What is Global High Purity Medical Helium Market?

The Global High Purity Medical Helium Market refers to the specialized segment of the helium market that focuses on providing helium of extremely high purity for medical applications. Helium, a noble gas, is known for its unique properties such as low boiling point, non-reactivity, and high thermal conductivity, making it indispensable in various medical technologies. High purity medical helium is essential for applications that require stringent quality and safety standards, such as Magnetic Resonance Imaging (MRI) systems and other advanced medical equipment. The demand for high purity medical helium is driven by the increasing prevalence of chronic diseases, advancements in medical technology, and the growing need for precise diagnostic tools. This market is characterized by rigorous quality control measures, specialized production processes, and a focus on ensuring the highest levels of purity to meet the specific needs of the healthcare industry. The global high purity medical helium market is a critical component of the broader medical gases market, playing a vital role in enhancing the capabilities of modern medical diagnostics and treatments.

Liquid Helium, Helium Gas in the Global High Purity Medical Helium Market:

Liquid helium and helium gas are two forms of helium that are extensively used in the Global High Purity Medical Helium Market. Liquid helium is primarily utilized in applications that require extremely low temperatures, such as cooling the superconducting magnets in MRI systems. The unique property of liquid helium to reach temperatures close to absolute zero makes it an ideal coolant for these high-tech medical devices. The process of liquefying helium involves cooling it to below its boiling point of -268.9 degrees Celsius, which requires sophisticated equipment and technology. On the other hand, helium gas is used in various medical applications, including as a carrier gas in respiratory treatments and in gas mixtures for specific medical procedures. Helium gas is preferred in these applications due to its inert nature, which ensures that it does not react with other substances and maintains the integrity of the medical treatments. The production of high purity helium gas involves several stages of purification to remove impurities and achieve the desired level of purity. Both liquid helium and helium gas play crucial roles in the medical field, with their applications extending beyond MRI systems to include other advanced diagnostic and therapeutic technologies. The demand for high purity medical helium is expected to grow as the healthcare industry continues to advance and the need for precise and reliable medical equipment increases. The production and supply of high purity medical helium require stringent quality control measures and adherence to international standards to ensure the safety and efficacy of medical applications. The global high purity medical helium market is supported by a network of specialized suppliers and manufacturers who are dedicated to meeting the specific needs of the healthcare industry. These suppliers invest in advanced technologies and processes to produce helium of the highest purity, ensuring that it meets the stringent requirements of medical applications. The market is also influenced by factors such as the availability of helium resources, technological advancements in helium production, and regulatory frameworks governing the use of medical gases. As the demand for high purity medical helium continues to rise, the market is expected to witness significant growth, driven by the increasing adoption of advanced medical technologies and the growing focus on improving patient outcomes.

Magnetic Resonance Imaging (MRI) Systems, Mixture Gas in the Global High Purity Medical Helium Market:

The usage of high purity medical helium in Magnetic Resonance Imaging (MRI) systems is one of the most critical applications in the healthcare industry. MRI systems rely on superconducting magnets to generate the strong magnetic fields necessary for producing detailed images of the human body. These superconducting magnets need to be cooled to extremely low temperatures to maintain their superconducting state, and liquid helium is the only substance capable of achieving these temperatures. The use of high purity liquid helium ensures that the MRI systems operate efficiently and reliably, providing accurate diagnostic images that are essential for detecting and monitoring various medical conditions. The purity of the helium is crucial in preventing contamination and ensuring the longevity of the MRI equipment. In addition to MRI systems, high purity helium gas is used in mixture gas applications, where it is combined with other gases for specific medical treatments. For example, helium-oxygen mixtures are used in respiratory therapies to help patients with breathing difficulties. The inert nature of helium makes it an ideal carrier gas, as it does not react with other substances and ensures the stability of the gas mixture. High purity helium gas is also used in gas chromatography, a technique used in medical laboratories to analyze complex mixtures of substances. The use of high purity helium in these applications ensures the accuracy and reliability of the results, which are critical for diagnosing and treating various medical conditions. The demand for high purity medical helium in these applications is driven by the increasing prevalence of respiratory diseases, advancements in medical diagnostics, and the growing need for precise and reliable medical treatments. The global high purity medical helium market plays a vital role in supporting these applications, providing the healthcare industry with the high-quality helium needed to ensure the safety and efficacy of medical treatments. The market is characterized by a focus on quality and purity, with suppliers and manufacturers investing in advanced technologies and processes to meet the stringent requirements of medical applications. As the healthcare industry continues to evolve and the demand for advanced medical technologies increases, the usage of high purity medical helium in MRI systems and mixture gas applications is expected to grow, driving the overall growth of the global high purity medical helium market.

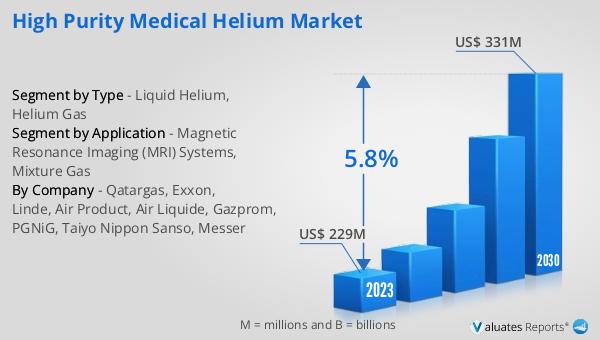

Global High Purity Medical Helium Market Outlook:

The global high purity medical helium market was valued at approximately $229 million in 2023 and is projected to reach around $331 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.8% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for high purity helium in various medical applications, driven by advancements in medical technology and the rising prevalence of chronic diseases. The market's expansion is supported by the continuous development of new medical devices and diagnostic tools that require high purity helium for optimal performance. The stringent quality standards and regulatory requirements governing the use of medical gases further emphasize the importance of high purity helium in ensuring the safety and efficacy of medical treatments. As the healthcare industry continues to advance, the demand for high purity medical helium is expected to grow, driven by the need for precise and reliable diagnostic and therapeutic technologies. The market outlook for high purity medical helium is positive, with significant growth opportunities anticipated in the coming years. The increasing adoption of advanced medical technologies, coupled with the growing focus on improving patient outcomes, is expected to drive the demand for high purity helium, supporting the overall growth of the global high purity medical helium market.

| Report Metric | Details |

| Report Name | High Purity Medical Helium Market |

| Accounted market size in 2023 | US$ 229 million |

| Forecasted market size in 2030 | US$ 331 million |

| CAGR | 5.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Qatargas, Exxon, Linde, Air Product, Air Liquide, Gazprom, PGNiG, Taiyo Nippon Sanso, Messer |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |