What is Global Surface Protection Tape Market?

The Global Surface Protection Tape Market is a specialized segment within the broader adhesive tape industry, focusing on tapes designed to protect surfaces from damage during manufacturing, transportation, and installation processes. These tapes are crucial in various industries, including automotive, electronics, construction, and appliances, where they safeguard surfaces from scratches, dust, and other potential damages. Surface protection tapes are typically made from materials like polyethylene, polypropylene, and polyvinyl chloride, each offering unique properties that cater to different protection needs. The market is driven by the increasing demand for consumer electronics, the growth of the automotive industry, and the rising construction activities worldwide. As industries continue to innovate and develop new products, the need for reliable surface protection solutions becomes more pronounced, making this market an essential component of modern manufacturing and logistics. The market's growth is also supported by advancements in adhesive technologies, which enhance the performance and versatility of these tapes, allowing them to adhere to various surfaces without leaving residues or causing damage upon removal. Overall, the Global Surface Protection Tape Market plays a vital role in ensuring the quality and integrity of products across multiple sectors.

LDPE, PP, PVC in the Global Surface Protection Tape Market:

LDPE (Low-Density Polyethylene), PP (Polypropylene), and PVC (Polyvinyl Chloride) are three primary materials used in the production of surface protection tapes, each offering distinct characteristics that make them suitable for different applications within the Global Surface Protection Tape Market. LDPE is known for its flexibility, transparency, and resistance to moisture, making it an ideal choice for protecting surfaces that require a clear view or need to withstand humid conditions. Its low-density nature allows it to conform easily to various shapes and surfaces, providing a snug fit that ensures comprehensive protection. LDPE tapes are commonly used in the automotive and electronics industries, where they protect delicate surfaces from scratches and dust during assembly and transportation. PP, on the other hand, is valued for its strength, chemical resistance, and durability. It is often used in applications where the tape needs to withstand harsh environmental conditions or exposure to chemicals. PP tapes are frequently employed in the construction and industrial sectors, where they protect surfaces from damage during heavy-duty operations. Their robust nature ensures that they can endure the rigors of construction sites and industrial environments without compromising the integrity of the surfaces they protect. PVC, known for its versatility and excellent adhesive properties, is widely used in applications that require a strong bond and resistance to wear and tear. PVC tapes are often used in the appliance and furniture industries, where they protect surfaces from scratches and abrasions during manufacturing and transportation. The material's ability to adhere securely to various surfaces makes it a popular choice for protecting high-value items that require reliable surface protection. Additionally, PVC tapes are available in a range of colors and thicknesses, allowing manufacturers to choose the best option for their specific needs. Each of these materials contributes to the overall effectiveness and versatility of surface protection tapes, enabling them to meet the diverse requirements of different industries. As the demand for surface protection solutions continues to grow, manufacturers are constantly exploring new formulations and technologies to enhance the performance of LDPE, PP, and PVC tapes, ensuring they remain at the forefront of the Global Surface Protection Tape Market.

Polished Metals, Plastic, Glass Materials, Others in the Global Surface Protection Tape Market:

The usage of Global Surface Protection Tape Market extends across various materials, including polished metals, plastic, glass materials, and others, each requiring specific protection solutions to maintain their integrity and appearance. In the case of polished metals, surface protection tapes are essential in preventing scratches, abrasions, and other forms of damage that can occur during manufacturing, transportation, and installation. These tapes provide a protective barrier that preserves the metal's finish, ensuring it remains pristine and free from blemishes. This is particularly important in industries such as automotive and aerospace, where the aesthetic and functional quality of metal components is crucial. For plastic materials, surface protection tapes offer a safeguard against scratches, dust, and chemical exposure, which can compromise the material's appearance and performance. Plastics are widely used in various industries, including electronics, packaging, and consumer goods, where maintaining their visual appeal and structural integrity is vital. Surface protection tapes help manufacturers deliver high-quality plastic products that meet consumer expectations. Glass materials, often used in construction, automotive, and electronics, also benefit from surface protection tapes. These tapes prevent scratches and chips that can occur during handling and installation, ensuring the glass remains clear and free from defects. This is particularly important for products like smartphones, tablets, and architectural glass, where clarity and precision are paramount. Additionally, surface protection tapes are used in other areas, such as wood, laminates, and painted surfaces, where they provide a protective layer that prevents damage during various stages of production and transportation. The versatility of surface protection tapes makes them an indispensable tool in ensuring the quality and longevity of a wide range of materials across different industries. As manufacturers continue to innovate and develop new products, the demand for effective surface protection solutions will continue to grow, driving the expansion of the Global Surface Protection Tape Market.

Global Surface Protection Tape Market Outlook:

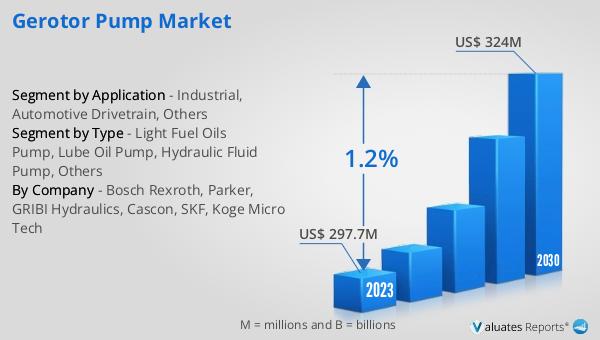

In 2024, the global market size for Surface Protection Tape was valued at approximately US$ 1,185 million, with projections indicating it could reach around US$ 1,502 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.5% during the forecast period from 2025 to 2031. China stands out as the leading producer of Surface Protection Tape, commanding a market share exceeding 40%, followed by regions such as North America and Europe. Key players in this industry include 3M, Tesa Tape, Surface Armor, NITTO DENKO, TUFTAPE FZCO, Surface Guard, MAIN TAPE, Brite Coatings, Ecoplast, and MBK Tape Solutions. Despite the presence of these major manufacturers, the top 10 companies collectively hold less than 15% of the market share, indicating a highly fragmented market landscape. This fragmentation suggests a competitive environment where numerous players contribute to the market dynamics, offering a wide range of products to meet diverse consumer needs. The market's growth is driven by increasing demand across various industries, including automotive, electronics, and construction, where surface protection tapes play a crucial role in safeguarding products during manufacturing and transportation. As the market continues to evolve, manufacturers are likely to focus on innovation and product development to maintain their competitive edge and capture a larger share of this expanding market.

| Report Metric | Details |

| Report Name | Surface Protection Tape Market |

| CAGR | 3.5% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | 3M, Tesa Tape, Surface Armor, NITTO DENKO, TUFTAPE FZCO, Surface Guard, MAIN TAPE, Brite Coatings, Ecoplast, MBK Tape Solutions |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |