What is Global Silver Sintering Die Attach Paste Market?

The Global Silver Sintering Die Attach Paste Market is a niche but rapidly growing segment within the broader semiconductor materials industry. This market focuses on the production and sale of silver sintering die attach pastes, which are crucial components in the assembly of semiconductor devices. These pastes are used to create a strong mechanical bond between the semiconductor die and the substrate, ensuring efficient thermal and electrical conductivity. The unique property of silver sintering paste is its ability to provide a high thermal and electrical conductivity bond without the need for high-temperature reflow processes, making it ideal for sensitive electronic components. As the demand for more efficient and higher-performing electronic devices continues to rise, so does the need for advanced materials like silver sintering die attach pastes. These materials are essential in developing power semiconductor devices, RF power devices, high-performance LEDs, and other high-tech applications, driving the market's growth. The market's expansion is further fueled by the ongoing miniaturization of electronic devices and the increasing complexity of semiconductor designs, which require more reliable and efficient material solutions.

Pressure Sintering, Pressure-less Sintering in the Global Silver Sintering Die Attach Paste Market:

Diving into the Global Silver Sintering Die Attach Paste Market, we find two primary techniques at its core: Pressure Sintering and Pressure-less Sintering. These methods are pivotal in the manufacturing process of semiconductor devices, each with its unique advantages and applications. Pressure Sintering involves applying external pressure and heat to the silver sintering paste, facilitating the metal particles' fusion without melting them entirely. This method is known for producing highly reliable and thermally conductive bonds, making it suitable for high-power applications where device reliability is paramount. On the other hand, Pressure-less Sintering does not require external pressure, relying solely on heat to initiate the sintering process. This technique is advantageous for its lower processing costs and the ability to sinter large areas uniformly, making it ideal for applications where cost-effectiveness and scalability are critical. Both methods play a crucial role in the Global Silver Sintering Die Attach Paste Market, catering to a wide range of applications from power semiconductor devices to high-performance LEDs. The choice between pressure and pressure-less sintering depends on the specific requirements of the semiconductor device being manufactured, including thermal and electrical conductivity needs, mechanical strength, and processing cost considerations. As the market continues to evolve, the development of new sintering techniques and improvements in paste formulations are expected to further enhance the performance and reliability of semiconductor devices.

Power Semiconductor Device, RF Power Device, High Performance LED, Others in the Global Silver Sintering Die Attach Paste Market:

In the realm of the Global Silver Sintering Die Attach Paste Market, the usage of silver sintering die attach pastes spans across several critical areas, including Power Semiconductor Devices, RF Power Devices, High-Performance LEDs, among others. In Power Semiconductor Devices, these pastes are indispensable for ensuring efficient heat dissipation and reliable electrical connections, crucial for devices that manage high power levels. The superior thermal and electrical conductivity of silver sintering pastes significantly enhances device performance and longevity. RF Power Devices also benefit from the use of silver sintering pastes, where maintaining signal integrity is paramount. The pastes' excellent electrical conductivity ensures minimal signal loss, which is essential for devices operating at high frequencies. High-Performance LEDs are another area where these pastes find extensive application. The high thermal conductivity of silver sintering pastes helps manage the heat generated by LEDs, thereby improving light output and extending the lifespan of the devices. In other applications, such as in the assembly of complex semiconductor devices, silver sintering pastes provide a reliable solution for achieving strong mechanical bonds and efficient thermal management. The versatility and superior properties of these pastes make them a key material in the development and manufacturing of advanced electronic devices, driving innovation and performance improvements across the industry.

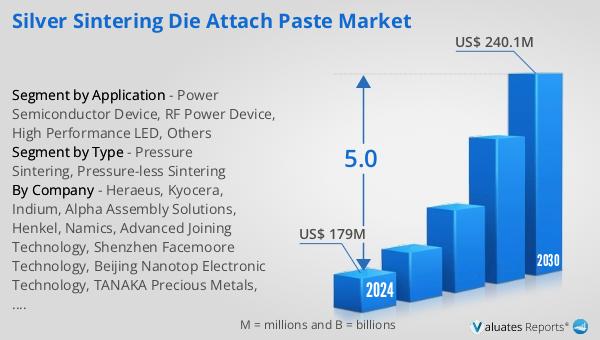

Global Silver Sintering Die Attach Paste Market Outlook:

The market outlook for the semiconductor industry presents a promising future, with the sector's value estimated at US$ 579 billion in 2022, and projections indicating a growth to US$ 790 billion by 2029. This growth trajectory, characterized by a Compound Annual Growth Rate (CAGR) of 6% during the forecast period, underscores the dynamic and expanding nature of the semiconductor market. Such growth is reflective of the increasing demand for semiconductor devices across various applications, driven by technological advancements and the proliferation of electronic devices in everyday life. The semiconductor industry's expansion is a testament to its critical role in powering the next generation of technology, from consumer electronics to industrial applications and beyond. As the industry continues to innovate and evolve, the market's upward trend is expected to persist, highlighting the sector's importance in the global technological landscape.

| Report Metric | Details |

| Report Name | Silver Sintering Die Attach Paste Market |

| Accounted market size in year | US$ 579 billion |

| Forecasted market size in 2029 | US$ 790 billion |

| CAGR | 6% |

| Base Year | year |

| Forecasted years | 2024 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Heraeus, Kyocera, Indium, Alpha Assembly Solutions, Henkel, Namics, Advanced Joining Technology, Shenzhen Facemoore Technology, TANAKA Precious Metals, Nihon Superior, Nihon Handa, NBE Tech, Solderwell Advanced Materials, Guangzhou Xianyi Electronic Technology, ShareX (Zhejiang) New Material Technology, Bando Chemical Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |