What is Global PCB Copper Foil Market?

The Global PCB Copper Foil Market is a specialized sector within the electronics industry, focusing on the production and distribution of copper foil used in the manufacturing of printed circuit boards (PCBs). This market plays a crucial role in the electronics manufacturing process, as copper foil is a key component in creating the conductive pathways necessary for the functioning of electronic devices. The demand for PCB copper foil is driven by the electronics industry's need for more efficient, smaller, and higher-performing devices. As technology advances, the requirements for finer lines and higher conductivity in PCBs increase, pushing the development of both the quality and the capabilities of copper foil. This market encompasses a range of copper foil types, including electrolytic copper foil and rolled copper foil, each suited to different applications within the PCB manufacturing process. The growth of this market is closely tied to the expansion of the electronics sector, including consumer electronics, automotive electronics, and communication devices, reflecting the integral role of PCBs in modern technology.

Electrolytic Copper Foil, Rolled Copper Foil in the Global PCB Copper Foil Market:

Electrolytic Copper Foil and Rolled Copper Foil are two pivotal materials in the Global PCB Copper Foil Market, each serving distinct purposes based on their unique properties. Electrolytic Copper Foil is manufactured through an electroplating process, resulting in a material that is highly ductile and can be made into very thin sheets, making it ideal for high-density PCBs used in sophisticated electronic devices. This type of copper foil features a grain structure that is beneficial for the adhesion of copper to the PCB substrate, a critical factor in the reliability of the final electronic component. On the other hand, Rolled Copper Foil is produced by mechanically pressing and rolling copper into thin sheets. This process yields a copper foil with a high degree of flexibility and a smooth surface, characteristics that are highly valued in the production of flexible printed circuit boards (FPCBs). Rolled Copper Foil is preferred for applications where bending and flexibility are necessary, such as in wearable electronics and foldable devices. Both types of copper foil are essential to the PCB manufacturing industry, with their selection depending on the specific requirements of the PCB design, including flexibility, conductivity, and the fineness of the circuit patterns. The Global PCB Copper Foil Market's dynamics are influenced by the evolving needs of the electronics industry, pushing for innovations in copper foil manufacturing to meet the demands for higher performance and more complex electronic devices.

Rigid Printed Circuit Board, Flexible Printed Circuit Board in the Global PCB Copper Foil Market:

In the realm of the Global PCB Copper Foil Market, the usage of copper foil spans across various applications, notably in the manufacturing of Rigid Printed Circuit Boards (PCBs) and Flexible Printed Circuit Boards (FPCBs). Rigid PCBs, which form the backbone of countless electronic devices, rely on copper foil for the creation of conductive pathways that facilitate the flow of electricity between different components. The copper foil used in these boards is prized for its conductivity, durability, and resistance to corrosion, making it an indispensable material in the production of reliable and efficient electronic devices. On the other hand, Flexible PCBs, which are increasingly popular in modern electronics for their ability to bend and flex, also depend on copper foil as a critical component. The flexibility of the copper foil used in FPCBs allows these boards to conform to various shapes and sizes, enabling innovative design possibilities in electronics, such as foldable smartphones and wearable technology. The use of copper foil in both rigid and flexible PCBs underscores its versatility and essential role in the electronics manufacturing process. As the electronics industry continues to evolve, with a growing emphasis on miniaturization, flexibility, and high performance, the demand for high-quality PCB copper foil is expected to rise, reflecting its pivotal position in the development of future electronic devices.

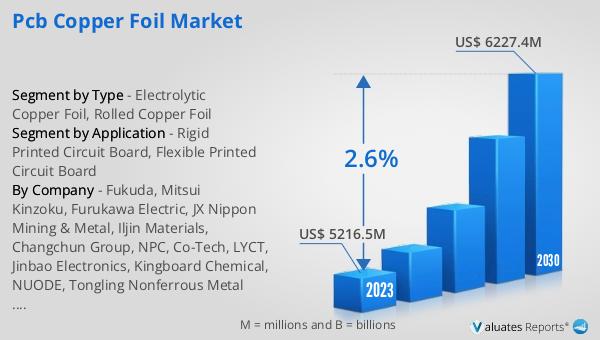

Global PCB Copper Foil Market Outlook:

The market outlook for the Global PCB Copper Foil sector presents a promising future, with its valuation at approximately $5216.5 million as of 2023. This figure is projected to ascend to around $6227.4 million by the year 2030, marking a steady Compound Annual Growth Rate (CAGR) of 2.6% throughout the period spanning from 2024 to 2030. This anticipated growth underscores the increasing reliance on PCB copper foil within the electronics industry, driven by the continuous demand for more sophisticated and high-performing electronic devices. The expansion of this market is indicative of the vital role that PCB copper foil plays in the manufacturing of printed circuit boards, which are fundamental components of virtually all electronic products. As technology progresses and the requirements for electronic devices become more complex, the need for high-quality copper foil, capable of supporting advanced PCB designs, is expected to surge. This outlook reflects the market's potential for growth and its importance in meeting the evolving needs of the electronics manufacturing sector.

| Report Metric | Details |

| Report Name | PCB Copper Foil Market |

| Accounted market size in 2023 | US$ 5216.5 million |

| Forecasted market size in 2030 | US$ 6227.4 million |

| CAGR | 2.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fukuda, Mitsui Kinzoku, Furukawa Electric, JX Nippon Mining & Metal, Iljin Materials, Changchun Group, NPC, Co-Tech, LYCT, Jinbao Electronics, Kingboard Chemical, NUODE, Tongling Nonferrous Metal Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |