What is Global Fixed Welding Fume Extractor Market?

The Global Fixed Welding Fume Extractor Market is a specialized segment within the industrial equipment industry, focusing on devices designed to remove harmful fumes generated during welding processes. These extractors are crucial for maintaining a safe and healthy working environment, as welding fumes can contain hazardous substances like metal oxides and gases that pose health risks to workers. Fixed welding fume extractors are permanently installed systems that provide continuous air filtration and purification in welding areas. They are particularly beneficial in large-scale industrial settings where welding is a constant activity, such as in automotive manufacturing, shipbuilding, and construction. The market for these extractors is driven by stringent occupational safety regulations and the growing awareness of workplace health hazards. As industries continue to prioritize worker safety and environmental compliance, the demand for efficient and reliable fume extraction solutions is expected to rise. These systems not only help in reducing health risks but also enhance productivity by ensuring a cleaner and more comfortable working environment. The market is characterized by technological advancements, with manufacturers focusing on developing more efficient and user-friendly systems to meet the evolving needs of various industries.

Automatic Cleaning, Manual Cleaning in the Global Fixed Welding Fume Extractor Market:

In the Global Fixed Welding Fume Extractor Market, cleaning mechanisms play a crucial role in maintaining the efficiency and longevity of the equipment. There are primarily two types of cleaning methods employed: automatic cleaning and manual cleaning. Automatic cleaning systems are designed to operate with minimal human intervention, using mechanisms such as pulse jet cleaning, which utilizes bursts of compressed air to dislodge and remove accumulated dust and particulates from the filter media. This method is highly efficient and ensures that the extractor operates at optimal performance levels with minimal downtime. Automatic cleaning systems are particularly advantageous in large-scale industrial settings where continuous operation is required, as they reduce the need for manual labor and increase the overall productivity of the welding process. On the other hand, manual cleaning systems require human intervention to clean and maintain the filters. This typically involves removing the filters from the extractor and manually cleaning them, either by shaking, washing, or using compressed air. While manual cleaning systems may be more cost-effective initially, they can lead to increased downtime and labor costs over time, as they require regular maintenance and attention. Additionally, manual cleaning may not be as thorough as automatic systems, potentially leading to reduced efficiency and increased wear and tear on the equipment. In the context of the Global Fixed Welding Fume Extractor Market, the choice between automatic and manual cleaning systems often depends on the specific needs and budget constraints of the end-user. Industries with high-volume welding operations may prefer automatic systems for their efficiency and reduced labor requirements, while smaller operations may opt for manual systems due to their lower initial cost. However, as technology advances and the cost of automatic systems decreases, there is a growing trend towards the adoption of automatic cleaning systems across various industries. This shift is driven by the need for more efficient and reliable fume extraction solutions that can keep up with the demands of modern industrial operations. Furthermore, the integration of smart technologies and IoT in automatic cleaning systems is enhancing their capabilities, allowing for real-time monitoring and predictive maintenance, which further reduces downtime and operational costs. As the Global Fixed Welding Fume Extractor Market continues to evolve, the demand for advanced cleaning systems is expected to grow, driven by the increasing emphasis on workplace safety and environmental compliance. Manufacturers are focusing on developing innovative solutions that offer a balance between cost, efficiency, and ease of use, catering to the diverse needs of industries worldwide.

Arc Welding, Resistance Welding, Laser Beam Welding, Oxy Fuel Welding, Robot Welding in the Global Fixed Welding Fume Extractor Market:

The Global Fixed Welding Fume Extractor Market finds its application across various welding processes, each with its unique requirements and challenges. In arc welding, which is one of the most common welding methods, the use of fixed fume extractors is essential due to the significant amount of fumes and gases produced. Arc welding involves the use of an electric arc to melt and join metals, generating fumes that can contain harmful substances like manganese and hexavalent chromium. Fixed fume extractors help in capturing these fumes at the source, ensuring a safer working environment for welders. Resistance welding, another widely used process, involves the application of pressure and electric current to join metals. Although it produces fewer fumes compared to arc welding, the use of fume extractors is still important to capture any emissions and maintain air quality. Laser beam welding, known for its precision and speed, generates fumes that can be effectively managed with fixed fume extractors. These systems are designed to handle the high temperatures and concentrated emissions associated with laser welding, ensuring that the work area remains free from harmful particulates. Oxy-fuel welding, which uses a combination of oxygen and fuel gases to weld and cut metals, produces a significant amount of smoke and fumes. Fixed fume extractors are crucial in this process to remove the dense smoke and maintain visibility and air quality in the workspace. Lastly, robot welding, which is increasingly being adopted in industries for its efficiency and precision, also benefits from the use of fixed fume extractors. These systems are integrated into robotic welding cells to ensure that the fumes generated during the automated welding process are effectively captured and filtered. The use of fixed fume extractors in these various welding processes not only enhances worker safety but also contributes to compliance with occupational health and safety regulations. By providing a cleaner and healthier working environment, these systems help in reducing the risk of respiratory issues and other health problems associated with prolonged exposure to welding fumes. As industries continue to adopt advanced welding technologies, the demand for efficient fume extraction solutions is expected to grow, driving innovation and development in the Global Fixed Welding Fume Extractor Market.

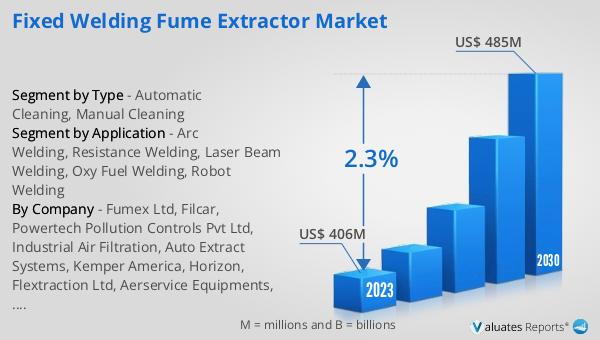

Global Fixed Welding Fume Extractor Market Outlook:

The outlook for the Global Fixed Welding Fume Extractor Market indicates a steady growth trajectory over the coming years. In 2024, the market was valued at approximately $432 million, reflecting the increasing demand for effective fume extraction solutions in various industries. By 2031, the market is projected to expand to a revised size of $505 million, driven by a compound annual growth rate (CAGR) of 2.3% during the forecast period. This growth can be attributed to several factors, including the rising awareness of occupational health and safety, stringent regulatory requirements, and the continuous advancements in fume extraction technologies. As industries prioritize worker safety and environmental compliance, the adoption of fixed welding fume extractors is expected to increase, contributing to the market's expansion. Additionally, the integration of smart technologies and IoT in fume extraction systems is enhancing their efficiency and capabilities, further driving their adoption across various sectors. The market's growth is also supported by the increasing demand for automated and efficient fume extraction solutions that can keep up with the demands of modern industrial operations. As the Global Fixed Welding Fume Extractor Market continues to evolve, manufacturers are focusing on developing innovative solutions that offer a balance between cost, efficiency, and ease of use, catering to the diverse needs of industries worldwide.

| Report Metric | Details |

| Report Name | Fixed Welding Fume Extractor Market |

| Accounted market size in year | US$ 432 million |

| Forecasted market size in 2031 | US$ 505 million |

| CAGR | 2.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fumex Ltd, Filcar, Powertech Pollution Controls Pvt Ltd, Industrial Air Filtration, Auto Extract Systems, Kemper America, Horizon, Flextraction Ltd, Aerservice Equipments, Plymovent |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |