What is Global Medical Grade Pad Printing Ink Market?

The Global Medical Grade Pad Printing Ink Market is a specialized segment within the printing ink industry, focusing on inks used for printing on medical devices and equipment. These inks are designed to meet stringent health and safety standards, ensuring that they are safe for use in medical environments. Medical grade pad printing inks are used to print on various surfaces, including plastics, metals, and silicones, which are commonly found in medical devices. The inks are formulated to provide durable, long-lasting prints that can withstand sterilization processes and resist chemicals, ensuring that markings remain legible over the life of the medical device. This market caters to a wide range of applications, from printing on surgical instruments and medical packaging to labeling disposable syringes and catheters. As the medical industry continues to grow and evolve, the demand for high-quality, compliant printing inks rises, driving the development of advanced ink formulations to meet the specific needs of medical device manufacturers.

Solvent-based, UV Curing in the Global Medical Grade Pad Printing Ink Market:

The Global Medical Grade Pad Printing Ink Market is segmented into solvent-based and UV curing inks, each with its unique properties and applications. Solvent-based inks are traditional inks that dry through the evaporation of solvents, leaving the pigment behind on the substrate. These inks are known for their versatility and can adhere to a variety of materials, making them suitable for many medical devices. However, they require proper ventilation during the printing process to manage solvent emissions, posing environmental and health concerns. On the other hand, UV curing inks dry instantly when exposed to ultraviolet light, offering a faster printing process and reduced drying time. This feature makes UV curing inks highly efficient for high-volume production environments. They also have the advantage of being more environmentally friendly, as they do not emit volatile organic compounds (VOCs). UV curing inks provide excellent adhesion and durability, which are critical for medical devices that undergo frequent handling and sterilization. The choice between solvent-based and UV curing inks depends on various factors, including the substrate material, desired durability, and environmental considerations. As the medical industry increasingly focuses on sustainability and safety, UV curing inks are gaining popularity, driving innovations in ink formulations to enhance performance and meet stringent medical standards.

PPE, Medical Device in the Global Medical Grade Pad Printing Ink Market:

In the Global Medical Grade Pad Printing Ink Market, these inks find extensive usage in two critical areas: Personal Protective Equipment (PPE) and Medical Devices. For PPE, the inks are used to print instructions, sizes, and branding on items such as surgical masks, gloves, and gowns. The durability of the ink is paramount, as these items often undergo rigorous sterilization processes. The ink must adhere well to various materials, including non-woven fabrics and plastics, ensuring that the print remains legible and intact throughout the product's lifecycle. In the realm of medical devices, pad printing inks are utilized to mark instruments and equipment with vital information such as measurement indicators, operating instructions, and brand logos. These markings are crucial for the safe and effective use of medical devices, requiring the ink to be resistant to chemicals, abrasions, and sterilization methods. The inks used in both PPE and medical devices must comply with strict regulatory standards to ensure they are safe for direct or indirect contact with patients. As the demand for medical supplies and devices grows, the need for high-quality, compliant medical grade pad printing inks continues to rise, highlighting the importance of these inks in ensuring the safety and functionality of medical products.

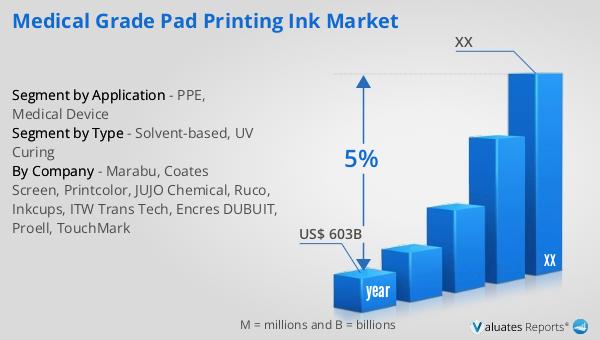

Global Medical Grade Pad Printing Ink Market Outlook:

Our research indicates that the global market for medical devices is currently valued at approximately US$ 603 billion as of the year 2023. This market is on a growth trajectory, with expectations to expand at a Compound Annual Growth Rate (CAGR) of 5% over the next six years. This growth is reflective of the increasing demand for medical devices across various healthcare sectors, driven by technological advancements, an aging population, and a growing focus on healthcare and wellness worldwide. The expansion of the medical device market underscores the importance of innovation and development in the healthcare industry, as manufacturers strive to meet the evolving needs of patients and healthcare providers. This growth trend also highlights the potential for businesses within the medical device supply chain, including those involved in the production of medical grade pad printing inks, to capitalize on the expanding market opportunities. As the market continues to grow, the demand for high-quality, compliant medical devices will further drive the need for specialized materials and components, including medical grade inks used in the labeling and branding of these devices.

| Report Metric | Details |

| Report Name | Medical Grade Pad Printing Ink Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Marabu, Coates Screen, Printcolor, JUJO Chemical, Ruco, Inkcups, ITW Trans Tech, Encres DUBUIT, Proell, TouchMark |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |