What is Global Polished Synthetic Diamond Market?

The Global Polished Synthetic Diamond Market refers to the industry focused on the production and sale of synthetic diamonds that have been polished to achieve a high-quality finish. Synthetic diamonds, also known as lab-grown or man-made diamonds, are created using advanced technological processes that replicate the natural conditions under which diamonds form. These diamonds are chemically, physically, and optically identical to natural diamonds but are produced in a controlled laboratory environment. The market for polished synthetic diamonds is driven by their various applications in industries such as jewelry, electronics, and healthcare. They offer a cost-effective and ethically sourced alternative to natural diamonds, which can be associated with environmental and ethical concerns. The market is expanding as technological advancements improve the quality and reduce the cost of synthetic diamonds, making them more accessible to a broader range of consumers and industries.

High-pressure, High-temperature, Chemical Vapor Deposition in the Global Polished Synthetic Diamond Market:

High-pressure, high-temperature (HPHT) and chemical vapor deposition (CVD) are the two primary methods used to produce synthetic diamonds in the Global Polished Synthetic Diamond Market. HPHT involves mimicking the natural conditions under which diamonds form by applying extreme pressure and temperature to carbon sources. This method typically uses a press to exert pressures of around 5-6 GPa and temperatures of 1,300-1,600 degrees Celsius. The carbon source, often graphite, is placed in a metal solvent, which facilitates the growth of diamond crystals. HPHT diamonds are known for their high quality and are often used in industrial applications due to their hardness and thermal conductivity. On the other hand, CVD involves breaking down carbon-containing gases, such as methane, in a vacuum chamber to deposit carbon atoms onto a substrate, forming a diamond layer. This process occurs at lower pressures and temperatures compared to HPHT, typically around 900-1,200 degrees Celsius. CVD allows for greater control over the diamond's properties, such as its size, shape, and purity, making it suitable for a wide range of applications, including electronics and optics. Both methods have their advantages and limitations, but together they enable the production of high-quality synthetic diamonds that meet the diverse needs of various industries. The choice between HPHT and CVD depends on the specific requirements of the application, such as the desired size, quality, and cost of the diamond. As technology continues to advance, these methods are becoming more efficient and cost-effective, further driving the growth of the Global Polished Synthetic Diamond Market.

Jewelry, Electronics, Healthcare, Others in the Global Polished Synthetic Diamond Market:

The Global Polished Synthetic Diamond Market finds extensive usage across various sectors, including jewelry, electronics, healthcare, and others. In the jewelry industry, synthetic diamonds are increasingly popular due to their ethical sourcing and affordability compared to natural diamonds. They offer the same brilliance and durability, making them an attractive option for consumers seeking high-quality, conflict-free gemstones. In the electronics sector, synthetic diamonds are valued for their exceptional thermal conductivity and electrical insulating properties. They are used in high-performance semiconductor devices, heat sinks, and optical components, where efficient heat dissipation is crucial. The healthcare industry also benefits from synthetic diamonds, particularly in medical devices and equipment. Their biocompatibility and hardness make them ideal for surgical tools, dental instruments, and even in certain types of implants. Additionally, synthetic diamonds are used in high-precision cutting and grinding tools, enhancing the performance and longevity of these instruments. Beyond these primary sectors, synthetic diamonds are also employed in research and development, particularly in the fields of quantum computing and high-energy physics, where their unique properties are leveraged for advanced scientific applications. The versatility and superior characteristics of synthetic diamonds make them a valuable resource across a wide range of industries, driving the growth and diversification of the Global Polished Synthetic Diamond Market.

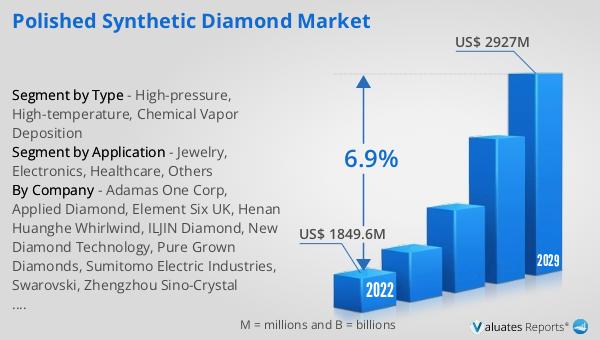

Global Polished Synthetic Diamond Market Outlook:

The Global Synthetic Diamond market is anticipated to grow significantly, with projections indicating it will reach approximately US$ 2,927 million by 2029, up from US$ 1,849.6 million in 2022. This growth represents a compound annual growth rate (CAGR) of 6.9% over the forecast period from 2023 to 2029. North America currently holds the largest market share, accounting for about 47% of the global market. This is followed by the Asia Pacific region, which holds a 36% market share. The substantial market share in North America can be attributed to the region's advanced technological infrastructure and high demand for synthetic diamonds in various applications, including industrial, electronics, and jewelry sectors. The Asia Pacific region's significant market share is driven by the rapid industrialization and increasing adoption of synthetic diamonds in emerging economies. The growing awareness of the benefits of synthetic diamonds, such as their ethical sourcing and cost-effectiveness, is also contributing to the market's expansion. As the demand for high-quality, sustainable alternatives to natural diamonds continues to rise, the Global Synthetic Diamond market is poised for robust growth in the coming years.

| Report Metric | Details |

| Report Name | Polished Synthetic Diamond Market |

| Accounted market size in 2022 | US$ 1849.6 million |

| Forecasted market size in 2029 | US$ 2927 million |

| CAGR | 6.9% |

| Base Year | 2022 |

| Forecasted years | 2024 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Adamas One Corp, Applied Diamond, Element Six UK, Henan Huanghe Whirlwind, ILJIN Diamond, New Diamond Technology, Pure Grown Diamonds, Sumitomo Electric Industries, Swarovski, Zhengzhou Sino-Crystal Diamond, Zhongnan Diamond |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |