What is Global Anti-Corrosion Coatings for Petrifaction Market?

The Global Anti-Corrosion Coatings for Petrifaction Market is a specialized sector that focuses on the production and distribution of anti-corrosion coatings specifically designed for petrifaction, or the process of turning substances into stone or a stony substance. These coatings are crucial in industries where materials are exposed to harsh environments and corrosive substances, such as the petrochemical industry. The market is driven by the need to protect infrastructure and equipment from damage, prolong their lifespan, and reduce maintenance and replacement costs. The coatings work by providing a barrier between the material and the corrosive substance, preventing or slowing down the corrosion process. The market includes various types of coatings, each with its unique properties and applications. The global market is continuously growing, driven by the increasing demand from various end-use industries, technological advancements, and the development of more efficient and environmentally friendly products.

Solvent Based Coatings, Water-Based Paint, Powder Coating in the Global Anti-Corrosion Coatings for Petrifaction Market:

The Global Anti-Corrosion Coatings for Petrifaction Market includes several types of coatings, namely Solvent Based Coatings, Water-Based Paint, and Powder Coating. Solvent Based Coatings are made up of liquefying agents that evaporate via a chemical reaction with oxygen. These coatings are known for their durability, excellent adhesion, and resistance to harsh conditions, making them suitable for heavy-duty applications. Water-Based Paint, on the other hand, is a type of coating where water is used as a dispersal agent for the resin. These paints are environmentally friendly, easy to apply, and have low toxicity and flammability levels. Lastly, Powder Coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, it requires no solvent to keep the binder and filler parts in a liquid suspension form. It's used for creating a hard finish that is tougher than conventional paint. Each of these coatings has its advantages and is used based on the requirements of the application.

Storage Tank, Petrochemical Pipeline, The Reaction, Other in the Global Anti-Corrosion Coatings for Petrifaction Market:

The Global Anti-Corrosion Coatings for Petrifaction Market finds its application in several areas such as Storage Tanks, Petrochemical Pipelines, The Reaction, and Others. Storage Tanks in the petrochemical industry often store corrosive substances and are thus susceptible to corrosion. Anti-corrosion coatings help in prolonging the life of these tanks and reducing maintenance costs. Similarly, Petrochemical Pipelines are used for transporting petrochemicals and are exposed to the harsh external environment and corrosive substances. The coatings protect these pipelines from corrosion, reducing the risk of leaks and accidents. In the Reaction process, various substances are mixed, often leading to corrosive by-products. The coatings protect the reaction vessels and other equipment from these corrosive substances. Other applications include protecting equipment and infrastructure in various industries from corrosion.

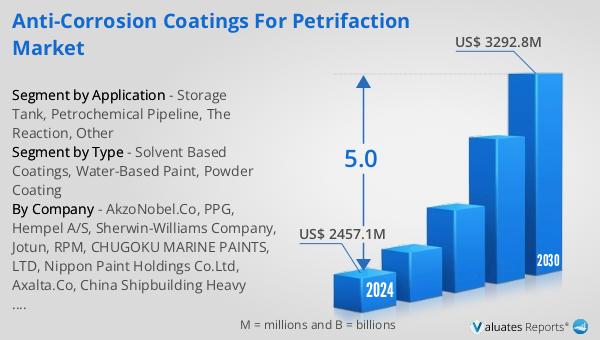

Global Anti-Corrosion Coatings for Petrifaction Market Outlook:

The Global Anti-Corrosion Coatings for Petrifaction Market is a dynamic and growing market. As of 2023, the market was valued at US$ 2330.7 million and is projected to reach US$ 3292.8 million by 2030, growing at a CAGR of 5.0% during the forecast period 2024-2030. North America is the second-largest producer of coatings for the petrochemical industry, contributing 21.39% to the global production in 2019. The market is dominated by major foreign manufacturers such as Akzo Nobel, PPG, Shanghai Old Man, Sherwin-Williams, Jotun, RPM, Tu, Nippon Paint, and YiShi. Among these, Akzo Nobel, PPG, Shanghai Old Man, Jotun, and Sherwin-Williams are the top five manufacturers, accounting for about 51.37% of the market output value in 2019. These companies have a significant influence on the global market, shaping its trends and developments.

| Report Metric | Details |

| Report Name | Anti-Corrosion Coatings for Petrifaction Market |

| Accounted market size in 2023 | US$ 2330.7 million |

| Forecasted market size in 2030 | US$ 3292.8 million |

| CAGR | 5.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AkzoNobel.Co, PPG, Hempel A/S, Sherwin-Williams Company, Jotun, RPM, CHUGOKU MARINE PAINTS, LTD, Nippon Paint Holdings Co.Ltd, Axalta.Co, China Shipbuilding Heavy Industry Shuangrui Technology Holding Co., Ltd., Kansai Paint Co.,Ltd., Xiangjiang Paint Group, Zhejiang Yutong New Materials Co., Ltd., Zhejiang Bridge Painting Co. LTD, YUNG CHI PAINT & VARNISH MFG. CO.,LTD, Jiangsu Changjiang Paint Company Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |