What is Global FEP Peelable Heat Shrink Tubing Market?

The Global FEP Peelable Heat Shrink Tubing Market is a specialized segment within the broader heat shrink tubing industry, focusing on products made from Fluorinated Ethylene Propylene (FEP). This type of tubing is unique because it can be peeled away after shrinking, offering a convenient solution for applications requiring temporary insulation or protection. FEP peelable heat shrink tubing is known for its excellent chemical resistance, high-temperature performance, and non-stick properties, making it ideal for various industrial and medical applications. Its ability to withstand harsh environments while providing reliable insulation makes it a preferred choice in sectors like electronics, automotive, and healthcare. The market for this tubing is driven by the increasing demand for advanced materials that can meet stringent performance requirements in critical applications. As industries continue to innovate and develop new technologies, the need for high-quality, reliable materials like FEP peelable heat shrink tubing is expected to grow, further expanding the market's reach and potential. The versatility and efficiency of this product make it a valuable asset in numerous applications, contributing to its steady market growth.

1.3:1, 1.6:1, 2:1, Other in the Global FEP Peelable Heat Shrink Tubing Market:

In the Global FEP Peelable Heat Shrink Tubing Market, the ratios 1.3:1, 1.6:1, and 2:1 refer to the shrinkage ratios of the tubing. These ratios indicate how much the tubing will shrink in diameter when heat is applied. For instance, a 1.3:1 shrink ratio means that the tubing will shrink to 1.3 times its original size, while a 2:1 ratio means it will shrink to half its original diameter. Each ratio serves different purposes and applications, depending on the specific requirements of the task at hand. The 1.3:1 shrink ratio is typically used in applications where minimal shrinkage is needed, providing a snug fit without excessive compression. This ratio is often preferred in delicate applications where too much pressure could damage the underlying components. It is commonly used in electronics and electrical applications where precise insulation is required without altering the shape or integrity of the components. The 1.6:1 shrink ratio offers a bit more flexibility, allowing for a tighter fit while still maintaining the integrity of the components it covers. This ratio is suitable for applications where moderate shrinkage is needed to ensure a secure fit, such as in automotive and aerospace industries where components are subject to vibration and movement. The 2:1 shrink ratio is the most common and versatile, providing a significant reduction in diameter that ensures a tight, secure fit over a wide range of components. This ratio is ideal for applications where maximum shrinkage is needed to provide robust insulation and protection, such as in harsh environments or where components are exposed to extreme temperatures and chemicals. In addition to these standard ratios, other custom ratios are available to meet specific application needs. These custom ratios are designed to provide the exact level of shrinkage required for unique applications, ensuring optimal performance and protection. The choice of shrink ratio depends on several factors, including the size and shape of the components being covered, the environmental conditions they will be exposed to, and the level of protection required. By offering a range of shrink ratios, the Global FEP Peelable Heat Shrink Tubing Market caters to a wide variety of industries and applications, providing solutions that meet the diverse needs of its customers. The ability to choose the right shrink ratio for a specific application is crucial in ensuring the effectiveness and reliability of the tubing, making it an essential consideration for manufacturers and end-users alike.

Vascular Stents, Balloon Catheters, Interventional Devices, Other in the Global FEP Peelable Heat Shrink Tubing Market:

The Global FEP Peelable Heat Shrink Tubing Market finds extensive usage in the medical field, particularly in the production of vascular stents, balloon catheters, and interventional devices. In the case of vascular stents, FEP peelable heat shrink tubing is used to provide a temporary protective layer during the manufacturing process. The tubing's ability to withstand high temperatures and its chemical resistance make it ideal for use in the sterilization processes required for medical devices. Once the stent is ready for deployment, the tubing can be easily peeled away, leaving the stent intact and ready for use. This ensures that the stent remains free from contaminants and damage during production, enhancing its performance and reliability. Similarly, in the production of balloon catheters, FEP peelable heat shrink tubing is used to provide a protective layer during the manufacturing process. The tubing's non-stick properties ensure that it can be easily removed without leaving any residue, maintaining the integrity of the catheter. This is crucial in ensuring that the catheter functions correctly and safely when used in medical procedures. The tubing also provides insulation and protection during the sterilization process, ensuring that the catheter remains free from contaminants. In interventional devices, FEP peelable heat shrink tubing is used to provide insulation and protection during the manufacturing process. The tubing's ability to withstand high temperatures and its chemical resistance make it ideal for use in the production of devices that will be exposed to harsh environments. The tubing can be easily removed once the device is ready for use, ensuring that it remains free from contaminants and damage. This enhances the performance and reliability of the device, making it safer and more effective for use in medical procedures. In addition to these applications, FEP peelable heat shrink tubing is also used in other areas of the medical field, providing insulation and protection for a wide range of devices and components. Its versatility and reliability make it a valuable asset in the production of medical devices, contributing to the overall growth and success of the Global FEP Peelable Heat Shrink Tubing Market.

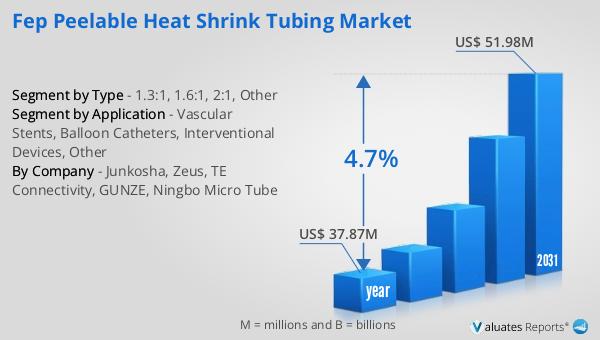

Global FEP Peelable Heat Shrink Tubing Market Outlook:

In 2024, the global market for FEP Peelable Heat Shrink Tubing was valued at approximately $37.87 million. This market is anticipated to experience growth over the coming years, with projections indicating that it will reach an estimated size of $51.98 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.7% during the forecast period. The steady increase in market size reflects the rising demand for FEP peelable heat shrink tubing across various industries, driven by its unique properties and versatile applications. The tubing's ability to provide reliable insulation and protection in harsh environments makes it a preferred choice for many manufacturers and end-users. As industries continue to innovate and develop new technologies, the need for high-quality, reliable materials like FEP peelable heat shrink tubing is expected to grow, further expanding the market's reach and potential. The market's growth is also supported by the increasing demand for advanced materials that can meet stringent performance requirements in critical applications. This demand is particularly strong in sectors like electronics, automotive, and healthcare, where the need for reliable insulation and protection is paramount. The versatility and efficiency of FEP peelable heat shrink tubing make it a valuable asset in numerous applications, contributing to its steady market growth. As the market continues to expand, manufacturers and suppliers are likely to invest in research and development to enhance the performance and capabilities of FEP peelable heat shrink tubing, ensuring that it remains a competitive and valuable product in the global market.

| Report Metric | Details |

| Report Name | FEP Peelable Heat Shrink Tubing Market |

| Accounted market size in year | US$ 37.87 million |

| Forecasted market size in 2031 | US$ 51.98 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Junkosha, Zeus, TE Connectivity, GUNZE, Ningbo Micro Tube |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |