What is Global Automatic Wafer Bonder Market?

The Global Automatic Wafer Bonder Market is a specialized segment within the semiconductor equipment industry, focusing on the development and sale of machines that bond wafers together. These machines are crucial in the manufacturing of semiconductors, where precision and reliability are paramount. Wafer bonding is a process that involves joining two or more wafers to create a single, unified structure, which is essential in the production of various electronic components. The market for automatic wafer bonders is driven by the increasing demand for miniaturized electronic devices, advancements in semiconductor technology, and the need for high-performance computing solutions. As industries such as consumer electronics, automotive, and telecommunications continue to grow, the demand for efficient and reliable wafer bonding solutions is expected to rise. The market is characterized by technological innovations, with manufacturers focusing on enhancing the speed, accuracy, and automation capabilities of their machines. This market is also influenced by the global push towards more sustainable and energy-efficient manufacturing processes, which has led to the development of eco-friendly wafer bonding technologies. Overall, the Global Automatic Wafer Bonder Market plays a critical role in the advancement of semiconductor manufacturing, supporting the production of cutting-edge electronic devices.

Semi-Automated Wafer Bonder, Fully-Automated Wafer Bonder in the Global Automatic Wafer Bonder Market:

In the realm of the Global Automatic Wafer Bonder Market, two primary types of machines are prevalent: Semi-Automated Wafer Bonders and Fully-Automated Wafer Bonders. Semi-Automated Wafer Bonders are designed to offer a balance between manual intervention and automation. These machines require some level of human oversight and intervention during the bonding process, making them suitable for applications where flexibility and customization are needed. They are often used in research and development settings or in production environments where small to medium batch sizes are common. The semi-automated systems allow operators to adjust parameters and settings to meet specific bonding requirements, providing a level of control that is not always possible with fully automated systems. On the other hand, Fully-Automated Wafer Bonders are designed for high-volume production environments where consistency, speed, and efficiency are critical. These machines operate with minimal human intervention, utilizing advanced robotics and software to perform the bonding process with precision and repeatability. Fully-automated systems are ideal for large-scale manufacturing operations where the demand for uniformity and throughput is high. They are equipped with sophisticated sensors and control systems that ensure optimal bonding conditions, reducing the risk of defects and improving overall yield. The choice between semi-automated and fully-automated wafer bonders depends on several factors, including production volume, budget, and specific application requirements. Companies must carefully evaluate their needs and capabilities to select the appropriate type of wafer bonder that aligns with their operational goals. As the semiconductor industry continues to evolve, the demand for both semi-automated and fully-automated wafer bonders is expected to grow, driven by the increasing complexity of electronic devices and the need for more efficient manufacturing processes. Manufacturers in the Global Automatic Wafer Bonder Market are continually innovating to enhance the performance and capabilities of their machines, ensuring they meet the ever-changing demands of the industry. This ongoing innovation is crucial for maintaining competitiveness and addressing the diverse needs of customers across various sectors.

MEMS, Advanced Packaging, CIS, Others in the Global Automatic Wafer Bonder Market:

The Global Automatic Wafer Bonder Market finds its application in several key areas, including MEMS (Micro-Electro-Mechanical Systems), Advanced Packaging, CIS (CMOS Image Sensors), and other sectors. In the MEMS sector, wafer bonding is a critical process used to create complex microstructures that are essential for the functionality of MEMS devices. These devices are used in a wide range of applications, from automotive sensors to consumer electronics, and require precise and reliable bonding techniques to ensure their performance and durability. The demand for MEMS devices is growing rapidly, driven by the increasing adoption of smart technologies and the Internet of Things (IoT), which in turn fuels the need for advanced wafer bonding solutions. In the field of Advanced Packaging, wafer bonding plays a vital role in the development of innovative packaging solutions that enhance the performance and efficiency of semiconductor devices. Advanced packaging techniques, such as 3D stacking and system-in-package (SiP), rely on wafer bonding to achieve the necessary interconnections and integration of multiple components. This is crucial for meeting the demands of high-performance computing, telecommunications, and other industries that require compact and powerful electronic devices. The CIS sector also benefits significantly from the Global Automatic Wafer Bonder Market, as wafer bonding is used to produce high-quality image sensors that are integral to digital cameras, smartphones, and other imaging devices. The demand for CIS is driven by the growing popularity of high-resolution cameras and the increasing use of imaging technology in various applications, from security systems to medical imaging. Other sectors that utilize wafer bonding include the production of power devices, RF components, and optoelectronic devices, all of which require precise and reliable bonding techniques to ensure their functionality and performance. As these industries continue to expand and evolve, the demand for advanced wafer bonding solutions is expected to increase, driving growth in the Global Automatic Wafer Bonder Market. Manufacturers are continually developing new technologies and processes to meet the diverse needs of these sectors, ensuring they remain competitive and capable of addressing the challenges of modern semiconductor manufacturing.

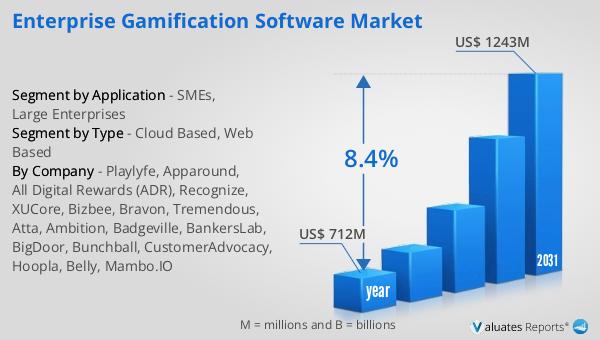

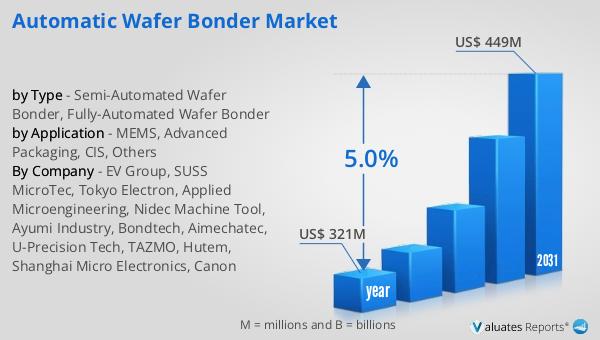

Global Automatic Wafer Bonder Market Outlook:

The global market for Automatic Wafer Bonder was valued at $321 million in 2024, with projections indicating a growth to $449 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.0% over the forecast period. The market's expansion is driven by several factors, including the increasing demand for advanced semiconductor devices, the rise of smart technologies, and the need for more efficient manufacturing processes. As industries such as consumer electronics, automotive, and telecommunications continue to grow, the demand for reliable and efficient wafer bonding solutions is expected to rise. The market is characterized by technological innovations, with manufacturers focusing on enhancing the speed, accuracy, and automation capabilities of their machines. This ongoing innovation is crucial for maintaining competitiveness and addressing the diverse needs of customers across various sectors. The market's growth is also influenced by the global push towards more sustainable and energy-efficient manufacturing processes, which has led to the development of eco-friendly wafer bonding technologies. Overall, the Global Automatic Wafer Bonder Market plays a critical role in the advancement of semiconductor manufacturing, supporting the production of cutting-edge electronic devices.

| Report Metric | Details |

| Report Name | Automatic Wafer Bonder Market |

| Accounted market size in year | US$ 321 million |

| Forecasted market size in 2031 | US$ 449 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | EV Group, SUSS MicroTec, Tokyo Electron, Applied Microengineering, Nidec Machine Tool, Ayumi Industry, Bondtech, Aimechatec, U-Precision Tech, TAZMO, Hutem, Shanghai Micro Electronics, Canon |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |