What is Global Elastic Monolithic Conveyor Belt Market?

The Global Elastic Monolithic Conveyor Belt Market refers to the industry focused on the production and distribution of conveyor belts that are made from a single, continuous piece of elastic material. These belts are designed to be seamless and are typically used in various industries for transporting goods and materials efficiently. Unlike traditional conveyor belts that may have seams or joints, elastic monolithic conveyor belts offer a smooth and uniform surface, which reduces the risk of contamination and makes them easier to clean. This feature is particularly important in industries such as food processing, pharmaceuticals, and packaging, where hygiene and cleanliness are paramount. The market for these conveyor belts is driven by the increasing demand for efficient and reliable material handling solutions across different sectors. Additionally, the durability and flexibility of these belts make them suitable for a wide range of applications, further boosting their popularity. As industries continue to seek ways to improve operational efficiency and reduce downtime, the demand for elastic monolithic conveyor belts is expected to grow, making it a significant segment within the broader conveyor belt market.

Thermoplastic Polyurethane (TPU), Polyurethane (PU) and Polyester Elastomers, Others in the Global Elastic Monolithic Conveyor Belt Market:

Thermoplastic Polyurethane (TPU), Polyurethane (PU), and Polyester Elastomers are key materials used in the manufacturing of elastic monolithic conveyor belts, each offering unique properties that cater to specific industrial needs. TPU is a highly versatile material known for its excellent abrasion resistance, flexibility, and durability. It is particularly favored in industries where conveyor belts are subjected to harsh conditions, such as heavy loads or abrasive materials. TPU belts are also resistant to oils, greases, and a variety of chemicals, making them ideal for use in environments where exposure to such substances is common. Additionally, TPU's elasticity allows for smooth operation and reduces the risk of belt slippage, ensuring efficient material handling. Polyurethane (PU) is another popular material used in the production of elastic monolithic conveyor belts. PU belts are known for their high tensile strength and resistance to wear and tear, making them suitable for applications that require long-lasting performance. They are also resistant to a wide range of temperatures, which makes them ideal for use in environments with fluctuating thermal conditions. PU belts are often used in the food industry due to their non-toxic nature and compliance with food safety standards. Their smooth surface prevents the accumulation of food particles, reducing the risk of contamination and ensuring hygienic operations. Polyester elastomers, on the other hand, offer a unique combination of flexibility and strength. These materials are known for their excellent resistance to stretching and deformation, which makes them ideal for applications where the conveyor belt needs to maintain its shape and integrity over long periods. Polyester elastomers are also resistant to a variety of chemicals and environmental factors, making them suitable for use in diverse industrial settings. Their ability to withstand high temperatures and maintain performance under stress makes them a preferred choice for industries such as automotive and logistics, where reliability and durability are crucial. In addition to these primary materials, other elastomers are also used in the production of elastic monolithic conveyor belts to cater to specific industrial requirements. These may include materials that offer enhanced resistance to specific chemicals or environmental conditions, or those that provide additional flexibility or strength. The choice of material often depends on the specific needs of the application, such as the type of materials being transported, the environmental conditions, and the desired lifespan of the conveyor belt. Overall, the use of Thermoplastic Polyurethane (TPU), Polyurethane (PU), and Polyester Elastomers in the Global Elastic Monolithic Conveyor Belt Market highlights the importance of material selection in ensuring the performance and reliability of conveyor systems. Each material offers distinct advantages that can be leveraged to meet the specific demands of different industries, making them integral to the development of efficient and effective material handling solutions. As industries continue to evolve and seek more advanced conveyor belt technologies, the role of these materials in the market is likely to remain significant, driving innovation and growth in the sector.

Food, Packaging, Pharmaceuticals, Logistics, Other in the Global Elastic Monolithic Conveyor Belt Market:

The Global Elastic Monolithic Conveyor Belt Market finds extensive usage across various industries, each benefiting from the unique properties of these conveyor belts. In the food industry, these belts are indispensable due to their seamless design and ease of cleaning, which are crucial for maintaining hygiene and preventing contamination. The belts are used in processing, packaging, and transporting food products, ensuring that they remain uncontaminated and safe for consumption. Their resistance to oils, fats, and other food-related substances further enhances their suitability for this industry, making them a preferred choice for food manufacturers worldwide. In the packaging industry, elastic monolithic conveyor belts play a vital role in streamlining operations and improving efficiency. These belts are used to transport packaged goods through various stages of the packaging process, from filling and sealing to labeling and boxing. Their durability and flexibility allow them to handle a wide range of packaging materials and sizes, ensuring smooth and uninterrupted operations. The belts' ability to withstand high speeds and heavy loads makes them ideal for high-volume packaging environments, where efficiency and reliability are paramount. The pharmaceutical industry also relies heavily on elastic monolithic conveyor belts for their operations. In this sector, the belts are used to transport pharmaceutical products through different stages of production, including mixing, filling, and packaging. The seamless design of these belts minimizes the risk of contamination, which is critical in maintaining the purity and efficacy of pharmaceutical products. Additionally, the belts' resistance to chemicals and ability to operate in sterile environments make them suitable for use in cleanrooms and other controlled settings, where maintaining strict hygiene standards is essential. In the logistics industry, elastic monolithic conveyor belts are used to facilitate the movement of goods within warehouses and distribution centers. These belts help streamline the sorting, loading, and unloading processes, improving overall efficiency and reducing handling times. Their ability to handle a wide range of products, from small packages to large parcels, makes them versatile and adaptable to various logistics operations. The belts' durability and low maintenance requirements also contribute to cost savings, making them an attractive option for logistics companies looking to optimize their operations. Beyond these industries, elastic monolithic conveyor belts are also used in other sectors, such as automotive, electronics, and textiles, where efficient material handling is crucial. In each of these areas, the belts' unique properties, such as their flexibility, durability, and resistance to various environmental factors, make them an essential component of modern manufacturing and distribution processes. As industries continue to evolve and seek more efficient and reliable material handling solutions, the demand for elastic monolithic conveyor belts is expected to grow, further solidifying their importance in the global market.

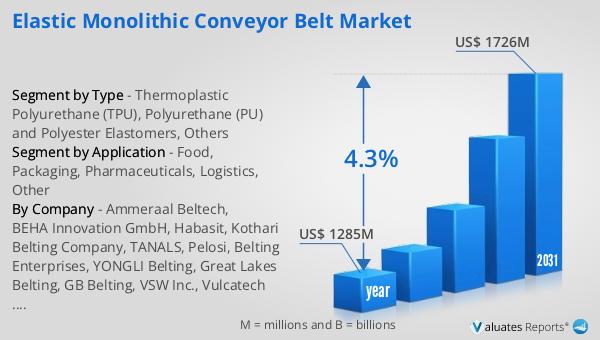

Global Elastic Monolithic Conveyor Belt Market Outlook:

In 2024, the global market for Elastic Monolithic Conveyor Belts was valued at approximately $1,285 million. Looking ahead, this market is anticipated to expand, reaching an estimated size of $1,726 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.3% over the forecast period. This steady increase in market size underscores the rising demand for these conveyor belts across various industries. The growth can be attributed to the belts' unique properties, such as their seamless design, durability, and flexibility, which make them suitable for a wide range of applications. Industries such as food processing, pharmaceuticals, packaging, and logistics are increasingly adopting these belts to enhance their operational efficiency and maintain high hygiene standards. As these industries continue to evolve and seek more advanced material handling solutions, the demand for elastic monolithic conveyor belts is expected to rise, driving market growth. This positive market outlook highlights the significant role that these conveyor belts play in modern industrial operations and their potential for continued expansion in the coming years.

| Report Metric | Details |

| Report Name | Elastic Monolithic Conveyor Belt Market |

| Accounted market size in year | US$ 1285 million |

| Forecasted market size in 2031 | US$ 1726 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ammeraal Beltech, BEHA Innovation GmbH, Habasit, Kothari Belting Company, TANALS, Pelosi, Belting Enterprises, YONGLI Belting, Great Lakes Belting, GB Belting, VSW Inc., Vulcatech Belting Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |