a vital component in the pharmaceutical supply chain, ensuring that medicines reach consumers in optimal condition.

PET Bottles, PET Blister Packs, PET Infusion Bags, PET Films, Others in the Global PET Packaging In the Pharmaceutical Market:

PET bottles are one of the most common forms of PET packaging in the pharmaceutical market. They are used to store a variety of liquid medicines, such as syrups, suspensions, and solutions. The transparency of PET bottles allows for easy inspection of the contents, ensuring that the medicine is free from contamination or degradation. Additionally, PET bottles are lightweight and shatterproof, making them a safe option for transporting and storing medicines. PET blister packs are another popular form of packaging, particularly for solid medicines like tablets and capsules. These packs consist of a pre-formed plastic cavity sealed with a lidding material, usually aluminum foil. The use of PET in blister packs provides excellent protection against moisture, oxygen, and light, which can degrade the quality of the medicine. PET infusion bags are used for intravenous solutions and other liquid medications that require sterile packaging. These bags are designed to be flexible and durable, ensuring that the contents remain uncontaminated during storage and administration. PET films are used in various pharmaceutical packaging applications, including as a barrier layer in blister packs and as a protective coating for other packaging materials. The versatility of PET films allows for customization to meet specific packaging requirements, such as enhanced barrier properties or improved printability. Other forms of PET packaging in the pharmaceutical market include vials, ampoules, and jars, each designed to meet the unique needs of different types of medicines. The use of PET in these applications ensures that the packaging is not only functional but also aesthetically pleasing, with options for clear or colored finishes. Overall, PET packaging offers a range of benefits for the pharmaceutical industry, including improved safety, extended shelf life, and reduced environmental impact. As the demand for innovative and sustainable packaging solutions continues to grow, PET is likely to remain a key material in the pharmaceutical packaging market.

Liquid Medicine, Solid Medicine in the Global PET Packaging In the Pharmaceutical Market:

The usage of global PET packaging in the pharmaceutical market is particularly significant in the areas of liquid and solid medicines. For liquid medicines, PET packaging offers several advantages. The lightweight nature of PET bottles makes them easy to handle and transport, reducing the risk of breakage and contamination. The clarity of PET allows for visual inspection of the liquid, ensuring that it remains free from impurities. Additionally, PET's excellent barrier properties protect the liquid medicine from exposure to moisture, oxygen, and other environmental factors that could compromise its quality. This is particularly important for medicines that are sensitive to light or air, as PET packaging can help maintain their stability and efficacy over time. In the case of solid medicines, such as tablets and capsules, PET blister packs are widely used. These packs provide individual compartments for each dose, protecting the medicine from moisture and contamination. The use of PET in blister packs ensures that the medicine remains intact and effective until it is consumed. The transparency of PET also allows patients to easily identify the medicine and monitor their dosage. Furthermore, PET packaging is tamper-evident, providing an additional layer of security for both liquid and solid medicines. This is crucial in preventing unauthorized access and ensuring that the medicine reaches the patient in its intended form. The recyclability of PET also aligns with the pharmaceutical industry's focus on sustainability, as it allows for the packaging to be reused or repurposed, reducing waste and environmental impact. Overall, the use of PET packaging in the pharmaceutical market plays a vital role in ensuring the safety, efficacy, and sustainability of both liquid and solid medicines. As the demand for innovative and reliable packaging solutions continues to grow, PET is likely to remain a preferred choice for pharmaceutical companies worldwide.

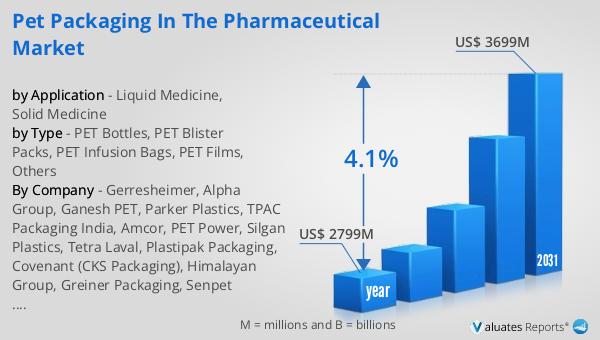

Global PET Packaging In the Pharmaceutical Market Outlook:

The global market for PET packaging in the pharmaceutical sector was valued at approximately $2,799 million in 2024. It is anticipated to expand to a revised size of about $3,699 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.1% over the forecast period. This growth is driven by the increasing demand for safe and reliable packaging solutions in the pharmaceutical industry, as well as advancements in packaging technology. The versatility and recyclability of PET make it an attractive option for pharmaceutical companies looking to enhance the safety and sustainability of their packaging. As healthcare needs continue to rise globally, the demand for PET packaging is expected to grow, providing a sustainable and efficient solution for pharmaceutical companies. The market outlook for PET packaging in the pharmaceutical sector is positive, with continued growth anticipated in the coming years. This growth is supported by the increasing focus on sustainability and environmental responsibility, as well as the need for innovative packaging solutions that meet the unique requirements of the pharmaceutical industry. Overall, the global market for PET packaging in the pharmaceutical sector is poised for continued expansion, driven by the growing demand for safe, reliable, and sustainable packaging solutions.

| Report Metric | Details |

| Report Name | PET Packaging In the Pharmaceutical Market |

| Accounted market size in year | US$ 2799 million |

| Forecasted market size in 2031 | US$ 3699 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gerresheimer, Alpha Group, Ganesh PET, Parker Plastics, TPAC Packaging India, Amcor, PET Power, Silgan Plastics, Tetra Laval, Plastipak Packaging, Covenant (CKS Packaging), Himalayan Group, Greiner Packaging, Senpet Polymers, AG Poly Packs Private, INOAC, Dongguan Fukang Plastic Products, Kang-Jia, Kaufman Container, Kian Joo Group, Sidel International, Plastek, Xin Fuda |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |