What is Global Wafer Heaters Market?

The Global Wafer Heaters Market is a specialized segment within the semiconductor industry, focusing on devices that provide precise temperature control during the manufacturing of semiconductor wafers. These heaters are critical in processes such as deposition, etching, and annealing, where maintaining a consistent temperature is essential for ensuring the quality and performance of the final semiconductor products. Wafer heaters are designed to withstand high temperatures and corrosive environments, making them indispensable in cleanroom settings where semiconductor fabrication occurs. The market for wafer heaters is driven by the increasing demand for semiconductors in various applications, including consumer electronics, automotive, and telecommunications. As technology advances, the need for more sophisticated and efficient wafer heaters grows, pushing manufacturers to innovate and improve their products. The market is characterized by a mix of established players and new entrants, each striving to offer solutions that meet the evolving needs of semiconductor manufacturers. With the ongoing expansion of the semiconductor industry, the Global Wafer Heaters Market is poised for significant growth, reflecting the critical role these devices play in the production of advanced electronic components.

Metal Heaters, Ceramic Heaters in the Global Wafer Heaters Market:

Metal heaters and ceramic heaters are two primary types of wafer heaters used in the Global Wafer Heaters Market, each offering distinct advantages and applications. Metal heaters, typically made from materials like aluminum or stainless steel, are known for their durability and excellent thermal conductivity. These heaters are often used in applications where rapid heating and cooling cycles are required, as they can quickly reach the desired temperature and maintain it with precision. Metal heaters are also favored for their robustness, making them suitable for harsh environments where mechanical stress and chemical exposure are common. On the other hand, ceramic heaters are prized for their superior thermal insulation properties and ability to operate at higher temperatures than metal heaters. Made from advanced ceramic materials, these heaters provide uniform heat distribution, which is crucial for processes that demand high precision and consistency. Ceramic heaters are often used in applications where temperature stability and uniformity are paramount, such as in chemical vapor deposition (CVD) and physical vapor deposition (PVD) processes. The choice between metal and ceramic heaters depends largely on the specific requirements of the application, including factors like temperature range, heating rate, and environmental conditions. In the Global Wafer Heaters Market, ceramic heaters have gained popularity due to their versatility and efficiency, capturing a significant share of the market. This preference is driven by the increasing complexity of semiconductor manufacturing processes, which demand heaters that can deliver precise temperature control and uniformity. As the semiconductor industry continues to evolve, both metal and ceramic heaters will play crucial roles in enabling the production of next-generation electronic devices. Manufacturers in the wafer heaters market are continually innovating to enhance the performance and reliability of their products, ensuring they meet the stringent demands of modern semiconductor fabrication. This ongoing innovation is essential for maintaining competitiveness in a market that is both dynamic and highly technical. As such, the Global Wafer Heaters Market remains a vital component of the broader semiconductor industry, supporting the development of cutting-edge technologies that power our digital world.

PVD & CVD, Etching, Others in the Global Wafer Heaters Market:

The Global Wafer Heaters Market finds extensive usage in various semiconductor manufacturing processes, including Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), etching, and other specialized applications. In PVD processes, wafer heaters are crucial for maintaining the precise temperatures needed to deposit thin films of material onto semiconductor wafers. These films are essential for creating the intricate layers that form integrated circuits and other semiconductor devices. The uniform heat distribution provided by wafer heaters ensures that the deposited films have consistent thickness and quality, which is vital for the performance and reliability of the final products. Similarly, in CVD processes, wafer heaters play a critical role in facilitating the chemical reactions that deposit material onto the wafer surface. The ability to maintain stable and uniform temperatures is essential for achieving the desired film properties and ensuring the efficiency of the deposition process. In etching applications, wafer heaters are used to control the temperature of the wafer during the removal of material, a process that requires precise temperature management to achieve the desired etch profiles and minimize defects. Beyond these core applications, wafer heaters are also used in other specialized processes within the semiconductor industry, such as annealing and oxidation. In annealing, wafer heaters help to repair damage to the crystal structure of the wafer caused by previous processing steps, improving the electrical properties of the semiconductor devices. In oxidation, wafer heaters facilitate the growth of a thin oxide layer on the wafer surface, a critical step in the fabrication of many semiconductor devices. The versatility and precision of wafer heaters make them indispensable tools in the semiconductor manufacturing process, enabling the production of high-performance electronic components that power a wide range of applications. As the demand for semiconductors continues to grow, driven by advancements in technology and the proliferation of connected devices, the Global Wafer Heaters Market is expected to expand, supporting the development of innovative solutions that meet the evolving needs of the industry.

Global Wafer Heaters Market Outlook:

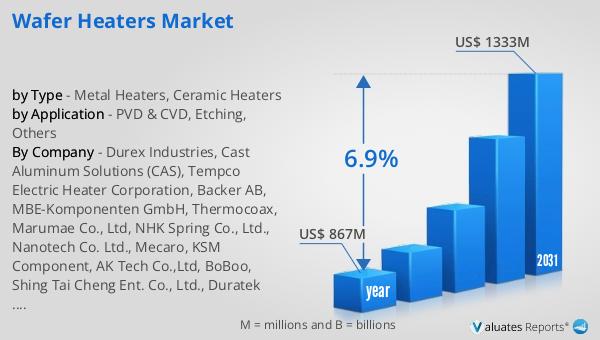

The worldwide market for wafer heaters was valued at $867 million in 2024 and is anticipated to grow to $1,333 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.9% over the forecast period. This growth underscores the increasing demand for wafer heaters as essential components in semiconductor manufacturing. Within this market, ceramic wafer heaters, particularly discs, are dominated by key players such as Sumitomo Electric, Kyocera, NGK Insulators, Mico Ceramics, BACH Resistor Ceramics, Semixicon, and CoorsTek. These top five companies collectively hold more than 68% of the market share, highlighting their significant influence and leadership in the industry. Ceramic heaters, in particular, are more widely utilized, accounting for approximately 65% of the application share. This preference for ceramic heaters is driven by their superior thermal properties, which make them ideal for high-precision applications in semiconductor manufacturing. As the semiconductor industry continues to advance, the demand for efficient and reliable wafer heaters is expected to rise, further propelling the growth of the Global Wafer Heaters Market. The ongoing innovation and development within this market are crucial for supporting the production of next-generation electronic devices that are integral to modern technology.

| Report Metric | Details |

| Report Name | Wafer Heaters Market |

| Accounted market size in year | US$ 867 million |

| Forecasted market size in 2031 | US$ 1333 million |

| CAGR | 6.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Durex Industries, Cast Aluminum Solutions (CAS), Tempco Electric Heater Corporation, Backer AB, MBE-Komponenten GmbH, Thermocoax, Marumae Co., Ltd, NHK Spring Co., Ltd., Nanotech Co. Ltd., Mecaro, KSM Component, AK Tech Co.,Ltd, BoBoo, Shing Tai Cheng Ent. Co., Ltd., Duratek Technology Co., Ltd., Sprint Precision Technologies Co., Ltd, Zhejiang Longji Lier Semiconductor Technology, Sanyue Semiconductor Technology, KVTS, Tolerance, TTS Co., Ltd., NGK insulator, Sumitomo Electric, CoorsTek, AMAT, MiCo Ceramics, Semixicon LLC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |