What is Global Titanium Alloy Powder For 3D Printing Market?

The Global Titanium Alloy Powder for 3D Printing Market is a rapidly evolving sector that plays a crucial role in the advancement of additive manufacturing technologies. Titanium alloy powders are essential materials used in 3D printing, particularly for industries that require high-performance components with excellent strength-to-weight ratios. These powders are composed of titanium mixed with other elements to enhance their properties, making them ideal for creating complex and lightweight structures. The market for these powders is driven by the increasing demand for 3D printed parts in various industries such as aerospace, medical, automotive, and consumer electronics. The unique properties of titanium alloys, such as corrosion resistance, biocompatibility, and high strength, make them highly desirable for applications where traditional manufacturing methods fall short. As 3D printing technology continues to advance, the demand for high-quality titanium alloy powders is expected to grow, offering new opportunities for innovation and efficiency in manufacturing processes. The global market is characterized by ongoing research and development efforts aimed at improving powder quality, reducing costs, and expanding the range of applications for titanium alloy powders in 3D printing.

0-15um, 15-53um, 53-106um, 106-180um in the Global Titanium Alloy Powder For 3D Printing Market:

In the Global Titanium Alloy Powder for 3D Printing Market, the particle size of the powder is a critical factor that influences the quality and properties of the final printed product. The particle size distribution is categorized into different ranges, such as 0-15 micrometers (um), 15-53 um, 53-106 um, and 106-180 um, each serving specific applications and offering distinct advantages. The 0-15 um range is typically used for applications requiring high precision and fine detail, as smaller particles allow for smoother surface finishes and more intricate designs. This size range is particularly beneficial in industries like medical and aerospace, where precision and detail are paramount. The 15-53 um range is commonly used for general-purpose applications, offering a balance between detail and build speed. This range is versatile and can be used in a variety of industries, including automotive and consumer electronics, where both performance and efficiency are important. The 53-106 um range is often used for larger components that do not require as much detail but benefit from faster build times. This size range is suitable for applications where strength and durability are more critical than intricate details. Finally, the 106-180 um range is used for applications that require high build rates and are less concerned with surface finish quality. This range is ideal for producing large, robust parts quickly, making it suitable for industries like construction and heavy machinery. Each particle size range offers unique benefits and is chosen based on the specific requirements of the application, highlighting the versatility and adaptability of titanium alloy powders in 3D printing. The choice of particle size can significantly impact the mechanical properties, surface finish, and overall performance of the printed part, making it a crucial consideration in the additive manufacturing process. As the technology continues to evolve, manufacturers are exploring new ways to optimize particle size distribution to enhance the quality and efficiency of 3D printed components.

Aerospace and Defence, Medical, Consumer Electronics, Automotive, Other in the Global Titanium Alloy Powder For 3D Printing Market:

The usage of Global Titanium Alloy Powder for 3D Printing Market spans across various industries, each benefiting from the unique properties of titanium alloys. In the aerospace and defense sector, titanium alloy powders are used to produce lightweight, high-strength components that can withstand extreme conditions. The ability to create complex geometries with reduced material waste makes 3D printing an attractive option for manufacturing aircraft parts, such as engine components and structural elements. In the medical field, titanium alloy powders are used to create biocompatible implants and prosthetics. The precision and customization offered by 3D printing allow for the production of patient-specific implants that improve surgical outcomes and reduce recovery times. In consumer electronics, titanium alloy powders are used to produce lightweight and durable components for devices such as smartphones and laptops. The ability to create intricate designs with high precision makes 3D printing an ideal choice for producing components that require both aesthetic appeal and functional performance. In the automotive industry, titanium alloy powders are used to produce lightweight parts that improve fuel efficiency and performance. The ability to create complex shapes and reduce the weight of components without compromising strength is a significant advantage in automotive manufacturing. Other industries, such as construction and energy, also benefit from the use of titanium alloy powders in 3D printing. The versatility and adaptability of titanium alloys make them suitable for a wide range of applications, from producing large structural components to creating intricate designs for specialized equipment. As the demand for high-performance materials continues to grow, the use of titanium alloy powders in 3D printing is expected to expand, offering new opportunities for innovation and efficiency across various industries.

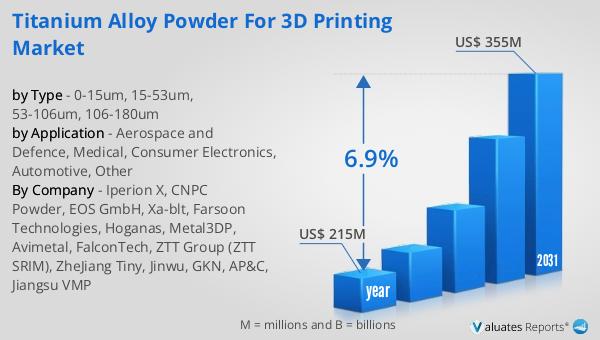

Global Titanium Alloy Powder For 3D Printing Market Outlook:

The global market for Titanium Alloy Powder for 3D Printing was valued at $215 million in 2024, with projections indicating it will reach a revised size of $355 million by 2031, growing at a compound annual growth rate (CAGR) of 6.9% during the forecast period. This growth reflects the increasing adoption of 3D printing technologies across various industries, driven by the need for high-performance materials that offer superior strength, durability, and lightweight properties. The market's expansion is fueled by ongoing advancements in additive manufacturing technologies, which enable the production of complex geometries and customized components with minimal material waste. As industries continue to seek innovative solutions to enhance efficiency and reduce costs, the demand for titanium alloy powders is expected to rise, offering new opportunities for manufacturers and suppliers in the market. The projected growth of the market underscores the importance of titanium alloy powders in the future of manufacturing, as they provide a critical material solution for industries looking to leverage the benefits of 3D printing. With continued research and development efforts focused on improving powder quality and expanding the range of applications, the global market for titanium alloy powders is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | Titanium Alloy Powder For 3D Printing Market |

| Accounted market size in year | US$ 215 million |

| Forecasted market size in 2031 | US$ 355 million |

| CAGR | 6.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Iperion X, CNPC Powder, EOS GmbH, Xa-blt, Farsoon Technologies, Hoganas, Metal3DP, Avimetal, FalconTech, ZTT Group (ZTT SRIM), ZheJiang Tiny, Jinwu, GKN, AP&C, Jiangsu VMP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |