What is Global Industrial Flaw Detection Film Market?

The Global Industrial Flaw Detection Film Market is a specialized segment within the broader non-destructive testing (NDT) industry. This market focuses on the production and distribution of films used to detect flaws in industrial materials and components. These films are crucial for ensuring the integrity and safety of various products and structures by identifying defects such as cracks, voids, and inclusions that may not be visible to the naked eye. The films are typically used in conjunction with radiographic testing methods, where they capture images of the internal structure of an object when exposed to radiation. The demand for flaw detection films is driven by the need for high-quality standards in industries such as aerospace, automotive, and construction, where safety and reliability are paramount. As industries continue to advance technologically, the need for precise and reliable flaw detection methods grows, making this market an essential component of quality assurance processes worldwide. The market is characterized by continuous innovation, with manufacturers striving to develop films that offer higher resolution, greater sensitivity, and improved environmental sustainability. This ongoing evolution ensures that the Global Industrial Flaw Detection Film Market remains a dynamic and vital part of the industrial landscape.

80mm×300mm, 80mm×360mm, 14in×17in, Others in the Global Industrial Flaw Detection Film Market:

In the Global Industrial Flaw Detection Film Market, various film sizes cater to different industrial needs, including 80mm×300mm, 80mm×360mm, 14in×17in, and others. Each size serves specific applications and industries, ensuring that the films can be effectively used in diverse testing scenarios. The 80mm×300mm films are often utilized in smaller, more intricate components where precision is crucial. These films are ideal for industries like electronics, where components are compact and require detailed inspection to ensure functionality and safety. The 80mm×360mm films, slightly larger, are suitable for medium-sized components, offering a balance between detail and coverage. This size is often used in automotive and aerospace industries, where components are larger but still require detailed inspection to detect any potential flaws that could compromise safety or performance. The 14in×17in films are among the largest standard sizes available and are used for inspecting large components or assemblies, such as those found in shipbuilding or large-scale manufacturing. These films provide extensive coverage, allowing for the inspection of large areas in a single exposure, which is crucial for efficiency in industries where time and accuracy are critical. Other sizes are also available to meet specific industry requirements, offering flexibility and adaptability to various testing environments. The choice of film size is influenced by factors such as the size of the component being inspected, the level of detail required, and the specific industry standards that must be met. Manufacturers in the Global Industrial Flaw Detection Film Market continuously innovate to provide films that meet the evolving needs of their customers, ensuring that they offer the right balance of size, sensitivity, and resolution for each application. This adaptability is essential for maintaining the integrity and safety of products across a wide range of industries, making flaw detection films an indispensable tool in quality assurance processes.

Electronic Components, Aerospace, Shipbuilding, Defense and Nuclear Industry, Automotive, Others in the Global Industrial Flaw Detection Film Market:

The Global Industrial Flaw Detection Film Market plays a crucial role in various industries, including electronic components, aerospace, shipbuilding, defense and nuclear industry, automotive, and others. In the electronic components industry, flaw detection films are used to inspect small, intricate parts such as circuit boards and microchips. These films help identify defects that could lead to malfunctions or failures, ensuring the reliability and performance of electronic devices. In the aerospace industry, flaw detection films are essential for inspecting critical components such as turbine blades, fuselage sections, and landing gear. These films help detect any structural weaknesses or defects that could compromise the safety and performance of aircraft. In shipbuilding, flaw detection films are used to inspect large metal structures, such as hulls and bulkheads, for cracks or other defects that could lead to structural failure. The defense and nuclear industry also relies heavily on flaw detection films to ensure the integrity of critical components and systems. These films are used to inspect everything from missile casings to nuclear reactor components, where even the smallest defect could have catastrophic consequences. In the automotive industry, flaw detection films are used to inspect components such as engine blocks, transmission systems, and suspension parts. These films help ensure that vehicles are safe and reliable, reducing the risk of accidents or breakdowns. Other industries, such as construction and manufacturing, also use flaw detection films to inspect a wide range of materials and components, ensuring that they meet the necessary quality and safety standards. The versatility and reliability of flaw detection films make them an indispensable tool in quality assurance processes across a wide range of industries, helping to ensure the safety and reliability of products and structures worldwide.

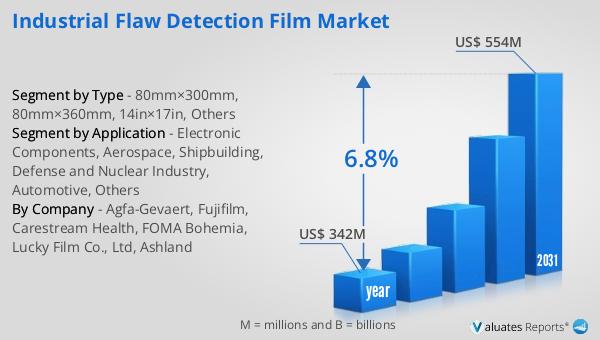

Global Industrial Flaw Detection Film Market Outlook:

The global market for Industrial Flaw Detection Film was valued at $342 million in 2024 and is expected to grow significantly, reaching an estimated $554 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.8% over the forecast period. The increasing demand for high-quality standards in various industries, such as aerospace, automotive, and construction, is driving this growth. As these industries continue to advance technologically, the need for precise and reliable flaw detection methods becomes more critical. The market is characterized by continuous innovation, with manufacturers striving to develop films that offer higher resolution, greater sensitivity, and improved environmental sustainability. This ongoing evolution ensures that the Global Industrial Flaw Detection Film Market remains a dynamic and vital part of the industrial landscape. The market's growth is also supported by the increasing adoption of non-destructive testing methods across various industries, as companies seek to improve their quality assurance processes and ensure the safety and reliability of their products. As a result, the Global Industrial Flaw Detection Film Market is expected to continue its upward trajectory, driven by the growing demand for high-quality standards and the ongoing development of innovative flaw detection solutions.

| Report Metric | Details |

| Report Name | Industrial Flaw Detection Film Market |

| Accounted market size in year | US$ 342 million |

| Forecasted market size in 2031 | US$ 554 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Agfa-Gevaert, Fujifilm, Carestream Health, FOMA Bohemia, Lucky Film Co., Ltd, Ashland |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |