What is Global Conformal Coating in Electronics Market?

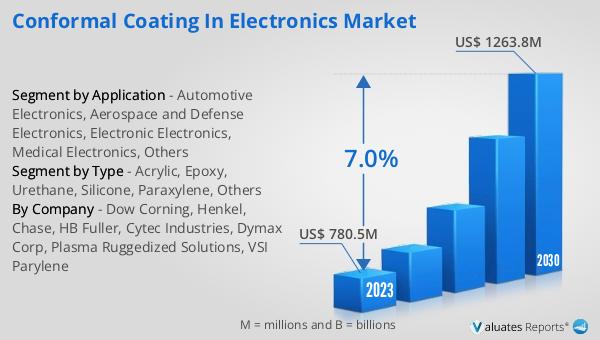

The Global Conformal Coating in Electronics Market refers to a specialized sector focused on the application of protective chemical coatings to electronic circuit boards and components. These coatings are designed to shield electronics from environmental hazards such as moisture, dust, chemicals, and temperature variations, thereby enhancing their durability and performance. Conformal coatings are essential in extending the life of electronic devices by preventing corrosion and electrical failures. The market encompasses a variety of coating types, each tailored to meet specific protective requirements and application processes in the electronics industry. As electronics become increasingly integral to various aspects of modern life, the demand for reliable and durable electronic devices drives the growth of the conformal coating market. With advancements in technology and materials science, the market is continuously evolving, offering innovative solutions to protect complex and miniaturized electronic components. As of 2023, the market's significance is underscored by its valuation at US$ 780.5 million, with projections indicating a growth trajectory that could reach US$ 1263.8 million by 2030, reflecting the critical role of conformal coatings in the electronics sector's future.

Acrylic, Epoxy, Urethane, Silicone, Paraxylene, Others in the Global Conformal Coating in Electronics Market:

In the realm of the Global Conformal Coating in Electronics Market, various materials such as Acrylic, Epoxy, Urethane, Silicone, and Paraxylene, among others, play pivotal roles. Acrylic coatings are prized for their ease of application and removal, making them ideal for general protection where frequent rework is anticipated. They offer good resistance to moisture and mild abrasions, serving as a versatile choice for many electronic applications. Epoxy coatings, on the other hand, are known for their exceptional hardness and resistance to chemicals and humidity, providing robust protection for electronic components in harsh environments. Urethane coatings stand out for their excellent resistance to chemicals, abrasions, and solvents, making them suitable for high-reliability applications where durability is paramount. Silicone coatings are distinguished by their superior flexibility and high-temperature resistance, which are crucial in applications subject to extreme temperature variations. Paraxylene, though less common, offers unique properties such as very thin coating capabilities and excellent barrier properties, catering to specialized electronic applications. Each of these materials brings specific advantages to the table, allowing for tailored protective solutions across a wide range of electronic devices and environments. As the electronics industry continues to evolve, the demand for these conformal coatings is expected to rise, driven by the need for more durable, reliable, and high-performing electronic components.

Automotive Electronics, Aerospace and Defense Electronics, Electronic Electronics, Medical Electronics, Others in the Global Conformal Coating in Electronics Market:

The usage of the Global Conformal Coating in Electronics Market spans several critical sectors, including Automotive Electronics, Aerospace and Defense Electronics, Consumer Electronics, Medical Electronics, among others. In the automotive sector, conformal coatings are essential for ensuring the reliability and longevity of electronic components exposed to harsh conditions such as moisture, salt, and temperature fluctuations. These coatings protect sensors, control units, and other vital electronics that are integral to the safety and functionality of modern vehicles. In aerospace and defense, the demand for conformal coatings is driven by the need for electronics that can withstand extreme environmental conditions and mechanical stresses. These coatings safeguard avionics and military hardware, ensuring performance and reliability in critical missions. Consumer electronics benefit from conformal coatings by enhancing the durability of devices such as smartphones, tablets, and wearables, protecting them from spills, humidity, and everyday wear and tear. In the medical electronics field, conformal coatings play a crucial role in ensuring the reliability of devices that are exposed to sterilization processes and bodily fluids, contributing to patient safety and device longevity. The diverse applications of conformal coatings across these sectors underscore their importance in the electronics market, highlighting the need for continuous innovation and quality improvement to meet the evolving demands of these industries.

Global Conformal Coating in Electronics Market Outlook:

The market outlook for the Global Conformal Coating in Electronics sector presents a promising future, with the market's value standing at US$ 780.5 million as of 2023. This figure is expected to surge to US$ 1263.8 million by the year 2030, marking a Compound Annual Growth Rate (CAGR) of 7.0% throughout the forecast period spanning from 2024 to 2030. This growth trajectory underscores the increasing reliance on electronic devices across various industries and the critical need to protect these devices from environmental challenges. As electronics continue to permeate every aspect of daily life and industrial operations, the demand for effective conformal coatings is set to rise, driven by the need for enhanced durability and reliability of electronic components. This market expansion reflects the growing awareness of the benefits of conformal coatings in safeguarding electronics against moisture, dust, chemical exposure, and temperature extremes, thereby ensuring their optimal performance and extended lifespan. The projected growth in the conformal coating market highlights its pivotal role in the electronics industry, emphasizing the importance of continued innovation and development in coating technologies to meet the evolving needs of electronic device manufacturers and consumers alike.

| Report Metric | Details |

| Report Name | Conformal Coating in Electronics Market |

| Accounted market size in 2023 | US$ 780.5 million |

| Forecasted market size in 2030 | US$ 1263.8 million |

| CAGR | 7.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dow Corning, Henkel, Chase, HB Fuller, Cytec Industries, Dymax Corp, Plasma Ruggedized Solutions, VSI Parylene |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |