What is Global Plastic Injection Molder Market?

The Global Plastic Injection Molder Market is a vast and dynamic sector that plays a crucial role in various industries worldwide. Plastic injection molding is a manufacturing process for producing parts by injecting molten material into a mold. The material is fed into a heated barrel, mixed, and forced into a mold cavity, where it cools and hardens to the configuration of the cavity. The global market for this process is vast, encompassing a wide range of industries and applications. The market's value is determined by the demand for plastic injection molded parts in various sectors, including automotive, consumer goods, packaging, healthcare, and others. The market's growth is driven by factors such as the increasing demand for plastic components in various industries, advancements in molding technologies, and the growing focus on reducing production costs and improving product quality. However, the market also faces challenges such as the high initial investment required for setting up molding facilities and the environmental concerns associated with plastic waste. Despite these challenges, the Global Plastic Injection Molder Market continues to grow, offering numerous opportunities for manufacturers, suppliers, and end-users.

Clamping Force (<250T), Clamping Force (250-650T), Clamping Force (>650T) in the Global Plastic Injection Molder Market:

The Global Plastic Injection Molder Market is segmented based on clamping force into three categories: Clamping Force (<250T), Clamping Force (250-650T), and Clamping Force (>650T). The clamping force of a plastic injection molder is the force applied to the mold to keep it closed during the injection process. The clamping force required depends on the size and complexity of the part being produced, as well as the type of material being used. Clamping Force (<250T) molders are typically used for producing small and medium-sized parts, while Clamping Force (250-650T) and Clamping Force (>650T) molders are used for larger and more complex parts. Each category has its own set of advantages and disadvantages, and the choice of molder depends on the specific requirements of the production process. The demand for each category varies across different industries and regions, depending on factors such as the type of products being manufactured, the production volume, and the available resources.

General Plastic, Automotive, Home Appliance, 3C Electronic, Medical, Others in the Global Plastic Injection Molder Market:

The Global Plastic Injection Molder Market finds usage in various areas including General Plastic, Automotive, Home Appliance, 3C Electronic, Medical, Others. In the General Plastic sector, it is used for producing a wide range of products such as containers, packaging materials, toys, and others. In the Automotive sector, it is used for manufacturing various components such as bumpers, interior parts, and others. In the Home Appliance sector, it is used for producing parts for appliances such as refrigerators, washing machines, and others. In the 3C Electronic sector, it is used for manufacturing components for electronic devices such as smartphones, laptops, and others. In the Medical sector, it is used for producing medical devices and equipment. In the Others sector, it is used for various other applications. The demand for plastic injection molded parts in these sectors is driven by factors such as the increasing production of consumer goods, the growing automotive industry, the rising demand for electronic devices, and the expanding healthcare sector.

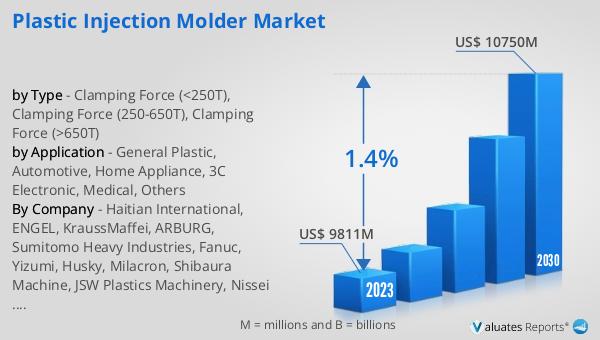

Global Plastic Injection Molder Market Outlook:

The future outlook for the Global Plastic Injection Molder Market is promising. In 2022, the market was valued at US$ 11800 million. It is projected to grow at a steady pace, reaching a value of US$ 13010 million by 2029. This represents a compound annual growth rate (CAGR) of 1.1% during the forecast period from 2023 to 2029. This growth is expected to be driven by factors such as the increasing demand for plastic components in various industries, advancements in molding technologies, and the growing focus on reducing production costs and improving product quality. However, the market also faces challenges such as the high initial investment required for setting up molding facilities and the environmental concerns associated with plastic waste. Despite these challenges, the market is expected to continue its upward trajectory, offering numerous opportunities for manufacturers, suppliers, and end-users.

| Report Metric | Details |

| Report Name | Plastic Injection Molder Market |

| Accounted market size in 2022 | US$ 11800 million |

| Forecasted market size in 2029 | US$ 13010 million |

| CAGR | 1.1% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Haitian International, ENGEL Holding GmbH, ARBURG GmbH, KraussMaffei, Sumitomo Heavy Industries, Fanuc, Yizumi, Husky, Chenhsong, Milacron, Nissei Plastic, Shibaura Machine, JSW Plastics Machinery, Toyo, LK Technology, Wittmann Battenfeld, UBE Machinery, Tederic, Cosmos Machinery, Windsor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |