What is Global Exposed Fastening Panel Market?

The Global Exposed Fastening Panel Market is a significant segment within the construction and building materials industry. These panels are widely used for their durability, aesthetic appeal, and cost-effectiveness. Exposed fastening panels are characterized by their visible fasteners, which are used to attach the panels to the underlying structure. This type of panel is commonly used in both residential and commercial buildings, providing a sleek and modern look while ensuring structural integrity. The market for these panels is driven by the increasing demand for sustainable and energy-efficient building materials. As construction practices evolve, there is a growing emphasis on materials that offer both functionality and design flexibility. Exposed fastening panels meet these criteria, making them a popular choice among architects and builders. Additionally, advancements in manufacturing technologies have led to the development of panels with enhanced features such as improved weather resistance and thermal insulation. This has further fueled their adoption across various regions. The market is also influenced by trends in urbanization and infrastructure development, particularly in emerging economies where construction activities are on the rise. Overall, the Global Exposed Fastening Panel Market is poised for growth as it continues to adapt to the changing needs of the construction industry.

Galvanized Steel Material, Aluminum Material, Others in the Global Exposed Fastening Panel Market:

In the Global Exposed Fastening Panel Market, materials play a crucial role in determining the performance and application of the panels. Among the most commonly used materials are galvanized steel, aluminum, and other specialized materials. Galvanized steel is a popular choice due to its strength and corrosion resistance. It is made by coating steel with a layer of zinc, which protects the underlying metal from rust and environmental damage. This makes galvanized steel panels ideal for use in harsh weather conditions and industrial environments. They are often used in roofing and siding applications where durability is a priority. Aluminum, on the other hand, is valued for its lightweight properties and resistance to corrosion. It is an excellent choice for projects where weight is a concern, such as in high-rise buildings or structures with specific load-bearing requirements. Aluminum panels are also highly versatile and can be easily shaped and colored to meet aesthetic demands. This makes them a preferred option for architects looking to create visually striking designs. In addition to galvanized steel and aluminum, the market also includes panels made from other materials such as copper, zinc, and composite materials. Copper panels are known for their unique appearance and natural patina, which develops over time, adding character to the building. Zinc panels offer similar aesthetic benefits and are also highly durable and recyclable, making them an environmentally friendly option. Composite materials, which combine different elements to enhance specific properties, are gaining popularity for their ability to offer tailored solutions for various construction needs. These materials can provide improved thermal insulation, soundproofing, and fire resistance, making them suitable for a wide range of applications. The choice of material in the Global Exposed Fastening Panel Market is often influenced by factors such as cost, environmental conditions, and design requirements. As the market continues to evolve, manufacturers are investing in research and development to create innovative materials that meet the growing demand for sustainable and high-performance building solutions.

Roof, Wall, Others in the Global Exposed Fastening Panel Market:

The Global Exposed Fastening Panel Market finds extensive usage in various areas, including roofs, walls, and other applications. In roofing, exposed fastening panels are favored for their ability to provide a durable and weather-resistant covering. They are designed to withstand extreme weather conditions, including heavy rain, snow, and high winds, making them a reliable choice for protecting buildings. The visible fasteners not only contribute to the structural integrity of the roof but also add a distinctive aesthetic element. These panels are available in a range of materials and finishes, allowing for customization to suit different architectural styles. In wall applications, exposed fastening panels offer both functional and decorative benefits. They serve as an effective barrier against environmental elements while enhancing the visual appeal of the building. The panels can be installed vertically or horizontally, providing flexibility in design. They are often used in commercial and industrial buildings where a modern and professional appearance is desired. The ease of installation and maintenance further adds to their appeal, making them a cost-effective solution for wall cladding. Beyond roofs and walls, exposed fastening panels are also used in other areas such as facades, canopies, and interior partitions. In facade applications, they contribute to the building's overall energy efficiency by providing insulation and reducing thermal bridging. Canopies and awnings made from these panels offer protection from the elements while complementing the building's exterior design. Inside buildings, exposed fastening panels can be used to create partitions and dividers, offering a contemporary look and feel. The versatility of these panels makes them suitable for a wide range of projects, from residential homes to large commercial complexes. As the demand for sustainable and aesthetically pleasing building materials continues to grow, the usage of exposed fastening panels is expected to expand across various sectors.

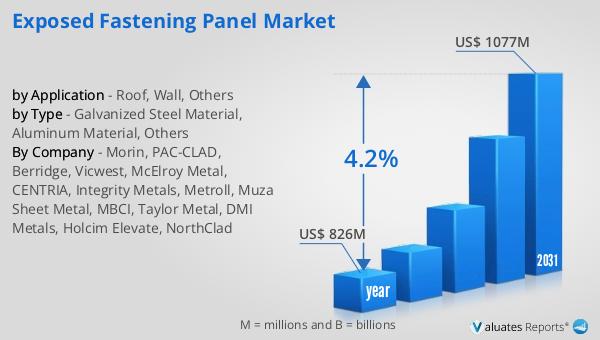

Global Exposed Fastening Panel Market Outlook:

The outlook for the Global Exposed Fastening Panel Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 826 million. By 2031, it is anticipated to reach a revised size of around US$ 1077 million, reflecting a compound annual growth rate (CAGR) of 4.2% over the forecast period. This growth can be attributed to several factors, including the increasing demand for durable and aesthetically appealing building materials. As construction activities continue to rise globally, particularly in emerging economies, the need for efficient and cost-effective solutions like exposed fastening panels is becoming more pronounced. These panels offer a unique combination of functionality and design flexibility, making them a preferred choice for architects and builders. Additionally, advancements in manufacturing technologies are enabling the production of panels with enhanced features, such as improved weather resistance and thermal insulation. This is further driving their adoption across various regions. The market is also benefiting from the growing trend towards sustainable construction practices, as exposed fastening panels are often made from recyclable materials and contribute to energy efficiency. Overall, the Global Exposed Fastening Panel Market is poised for steady growth as it continues to adapt to the evolving needs of the construction industry.

| Report Metric | Details |

| Report Name | Exposed Fastening Panel Market |

| Accounted market size in year | US$ 826 million |

| Forecasted market size in 2031 | US$ 1077 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Morin, PAC-CLAD, Berridge, Vicwest, McElroy Metal, CENTRIA, Integrity Metals, Metroll, Muza Sheet Metal, MBCI, Taylor Metal, DMI Metals, Holcim Elevate, NorthClad |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |