What is Global Solid-state Battery Laser Equipment Market?

The Global Solid-state Battery Laser Equipment Market is an emerging sector that focuses on the development and application of laser technologies specifically designed for the production and enhancement of solid-state batteries. Solid-state batteries are a type of energy storage device that uses solid electrodes and a solid electrolyte, as opposed to the liquid or polymer gel electrolytes found in traditional lithium-ion or lithium polymer batteries. The laser equipment used in this market plays a crucial role in the manufacturing process, offering precision and efficiency that are essential for the production of high-quality solid-state batteries. These batteries are known for their potential to offer higher energy densities, improved safety, and longer life spans compared to their liquid-based counterparts. The market for solid-state battery laser equipment is driven by the increasing demand for advanced energy storage solutions across various industries, including automotive, consumer electronics, and renewable energy sectors. As the world moves towards more sustainable and efficient energy solutions, the role of laser technology in the production of solid-state batteries becomes increasingly significant, making this market a focal point for innovation and investment. The precision and adaptability of laser equipment make it indispensable in achieving the intricate designs and specifications required for next-generation battery technologies.

Laser Cutting Equipment, Laser Drying Equipment, Others in the Global Solid-state Battery Laser Equipment Market:

Laser Cutting Equipment, Laser Drying Equipment, and other related technologies form the backbone of the Global Solid-state Battery Laser Equipment Market. Laser Cutting Equipment is pivotal in the manufacturing process of solid-state batteries. It is used to precisely cut and shape the various components of the battery, such as electrodes and separators, ensuring that they fit perfectly within the battery casing. This precision is crucial because even the slightest deviation can affect the battery's performance and safety. The laser cutting process is highly efficient and can be automated, which reduces production time and costs. Moreover, it allows for the creation of complex designs that would be difficult or impossible to achieve with traditional cutting methods. On the other hand, Laser Drying Equipment is used to remove moisture from the battery components. Moisture can be detrimental to the performance and longevity of solid-state batteries, so it is essential to ensure that all components are thoroughly dried before assembly. Laser drying offers a non-contact method of drying, which reduces the risk of contamination and damage to the delicate components. It also provides uniform drying, which is critical for maintaining the integrity of the battery materials. In addition to cutting and drying, other laser technologies are employed in the solid-state battery manufacturing process. These include laser welding, which is used to join different components of the battery with high precision and strength. Laser welding is particularly important for creating strong and reliable connections between the battery cells and terminals. It also helps in minimizing the heat-affected zone, which can be a concern with traditional welding methods. Furthermore, laser marking is used to engrave important information, such as serial numbers and manufacturing dates, onto the battery components. This is essential for quality control and traceability, ensuring that each battery can be tracked throughout its lifecycle. The versatility of laser technology allows manufacturers to customize the production process to meet specific requirements, enhancing the overall quality and performance of the batteries. As the demand for solid-state batteries continues to grow, the role of laser equipment in their production becomes increasingly important. The ability to produce high-quality batteries efficiently and cost-effectively is a key factor driving the adoption of laser technologies in this market. Manufacturers are continually investing in research and development to improve the capabilities of laser equipment, making it more adaptable to the evolving needs of the solid-state battery industry. The integration of advanced laser technologies into the production process not only enhances the quality and performance of the batteries but also contributes to the overall sustainability of the manufacturing process by reducing waste and energy consumption. As a result, the Global Solid-state Battery Laser Equipment Market is poised for significant growth, driven by the increasing demand for advanced energy storage solutions and the continuous advancements in laser technology.

New Energy Vehicles, Consumer Electronics, Energy Storage Systems, Aerospace, Other in the Global Solid-state Battery Laser Equipment Market:

The Global Solid-state Battery Laser Equipment Market finds its applications across a wide range of industries, each benefiting from the unique advantages offered by solid-state batteries. In the realm of New Energy Vehicles (NEVs), solid-state batteries are seen as a game-changer. They offer higher energy densities, which translate to longer driving ranges for electric vehicles. The enhanced safety features of solid-state batteries, such as reduced risk of overheating and fire, make them an attractive option for automotive manufacturers. Laser equipment plays a crucial role in the production of these batteries, ensuring that they meet the stringent quality and safety standards required by the automotive industry. In Consumer Electronics, the demand for longer-lasting and safer batteries is ever-present. Solid-state batteries offer a solution to this demand, providing devices with extended battery life and improved safety. The precision and efficiency of laser equipment in manufacturing these batteries ensure that they are compact and lightweight, making them ideal for use in smartphones, laptops, and other portable devices. The Energy Storage Systems sector also benefits significantly from solid-state batteries. As the world shifts towards renewable energy sources, the need for efficient and reliable energy storage solutions becomes paramount. Solid-state batteries offer the potential for higher energy storage capacities and longer life spans, making them suitable for use in grid storage and backup power systems. Laser equipment is essential in the production of these batteries, ensuring that they are manufactured to the highest standards of quality and reliability. In the Aerospace industry, the demand for lightweight and high-performance batteries is critical. Solid-state batteries offer a solution to this demand, providing aircraft and spacecraft with the power they need while minimizing weight. The precision and adaptability of laser equipment in manufacturing these batteries ensure that they meet the rigorous standards required by the aerospace industry. Finally, other industries, such as medical devices and telecommunications, also benefit from the advantages offered by solid-state batteries. The ability to produce high-quality batteries efficiently and cost-effectively is a key factor driving the adoption of laser technologies in these sectors. As the demand for advanced energy storage solutions continues to grow, the role of the Global Solid-state Battery Laser Equipment Market in meeting this demand becomes increasingly important. The integration of advanced laser technologies into the production process not only enhances the quality and performance of the batteries but also contributes to the overall sustainability of the manufacturing process by reducing waste and energy consumption. As a result, the market is poised for significant growth, driven by the increasing demand for advanced energy storage solutions and the continuous advancements in laser technology.

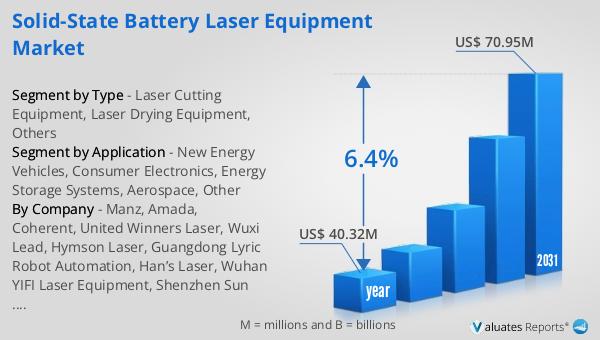

Global Solid-state Battery Laser Equipment Market Outlook:

The outlook for the Global Solid-state Battery Laser Equipment Market indicates a promising trajectory. In 2024, the market was valued at approximately US$ 40.32 million. This figure is expected to grow significantly, reaching an estimated size of US$ 70.95 million by the year 2031. This growth is projected to occur at a compound annual growth rate (CAGR) of 6.4% over the forecast period. This upward trend reflects the increasing demand for solid-state batteries across various industries, driven by their superior performance, safety, and longevity compared to traditional battery technologies. The role of laser equipment in the production of these batteries is crucial, as it ensures precision, efficiency, and quality in the manufacturing process. As industries such as automotive, consumer electronics, and renewable energy continue to seek advanced energy storage solutions, the demand for solid-state batteries and the laser equipment used in their production is expected to rise. The market's growth is also supported by ongoing research and development efforts aimed at improving the capabilities of laser technologies, making them more adaptable to the evolving needs of the solid-state battery industry. This focus on innovation and quality is essential for meeting the increasing demand for high-performance batteries, positioning the Global Solid-state Battery Laser Equipment Market for continued expansion in the coming years.

| Report Metric | Details |

| Report Name | Solid-state Battery Laser Equipment Market |

| Accounted market size in year | US$ 40.32 million |

| Forecasted market size in 2031 | US$ 70.95 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Manz, Amada, Coherent, United Winners Laser, Wuxi Lead, Hymson Laser, Guangdong Lyric Robot Automation, Han’s Laser, Wuhan YIFI Laser Equipment, Shenzhen Sun Laser Technology, Suzhou Delphi Laser, Shenzhen Yinghe Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |