What is Global Polyvinyl Butyral Emulsion Market?

The Global Polyvinyl Butyral (PVB) Emulsion Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of PVB emulsions. These emulsions are primarily used as binding agents due to their excellent adhesive properties, flexibility, and toughness. PVB emulsions are derived from polyvinyl butyral, a resin that is created through the reaction of polyvinyl alcohol with butyraldehyde. This market is driven by the demand for PVB emulsions in various applications such as automotive, construction, and electronics, where they are used in laminated safety glass, coatings, and films. The versatility of PVB emulsions makes them an essential component in industries that require materials with high durability and clarity. The market is characterized by continuous innovation and development to enhance the performance and application range of PVB emulsions, catering to the evolving needs of end-users. As industries increasingly prioritize safety and performance, the demand for PVB emulsions is expected to grow, making it a dynamic and competitive market. The global reach of this market is evident as it caters to diverse industries across different regions, adapting to local demands and regulations.

10% PVB Dispersions, 20% PVB Dispersions, 35% PVB Dispersions, Others in the Global Polyvinyl Butyral Emulsion Market:

In the Global Polyvinyl Butyral Emulsion Market, different concentrations of PVB dispersions are available, each serving specific purposes based on their properties. The 10% PVB dispersions are typically used in applications where a lower concentration of PVB is sufficient to achieve the desired adhesive or binding properties. These dispersions are often utilized in industries where cost-effectiveness is a priority, and the performance requirements are moderate. They provide a balance between performance and cost, making them suitable for applications such as basic coatings and adhesives. On the other hand, 20% PVB dispersions offer a higher concentration of PVB, providing enhanced adhesive properties and durability. These dispersions are preferred in applications that require a stronger bond and greater resistance to environmental factors such as moisture and temperature fluctuations. Industries such as automotive and construction often use 20% PVB dispersions for applications like laminated safety glass and high-performance coatings. The 35% PVB dispersions represent the highest concentration of PVB available in the market, offering superior adhesive strength and flexibility. These dispersions are used in demanding applications where maximum performance is required, such as in the production of high-strength laminated glass and advanced coatings that need to withstand extreme conditions. The high concentration of PVB in these dispersions ensures that they provide exceptional durability and resistance to wear and tear. Additionally, there are other specialized PVB dispersions available in the market, tailored to meet specific industry needs. These may include dispersions with additives that enhance certain properties such as UV resistance, chemical resistance, or flexibility. The availability of these specialized dispersions allows manufacturers to choose the most suitable product for their specific application, ensuring optimal performance and cost-effectiveness. The choice of PVB dispersion concentration depends on various factors, including the specific requirements of the application, environmental conditions, and cost considerations. Manufacturers and end-users must carefully evaluate these factors to select the appropriate PVB dispersion that meets their needs. The diversity of PVB dispersions in the market reflects the versatility and adaptability of PVB emulsions, catering to a wide range of industrial applications. As industries continue to evolve and demand more advanced materials, the development and innovation of PVB dispersions are expected to continue, providing new solutions and opportunities for growth in the Global Polyvinyl Butyral Emulsion Market.

Ink, Paint, Coating, Fabric, Other in the Global Polyvinyl Butyral Emulsion Market:

The Global Polyvinyl Butyral Emulsion Market finds extensive usage across various industries, including ink, paint, coating, fabric, and others, due to its unique properties. In the ink industry, PVB emulsions are used as binders to enhance the adhesion and durability of inks on different substrates. They provide excellent film-forming properties, ensuring that the ink adheres well to surfaces and remains vibrant and resistant to wear over time. This makes PVB emulsions a popular choice for printing applications where high-quality and long-lasting prints are required. In the paint industry, PVB emulsions are used to improve the flexibility, adhesion, and durability of paints. They help in forming a strong bond between the paint and the surface, ensuring that the paint remains intact and resistant to environmental factors such as moisture, UV radiation, and temperature changes. This makes PVB emulsions ideal for use in both interior and exterior paints, providing long-lasting protection and aesthetic appeal. In the coating industry, PVB emulsions are used to enhance the performance of coatings by providing excellent adhesion, flexibility, and resistance to environmental factors. They are used in a variety of applications, including automotive coatings, industrial coatings, and protective coatings, where durability and performance are critical. PVB emulsions help in forming a strong and flexible film that can withstand harsh conditions, ensuring that the coated surface remains protected and maintains its appearance over time. In the fabric industry, PVB emulsions are used as binders in textile coatings to improve the durability and performance of fabrics. They provide excellent adhesion and flexibility, ensuring that the coating remains intact and does not crack or peel over time. This makes PVB emulsions ideal for use in applications such as outdoor fabrics, upholstery, and technical textiles, where durability and performance are essential. Additionally, PVB emulsions are used in other industries such as construction, electronics, and packaging, where their unique properties are leveraged to enhance the performance and durability of products. In the construction industry, PVB emulsions are used in applications such as laminated safety glass and sealants, providing enhanced safety and performance. In the electronics industry, they are used in applications such as protective coatings and adhesives, ensuring the durability and reliability of electronic components. In the packaging industry, PVB emulsions are used to improve the adhesion and durability of packaging materials, ensuring that they remain intact and provide effective protection for the contents. The versatility and adaptability of PVB emulsions make them an essential component in a wide range of industrial applications, providing enhanced performance and durability.

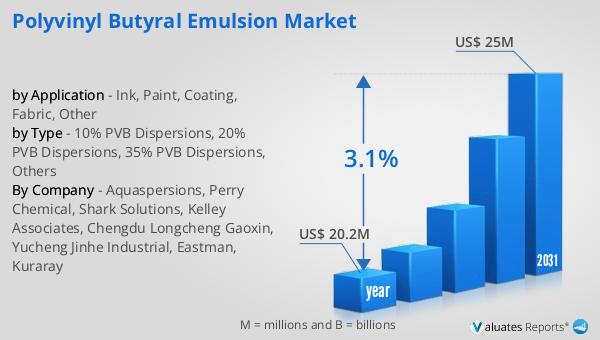

Global Polyvinyl Butyral Emulsion Market Outlook:

The global market for Polyvinyl Butyral Emulsion was valued at $20.2 million in 2024, with projections indicating it will grow to a revised size of $25 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.1% during the forecast period. Europe stands out as the largest market, accounting for approximately 41% of the global share. This dominance is attributed to the region's robust industrial base and the widespread adoption of PVB emulsions across various sectors such as automotive, construction, and electronics. The demand in Europe is driven by the need for high-performance materials that offer durability and safety, which are key attributes of PVB emulsions. The market's growth in this region is also supported by stringent regulations and standards that prioritize safety and environmental sustainability, further boosting the adoption of PVB emulsions. Following Europe, other regions are also witnessing significant growth in the PVB emulsion market, driven by increasing industrialization and the growing demand for advanced materials. The market's expansion is fueled by continuous innovation and development in PVB emulsion products, catering to the evolving needs of industries worldwide. As the market continues to grow, manufacturers are focusing on enhancing the performance and application range of PVB emulsions, ensuring they meet the diverse requirements of end-users across different regions. The global reach of the PVB emulsion market highlights its importance as a key component in various industrial applications, providing enhanced performance and durability.

| Report Metric | Details |

| Report Name | Polyvinyl Butyral Emulsion Market |

| Accounted market size in year | US$ 20.2 million |

| Forecasted market size in 2031 | US$ 25 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Aquaspersions, Perry Chemical, Shark Solutions, Kelley Associates, Chengdu Longcheng Gaoxin, Yucheng Jinhe Industrial, Eastman, Kuraray |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |