What is Global Holemaking Tool Market?

The Global Holemaking Tool Market is a dynamic and essential segment of the manufacturing industry, focusing on tools used to create holes in various materials. These tools are indispensable in numerous sectors, including automotive, aerospace, construction, and more, where precision and efficiency are paramount. The market encompasses a wide range of tools such as drill bits, reamers, and other specialized equipment designed to meet the diverse needs of different industries. The demand for holemaking tools is driven by the continuous advancements in manufacturing technologies and the increasing complexity of products that require precise and reliable holemaking solutions. As industries strive for higher productivity and quality, the need for advanced holemaking tools that offer durability, precision, and cost-effectiveness is on the rise. This market is characterized by innovation, with manufacturers constantly developing new materials and designs to enhance tool performance and lifespan. The global reach of this market is significant, with key players operating across various regions to cater to the growing demand. As industries continue to evolve, the Global Holemaking Tool Market is poised to play a crucial role in supporting the advancements in manufacturing processes worldwide.

Drill Bits, Reamers, Others in the Global Holemaking Tool Market:

Drill bits are a fundamental component of the Global Holemaking Tool Market, serving as the primary tool for creating holes in a variety of materials. These tools come in numerous shapes, sizes, and materials, each designed for specific applications and materials. High-speed steel (HSS) and carbide are among the most common materials used in the manufacturing of drill bits, offering a balance between durability and cost. Drill bits are used extensively in industries such as construction, automotive, and aerospace, where precision and efficiency are crucial. The design of a drill bit, including its tip angle and flute design, plays a significant role in its performance, influencing factors such as cutting speed, chip removal, and heat dissipation. Innovations in drill bit technology focus on enhancing these aspects to improve overall efficiency and lifespan. Reamers, on the other hand, are used to refine and enlarge existing holes, providing a smooth finish and precise dimensions. They are essential in applications where high precision is required, such as in the aerospace and automotive industries. Reamers are typically made from high-speed steel or carbide and are available in various designs, including straight and spiral flutes, to suit different materials and applications. The choice of reamer depends on factors such as the material being worked on, the desired finish, and the specific requirements of the application. Other tools in the holemaking market include countersinks, counterbores, and taps, each serving a unique purpose in the holemaking process. Countersinks are used to create a conical hole for a screw head to sit flush with or below the surface of the material, while counterbores are used to create a flat-bottomed hole for a bolt head or nut. Taps are used to create internal threads within a hole, allowing for the insertion of screws or bolts. These tools are critical in industries where assembly and fastening are integral parts of the manufacturing process. The Global Holemaking Tool Market is characterized by continuous innovation and development, with manufacturers focusing on creating tools that offer enhanced performance, durability, and cost-effectiveness. The use of advanced materials and coatings, such as titanium nitride and diamond-like carbon, is becoming increasingly common, providing tools with improved wear resistance and lifespan. As industries continue to demand higher precision and efficiency, the development of new and improved holemaking tools is expected to drive the growth of this market. The integration of digital technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), is also playing a significant role in the evolution of the holemaking tool market, enabling manufacturers to design and produce tools with greater precision and efficiency. Overall, the Global Holemaking Tool Market is a vital component of the manufacturing industry, providing the tools necessary for creating precise and reliable holes in a wide range of materials and applications.

Automotive, Architecture, Aerospace, Others in the Global Holemaking Tool Market:

The Global Holemaking Tool Market finds extensive usage across various industries, including automotive, architecture, aerospace, and others, each with its unique requirements and challenges. In the automotive industry, holemaking tools are crucial for manufacturing components such as engine blocks, transmission systems, and chassis parts. The demand for lightweight and fuel-efficient vehicles has led to the use of advanced materials such as aluminum and composites, which require specialized holemaking tools for efficient machining. Precision and efficiency are paramount in this industry, as even minor deviations can impact the performance and safety of the vehicle. In the architecture and construction industry, holemaking tools are used for drilling holes in materials such as concrete, steel, and wood. These tools are essential for tasks such as installing fixtures, creating openings for utilities, and assembling structural components. The durability and performance of holemaking tools are critical in this industry, as they must withstand the harsh conditions of construction sites and deliver consistent results. In the aerospace industry, the demand for high-precision holemaking tools is driven by the need for lightweight and high-performance components. Materials such as titanium and carbon fiber composites are commonly used in aerospace applications, requiring specialized tools that can handle their unique properties. The precision and reliability of holemaking tools are crucial in this industry, as they directly impact the safety and performance of aircraft. Other industries, such as electronics, medical devices, and energy, also rely on holemaking tools for various applications. In the electronics industry, for example, holemaking tools are used for drilling holes in printed circuit boards (PCBs) and other components. The miniaturization of electronic devices has increased the demand for high-precision tools that can create small and intricate holes with minimal deviation. In the medical device industry, holemaking tools are used for manufacturing components such as surgical instruments and implants, where precision and quality are of utmost importance. The energy industry, including oil and gas, also relies on holemaking tools for drilling and exploration activities. The harsh conditions and demanding requirements of this industry necessitate the use of robust and reliable tools that can withstand extreme environments. Overall, the Global Holemaking Tool Market plays a vital role in supporting the diverse needs of various industries, providing the tools necessary for creating precise and reliable holes in a wide range of materials and applications.

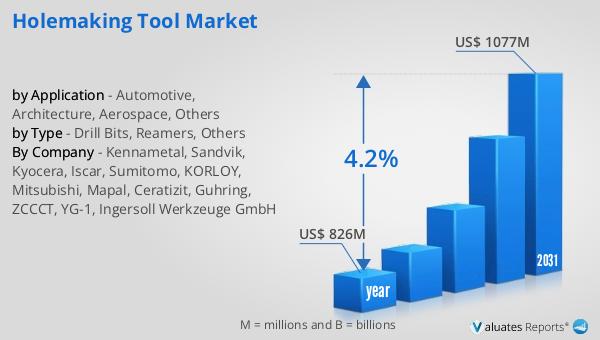

Global Holemaking Tool Market Outlook:

The global market for holemaking tools was valued at $826 million in 2024 and is expected to grow to a revised size of $1,077 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.2% during the forecast period. This growth is indicative of the increasing demand for advanced holemaking solutions across various industries. As manufacturing processes become more complex and the need for precision and efficiency rises, the demand for high-quality holemaking tools is expected to continue its upward trajectory. The market's expansion is driven by several factors, including technological advancements, the adoption of new materials, and the increasing complexity of products that require precise holemaking solutions. Manufacturers are focusing on developing innovative tools that offer enhanced performance, durability, and cost-effectiveness to meet the evolving needs of their customers. The integration of digital technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), is also playing a significant role in the evolution of the holemaking tool market, enabling manufacturers to design and produce tools with greater precision and efficiency. As industries continue to evolve and demand higher precision and efficiency, the Global Holemaking Tool Market is poised to play a crucial role in supporting the advancements in manufacturing processes worldwide.

| Report Metric | Details |

| Report Name | Holemaking Tool Market |

| Accounted market size in year | US$ 826 million |

| Forecasted market size in 2031 | US$ 1077 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kennametal, Sandvik, Kyocera, Iscar, Sumitomo, KORLOY, Mitsubishi, Mapal, Ceratizit, Guhring, ZCCCT, YG-1, Ingersoll Werkzeuge GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |