What is Global Closed Die Forging Market?

The Global Closed Die Forging Market is a specialized sector within the manufacturing industry, focusing on the process of shaping metal through compressive forces. This market involves the use of dies that enclose the workpiece, allowing for complex shapes to be produced with high precision and excellent surface finish. Closed die forging, also known as impression die forging, is crucial in producing parts that demand strength, reliability, and durability. The technique is widely applied across various industries, including automotive, aerospace, and industrial machinery, due to its ability to create parts that can withstand extreme conditions and stress. The process involves the metal being placed in a die resembling a mold, after which it is hammered or pressed until it fills the die cavity, taking its shape. This method not only ensures superior mechanical properties but also allows for mass production of components with minimal waste, making it a cost-effective option for high-volume manufacturing. The global market for closed die forging is driven by the increasing demand for high-quality forged parts in industrial applications, coupled with advancements in forging technology that enhance efficiency and productivity.

Steel, Aluminum, Alloy in the Global Closed Die Forging Market:

Diving into the materials used in the Global Closed Die Forging Market, we find steel, aluminum, and alloys at the forefront of preferred materials due to their distinct properties and benefits in various applications. Steel, known for its exceptional strength and durability, is a primary choice for components that require high resistance to wear and tear, making it ideal for the automotive and aerospace sectors. The versatility of steel allows for a wide range of properties to be achieved through different alloys and heat treatment processes, catering to specific needs within industrial applications. Aluminum, on the other hand, is favored for its lightweight characteristics combined with good strength, making it suitable for applications where reducing weight is crucial, such as in aerospace and transportation. Its ability to resist corrosion and conduct heat efficiently also makes aluminum a popular choice in electrical and thermal applications. Alloys, including those of titanium, nickel, and copper, are selected for their unique properties, such as high-temperature resistance in aerospace engines or superior conductivity in electrical components. These materials are meticulously chosen based on the requirements of the end product, including strength, weight, conductivity, and resistance to environmental factors, making them integral to the success and innovation within the Global Closed Die Forging Market. The selection and use of these materials are guided by the end-use application's specific demands, driving the market's growth by catering to the evolving needs of industries reliant on forged components.

Automotive, Aerospace, Agricultural, General Industrial, Others in the Global Closed Die Forging Market:

The Global Closed Die Forging Market plays a pivotal role in various sectors, notably in automotive, aerospace, agricultural, general industrial, and other areas, by providing essential components that contribute to the functionality and reliability of end products. In the automotive industry, closed die forging is utilized to produce parts such as crankshafts, connecting rods, and transmission gears, which are critical for vehicle performance and safety. The aerospace sector relies on this process for manufacturing structural components, engine parts, and landing gear assemblies, where strength-to-weight ratio and resistance to extreme conditions are paramount. Agricultural machinery benefits from forged parts in terms of durability and wear resistance, enhancing the efficiency and lifespan of equipment used in farming activities. General industrial applications encompass a broad range of products, including tools, hardware, and machinery components, where the superior mechanical properties of forged items are essential for operational reliability and safety. Other areas, such as energy, mining, and construction, also depend on the high-quality parts produced through closed die forging, demonstrating the market's versatility and critical role in supporting the infrastructure and technological advancement of various sectors. The widespread usage of closed die forging across these industries underscores its importance in modern manufacturing and engineering, driving continuous innovation and development within the market.

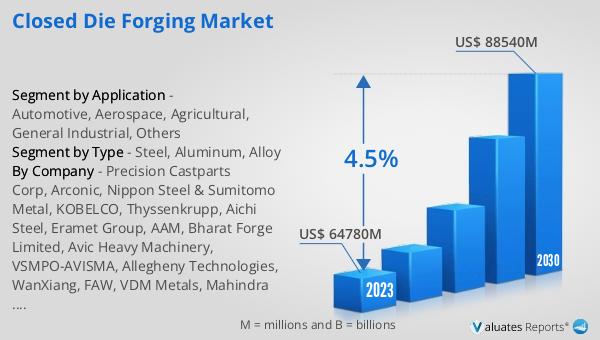

Global Closed Die Forging Market Outlook:

Regarding the market outlook for the Global Closed Die Forging Market, it's observed that the sector was valued at approximately 64,780 million US dollars in the year 2023. Looking ahead, projections suggest a growth trajectory that could see the market's value ascend to around 88,540 million US dollars by the year 2030. This anticipated growth, marked by a compound annual growth rate (CAGR) of 4.5% during the forecast period spanning from 2024 to 2030, underscores the dynamic nature of the market and its potential for expansion in the coming years. Such growth is indicative of the increasing demand for forged components across various industries, driven by the need for parts that offer superior strength, precision, and durability. The closed die forging process, with its ability to produce complex shapes and high-quality finishes, remains a critical manufacturing method for meeting the stringent requirements of sectors such as automotive, aerospace, and industrial machinery. This positive outlook reflects the market's resilience and adaptability in the face of evolving technological and material advancements, positioning it for continued success and innovation in the global manufacturing landscape.

| Report Metric | Details |

| Report Name | Closed Die Forging Market |

| Accounted market size in 2023 | US$ 64780 million |

| Forecasted market size in 2030 | US$ 88540 million |

| CAGR | 4.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Precision Castparts Corp, Arconic, Nippon Steel & Sumitomo Metal, KOBELCO, Thyssenkrupp, Aichi Steel, Eramet Group, AAM, Bharat Forge Limited, Avic Heavy Machinery, VSMPO-AVISMA, Allegheny Technologies, WanXiang, FAW, VDM Metals, Mahindra Forgings Europe, JSW, CITIC Heavy Industries, Scot Forge, Farinia Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |