What is Global Gas Turbine Forgings Market?

The Global Gas Turbine Forgings Market is a specialized segment within the broader industrial manufacturing sector, focusing on the production of forged components specifically designed for gas turbines. These turbines are critical in various industries, including power generation, aviation, and marine propulsion, due to their efficiency and reliability. Forging is a manufacturing process that involves shaping metal using localized compressive forces, and it is particularly suited for creating components that require high strength and durability. In the context of gas turbines, forgings are used to produce parts that can withstand extreme temperatures and pressures, ensuring the turbine's optimal performance and longevity. The market for gas turbine forgings is driven by the increasing demand for energy, advancements in turbine technology, and the need for efficient and environmentally friendly power generation solutions. As industries continue to seek ways to reduce emissions and improve energy efficiency, the demand for high-quality forged components in gas turbines is expected to grow. This market is characterized by a focus on innovation, quality, and precision, with manufacturers investing in advanced technologies and materials to meet the evolving needs of their customers.

Ring Forgings, Shaft Forgings, Blade Forgings, Others in the Global Gas Turbine Forgings Market:

In the Global Gas Turbine Forgings Market, several types of forgings play crucial roles, each serving specific functions within the turbine assembly. Ring forgings are essential components, often used in the construction of turbine casings and other circular parts. These rings are forged to withstand high rotational speeds and thermal stresses, ensuring the structural integrity of the turbine. The precision and strength of ring forgings are vital for maintaining the efficiency and safety of the turbine during operation. Shaft forgings, on the other hand, are critical for transmitting mechanical power within the turbine. These components must endure significant torsional forces and high temperatures, making their durability and precision crucial for the turbine's overall performance. The forging process enhances the mechanical properties of the shafts, providing the necessary strength and reliability. Blade forgings are perhaps the most intricate and vital components within a gas turbine. These blades are responsible for converting thermal energy into mechanical energy, driving the turbine's rotation. The design and material of blade forgings are critical, as they must withstand extreme temperatures and pressures while maintaining aerodynamic efficiency. Advanced materials and precision forging techniques are employed to produce blades that meet these demanding requirements. Other forgings in the gas turbine market include various ancillary components that support the turbine's operation. These may include discs, seals, and other structural parts that contribute to the turbine's overall functionality and efficiency. Each type of forging is tailored to meet specific performance criteria, ensuring that the gas turbine operates reliably and efficiently under challenging conditions. The development and production of these forgings require a deep understanding of materials science, engineering, and manufacturing processes, highlighting the complexity and sophistication of the Global Gas Turbine Forgings Market.

Power Generation, Ship, Oil and Gas, Others in the Global Gas Turbine Forgings Market:

The usage of Global Gas Turbine Forgings Market spans several key areas, each with unique requirements and applications. In power generation, gas turbines are a cornerstone technology, providing efficient and reliable electricity production. Forged components in these turbines are essential for ensuring high performance and longevity, as they must withstand the intense thermal and mechanical stresses encountered during operation. The precision and durability of forgings contribute to the overall efficiency of power plants, enabling them to meet the growing demand for clean and sustainable energy. In the maritime industry, gas turbines are used in ships for propulsion and power generation. The compact size and high power-to-weight ratio of gas turbines make them ideal for naval vessels and commercial ships. Forged components in marine gas turbines must endure harsh environmental conditions, including saltwater exposure and variable temperatures. The robustness and reliability of these forgings are critical for ensuring the safe and efficient operation of ships. In the oil and gas sector, gas turbines are employed for various applications, including pipeline compression and offshore platform power generation. The demanding conditions in this industry require forgings that can withstand corrosive environments and high pressures. The strength and resilience of forged components are vital for maintaining the integrity and performance of gas turbines in these challenging settings. Beyond these primary areas, gas turbine forgings are also used in other industries, such as aerospace and industrial manufacturing, where high-performance turbines are required for specialized applications. The versatility and adaptability of forged components make them indispensable in a wide range of sectors, highlighting the importance of the Global Gas Turbine Forgings Market in supporting modern industrial and technological advancements.

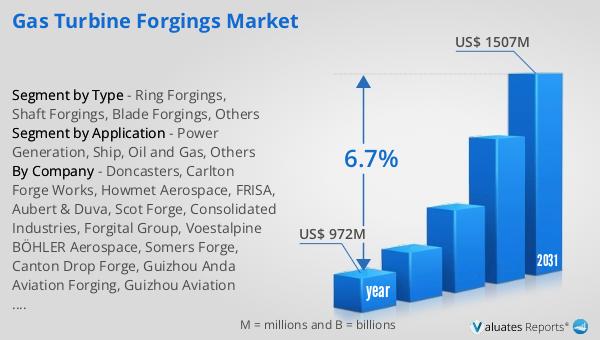

Global Gas Turbine Forgings Market Outlook:

The global market for Gas Turbine Forgings was valued at approximately $972 million in 2024, and it is anticipated to expand to a revised size of around $1,507 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.7% over the forecast period. This upward trajectory underscores the increasing demand for high-quality forged components in gas turbines, driven by the need for efficient and reliable power generation solutions across various industries. The market's expansion is fueled by advancements in turbine technology, the growing emphasis on reducing emissions, and the pursuit of sustainable energy sources. As industries continue to prioritize energy efficiency and environmental responsibility, the demand for durable and precision-engineered forgings is expected to rise. Manufacturers in the Global Gas Turbine Forgings Market are investing in innovative technologies and materials to meet these evolving demands, ensuring that their products remain at the forefront of industry standards. This market outlook highlights the critical role that gas turbine forgings play in supporting the global transition towards cleaner and more efficient energy systems, reflecting the broader trends and challenges facing the energy sector today.

| Report Metric | Details |

| Report Name | Gas Turbine Forgings Market |

| Accounted market size in year | US$ 972 million |

| Forecasted market size in 2031 | US$ 1507 million |

| CAGR | 6.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Doncasters, Carlton Forge Works, Howmet Aerospace, FRISA, Aubert & Duva, Scot Forge, Consolidated Industries, Forgital Group, Voestalpine BÖHLER Aerospace, Somers Forge, Canton Drop Forge, Guizhou Anda Aviation Forging, Guizhou Aviation Technical Development, SINOMACH, Wuxi Paike New Materials and Technology, Wuxi Hyatech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |