What is Global Metal Powder Atomization Equipment Market?

The Global Metal Powder Atomization Equipment Market is a specialized sector within the broader materials engineering and manufacturing industry, focusing on the production of fine, powdered metals through various atomization techniques. This market caters to the growing demand for metal powders used in a variety of applications, from additive manufacturing (3D printing) to powder metallurgy and beyond. Atomization equipment is crucial in transforming bulk metals into fine particles by exposing them to a high-energy fluid or gas jet, which breaks the metal into small droplets that solidify into powder. This process is key to achieving the desired chemical composition, particle size, and shape required for specific applications, ensuring the performance and reliability of the end products. As industries continue to push the boundaries of technology and material science, the Global Metal Powder Atomization Equipment Market is poised for significant growth, driven by innovation and the expanding capabilities of metal powder applications across various sectors.

Gas Atomization Equipment, Water Atomization Equipment, Other in the Global Metal Powder Atomization Equipment Market:

Diving into the Global Metal Powder Atomization Equipment Market, we find it segmented into three main types of equipment: Gas Atomization Equipment, Water Atomization Equipment, and Other. Gas Atomization Equipment utilizes high-pressure gas to disperse molten metal into fine particles, favored for producing powders with low oxygen content and uniform particle sizes, ideal for high-performance applications in aerospace and automotive industries. Water Atomization Equipment, on the other hand, employs high-pressure water jets to achieve atomization, resulting in larger, more irregular particles. This method is cost-effective and widely used for mass production in sectors like construction and machinery manufacturing. The "Other" category encompasses various emerging and specialized atomization technologies, including plasma, ultrasonic, and centrifugal atomization, each offering unique advantages in terms of particle morphology and production efficiency. These technologies are being increasingly adopted for niche applications where specific material properties are critical. Together, these equipment types form the backbone of the Global Metal Powder Atomization Equipment Market, catering to a diverse range of industrial needs and driving innovation in material science and manufacturing processes.

3D Printing, Industrial Manufacturing, Other in the Global Metal Powder Atomization Equipment Market:

The usage of Global Metal Powder Atomization Equipment Market spans across several key areas, notably 3D Printing, Industrial Manufacturing, and Other applications. In 3D Printing, metal powders produced by atomization equipment are essential for creating complex, high-strength, and lightweight components used in aerospace, automotive, and medical devices. The precision and quality of the powder directly influence the printing process's efficiency and the final product's properties. Industrial Manufacturing benefits from metal powders in producing parts through powder metallurgy, offering advantages in material utilization, waste reduction, and the ability to create components with complex geometries that would be challenging to achieve through traditional manufacturing methods. Other applications include research and development in material science, where atomized powders are used to explore new materials and composites, potentially leading to breakthroughs in various industries. The versatility and efficiency of metal powder atomization equipment in producing high-quality powders tailored to specific applications underscore its critical role in advancing manufacturing and material innovation.

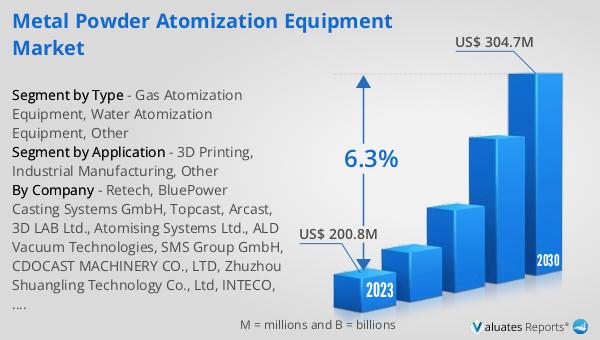

Global Metal Powder Atomization Equipment Market Outlook:

Regarding the market outlook for the Global Metal Powder Atomization Equipment Market, it's observed that the market, which was valued at approximately $200.8 million in 2023, is on a trajectory to expand to around $304.7 million by the year 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.3% throughout the forecast period spanning from 2024 to 2030. This projection underscores the increasing reliance on metal powder atomization equipment across various industries, driven by the growing demand for high-quality metal powders used in advanced manufacturing processes, including 3D printing and powder metallurgy. The anticipated growth reflects the market's response to the evolving needs of the manufacturing sector, highlighting the importance of atomization technology in enabling innovations and improving efficiencies in material production. As industries continue to seek out more sustainable and cost-effective manufacturing solutions, the Global Metal Powder Atomization Equipment Market is set to play a pivotal role in meeting these demands, marking a significant period of expansion and technological advancement in the coming years.

| Report Metric | Details |

| Report Name | Metal Powder Atomization Equipment Market |

| Accounted market size in 2023 | US$ 200.8 million |

| Forecasted market size in 2030 | US$ 304.7 million |

| CAGR | 6.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Retech, BluePower Casting Systems GmbH, Topcast, Arcast, 3D LAB Ltd., Atomising Systems Ltd., ALD Vacuum Technologies, SMS Group GmbH, CDOCAST MACHINERY CO., LTD, Zhuzhou Shuangling Technology Co., Ltd, INTECO, Sandvik, 3D ENERGY, Phoenix Scientific Industries Ltd (PSI), ECPlaza |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |