What is Global Dry Etching Machine Market?

The Global Dry Etching Machine Market is a crucial segment within the semiconductor manufacturing industry, focusing on the process of etching materials from the surface of semiconductor wafers. This market is driven by the increasing demand for miniaturized electronic devices, which require precise and efficient etching techniques. Dry etching machines utilize plasma or ionized gases to remove material, offering advantages such as high precision, better control over etching profiles, and reduced contamination compared to wet etching methods. These machines are essential in the production of integrated circuits, microelectromechanical systems (MEMS), and other semiconductor devices. The market is characterized by continuous technological advancements aimed at improving etching accuracy and efficiency, catering to the evolving needs of the electronics industry. As the demand for advanced electronic devices continues to grow, the Global Dry Etching Machine Market is expected to expand, driven by innovations in etching technology and the increasing complexity of semiconductor devices. The market's growth is also supported by the rising adoption of dry etching techniques in various applications, including logic and memory devices, power devices, and sensors, highlighting its significance in the semiconductor manufacturing landscape.

Conductor Etching, Dielectric Etching, Polysilicon Etching in the Global Dry Etching Machine Market:

Conductor etching, dielectric etching, and polysilicon etching are critical processes within the Global Dry Etching Machine Market, each serving distinct roles in semiconductor manufacturing. Conductor etching involves the removal of conductive materials, such as metals, from the wafer surface to create intricate circuit patterns. This process is essential for defining the electrical pathways in integrated circuits, ensuring that the devices function correctly. The precision of conductor etching is paramount, as any deviation can lead to circuit failures or reduced performance. Advanced dry etching machines are equipped with sophisticated control systems to achieve the necessary precision, making them indispensable in the production of high-performance electronic devices.

Logic and Memory, MEMS, Power Device, RFID, CMOS Image Sensors in the Global Dry Etching Machine Market:

Dielectric etching, on the other hand, focuses on removing insulating materials, such as silicon dioxide, from the wafer surface. This process is crucial for creating the necessary isolation between different components on a chip, preventing electrical interference and ensuring reliable device operation. Dielectric etching requires a high degree of accuracy to maintain the integrity of the insulating layers, which are often only a few nanometers thick. The use of dry etching techniques in this process offers several advantages, including reduced risk of contamination and the ability to etch complex patterns with high precision. As semiconductor devices become more complex, the demand for advanced dielectric etching solutions continues to grow, driving innovation in the Global Dry Etching Machine Market.

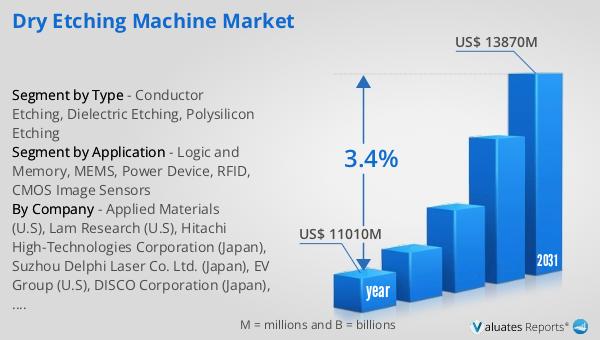

Global Dry Etching Machine Market Outlook:

Polysilicon etching is another vital process, primarily used in the fabrication of transistors and other semiconductor components. Polysilicon, a form of silicon with multiple small crystals, is commonly used as a gate material in metal-oxide-semiconductor field-effect transistors (MOSFETs). The etching of polysilicon requires precise control to ensure the correct dimensions and profiles of the gate structures, which directly impact the performance of the transistors. Dry etching machines are well-suited for this task, offering the precision and control needed to achieve the desired results. The continuous advancement of polysilicon etching techniques is essential for the development of smaller, more efficient semiconductor devices, further underscoring the importance of the Global Dry Etching Machine Market.

| Report Metric | Details |

| Report Name | Dry Etching Machine Market |

| Accounted market size in year | US$ 11010 million |

| Forecasted market size in 2031 | US$ 13870 million |

| CAGR | 3.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Applied Materials (U.S), Lam Research (U.S), Hitachi High-Technologies Corporation (Japan), Suzhou Delphi Laser Co. Ltd. (Japan), EV Group (U.S), DISCO Corporation (Japan), Plasma-Therm, LLC (U.S), Tokyo Electron Ltd. (Japan), Advanced Dicing Technologies (Israel), Panasonic Corporation (Japan) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |