What is Global Non-asbestos Brake Pads Market?

The Global Non-asbestos Brake Pads Market is a significant segment within the automotive industry, focusing on the production and distribution of brake pads that do not contain asbestos. Asbestos, once a common material in brake pads due to its heat resistance and durability, has been largely phased out due to health risks associated with its fibers. Non-asbestos brake pads are designed to offer similar performance without the associated health hazards. These brake pads are made from a variety of materials, including organic fibers, metals, and ceramics, each offering distinct advantages in terms of performance, durability, and cost. The market for these products is driven by increasing regulatory pressures to eliminate asbestos, growing awareness of health and environmental issues, and advancements in brake pad technology. As a result, manufacturers are investing in research and development to create innovative products that meet safety standards while providing optimal performance. The global market is characterized by a diverse range of products catering to different vehicle types and consumer preferences, making it a dynamic and competitive space. The demand for non-asbestos brake pads is expected to grow as more countries adopt stringent regulations and as consumers become more conscious of the benefits of safer, more sustainable automotive components.

Non-asbestos Organic Brake Pads, Metallic Formula Brake Pads, Ceramic Formula Brake Pads in the Global Non-asbestos Brake Pads Market:

Non-asbestos Organic (NAO) Brake Pads are a popular choice in the Global Non-asbestos Brake Pads Market due to their composition and performance characteristics. These brake pads are made from a blend of fibers, fillers, and binders, which are often organic in nature. The absence of asbestos makes them safer for both the environment and human health. NAO brake pads are known for their quiet operation and gentle impact on brake rotors, which can lead to longer rotor life. However, they may not perform as well under extreme conditions compared to other types of brake pads. Despite this, their cost-effectiveness and environmental benefits make them a preferred choice for many consumers, especially those who prioritize sustainability and noise reduction in urban driving conditions. Metallic Formula Brake Pads, on the other hand, are composed of a mixture of metals such as copper, iron, and steel, which are bonded together with a high-temperature resin. These brake pads are known for their durability and excellent performance in high-temperature situations, making them ideal for heavy-duty vehicles and performance cars. The metallic content allows for better heat dissipation, reducing the risk of brake fade during intense braking. However, they can be noisier and may cause more wear on brake rotors compared to organic pads. Despite these drawbacks, their superior stopping power and longevity make them a popular choice in the market. Ceramic Formula Brake Pads represent another significant segment within the Global Non-asbestos Brake Pads Market. These pads are made from a dense ceramic material, often combined with copper fibers, which helps in heat management and provides a stable friction coefficient. Ceramic brake pads are known for their quiet operation, low dust production, and consistent performance across a wide range of temperatures. They are less abrasive on rotors, which can extend the life of both the pads and the rotors. While ceramic pads tend to be more expensive than other types, their long lifespan and performance benefits often justify the higher cost for many consumers. In summary, the Global Non-asbestos Brake Pads Market offers a variety of options to meet different consumer needs and preferences. Non-asbestos Organic Brake Pads are favored for their environmental benefits and quiet operation, while Metallic Formula Brake Pads are chosen for their durability and high-performance capabilities. Ceramic Formula Brake Pads, with their low dust and consistent performance, provide a premium option for those willing to invest in long-term quality. Each type of brake pad has its own set of advantages and trade-offs, allowing consumers to select the best option based on their specific driving conditions and priorities.

OEM, Aftermarket in the Global Non-asbestos Brake Pads Market:

The Global Non-asbestos Brake Pads Market serves two primary areas: Original Equipment Manufacturer (OEM) and Aftermarket. In the OEM sector, non-asbestos brake pads are supplied directly to vehicle manufacturers for installation in new vehicles. This segment is driven by the automotive industry's shift towards safer and more environmentally friendly components. OEMs are increasingly adopting non-asbestos brake pads to comply with regulatory standards and to meet consumer demand for sustainable products. The use of non-asbestos brake pads in OEM applications ensures that new vehicles are equipped with components that offer reliable performance while minimizing health and environmental risks. This trend is particularly strong in regions with stringent environmental regulations, such as Europe and North America, where manufacturers are under pressure to reduce the environmental impact of their products. In the Aftermarket sector, non-asbestos brake pads are sold to consumers and repair shops for replacement purposes. This segment is characterized by a wide range of products catering to different vehicle types and consumer preferences. The aftermarket offers consumers the flexibility to choose brake pads that best suit their driving needs, whether they prioritize performance, cost, or environmental impact. The demand for non-asbestos brake pads in the aftermarket is driven by the growing awareness of the health risks associated with asbestos and the increasing availability of high-quality alternatives. Consumers are becoming more informed about the benefits of non-asbestos brake pads, leading to a shift in purchasing behavior towards safer and more sustainable options. Additionally, the aftermarket provides opportunities for innovation and differentiation, as manufacturers develop new formulations and technologies to enhance the performance and appeal of their products. Overall, the Global Non-asbestos Brake Pads Market plays a crucial role in both the OEM and Aftermarket sectors, providing essential components that contribute to vehicle safety and sustainability. The market's growth is supported by regulatory pressures, consumer awareness, and technological advancements, which together drive the adoption of non-asbestos brake pads across the automotive industry.

Global Non-asbestos Brake Pads Market Outlook:

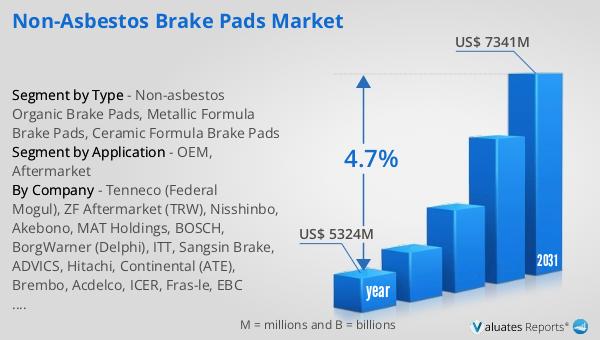

The outlook for the Global Non-asbestos Brake Pads Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 5,324 million. Looking ahead, it is anticipated to expand significantly, reaching an estimated size of US$ 7,341 million by the year 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.7% over the forecast period. The increasing demand for non-asbestos brake pads is driven by several factors, including heightened awareness of health and environmental concerns, regulatory mandates to eliminate asbestos from automotive components, and advancements in brake pad technology. As more countries implement stringent regulations to phase out asbestos, the market for non-asbestos alternatives is likely to experience sustained growth. Additionally, consumers are becoming more conscious of the benefits of using safer and more sustainable automotive components, further fueling demand. Manufacturers are responding to these trends by investing in research and development to create innovative products that meet safety standards while providing optimal performance. The competitive landscape of the market is characterized by a diverse range of products catering to different vehicle types and consumer preferences, making it a dynamic and evolving space. As the market continues to grow, it presents opportunities for manufacturers to differentiate themselves through innovation and quality, ultimately benefiting consumers with a wider array of choices.

| Report Metric | Details |

| Report Name | Non-asbestos Brake Pads Market |

| Accounted market size in year | US$ 5324 million |

| Forecasted market size in 2031 | US$ 7341 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tenneco (Federal Mogul), ZF Aftermarket (TRW), Nisshinbo, Akebono, MAT Holdings, BOSCH, BorgWarner (Delphi), ITT, Sangsin Brake, ADVICS, Hitachi, Continental (ATE), Brembo, Acdelco, ICER, Fras-le, EBC Brakes, ABS Friction, Shandong Gold Phoenix Co., Ltd., Shandong Xinyi Auto Parts Manufacturing Co., Ltd., Hunan Boyun Automobile Brake Materials Co., Ltd., Shandong Double Link Brake Material Co.,Ltd., AFI Brake Manufacturing Sdn. Bhd, TMD Friction |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |