What is Global Straight Seam Submerged Arc Welded Pipe Market?

The Global Straight Seam Submerged Arc Welded Pipe Market is a significant segment within the broader steel pipe industry, characterized by its specialized manufacturing process and diverse applications. These pipes are produced using a method known as submerged arc welding, which involves forming a straight seam along the length of the pipe. This technique is renowned for its efficiency and ability to produce pipes with high strength and durability. The market for these pipes is driven by their extensive use in various industries, including oil and gas, construction, and infrastructure development. The demand is particularly high in regions with booming industrial activities and infrastructural projects. These pipes are preferred for their ability to withstand high pressure and harsh environmental conditions, making them ideal for transporting oil, gas, and other fluids over long distances. Additionally, their application in structural and architectural projects further boosts their market demand. As industries continue to expand and infrastructure projects proliferate globally, the market for straight seam submerged arc welded pipes is expected to grow, driven by technological advancements and the need for reliable and efficient piping solutions.

JCO Process, UOE Process, Others in the Global Straight Seam Submerged Arc Welded Pipe Market:

The manufacturing processes for straight seam submerged arc welded pipes, namely the JCO, UOE, and other methods, play a crucial role in determining the quality and application of the final product. The JCO process is a popular method named after the sequential steps of forming the pipe: J-ing, C-ing, and O-ing. In this process, a steel plate is first pressed into a J shape, then further into a C shape, and finally into an O shape, forming a circular pipe. This method is known for its precision and ability to produce pipes with uniform thickness and diameter, making it suitable for high-pressure applications. The UOE process, on the other hand, involves three main stages: U-ing, O-ing, and Expanding. Initially, the steel plate is bent into a U shape, then into an O shape, and finally expanded to achieve the desired diameter and roundness. This process is highly efficient and is often used for producing large-diameter pipes required in the oil and gas industry. The expansion step ensures that the pipe has a uniform diameter and improved mechanical properties, making it ideal for transporting fluids over long distances. Other methods of manufacturing straight seam submerged arc welded pipes include the spiral welding process, where the steel strip is helically wound and welded along the seam. This method is particularly advantageous for producing pipes with varying diameters and lengths, offering flexibility in meeting specific project requirements. Each of these processes has its unique advantages and is chosen based on the specific needs of the application, such as the required pipe diameter, thickness, and mechanical properties. The choice of process also impacts the cost and efficiency of production, influencing the overall market dynamics. As technology advances, these manufacturing processes continue to evolve, offering improved efficiency, precision, and cost-effectiveness, thereby driving the growth of the global straight seam submerged arc welded pipe market.

Oil and Gas, Architecture, Others in the Global Straight Seam Submerged Arc Welded Pipe Market:

The Global Straight Seam Submerged Arc Welded Pipe Market finds extensive usage across various sectors, with the oil and gas industry being one of the primary consumers. In this sector, these pipes are crucial for the transportation of oil, gas, and other fluids over long distances. Their ability to withstand high pressure and harsh environmental conditions makes them ideal for use in pipelines that traverse challenging terrains and climates. The durability and strength of these pipes ensure the safe and efficient transport of resources, minimizing the risk of leaks and environmental hazards. In the architectural sector, straight seam submerged arc welded pipes are used in the construction of buildings, bridges, and other infrastructure projects. Their structural integrity and ability to support heavy loads make them suitable for use in frameworks and support structures. These pipes are also used in the construction of high-rise buildings, where their strength and stability are crucial for ensuring the safety and longevity of the structure. Additionally, these pipes are used in various other industries, including water supply and sewage systems, where their corrosion resistance and durability are essential for maintaining the integrity of the pipelines. The versatility and reliability of straight seam submerged arc welded pipes make them a preferred choice for a wide range of applications, driving their demand in the global market. As industries continue to expand and infrastructure projects increase, the usage of these pipes is expected to grow, further boosting the market.

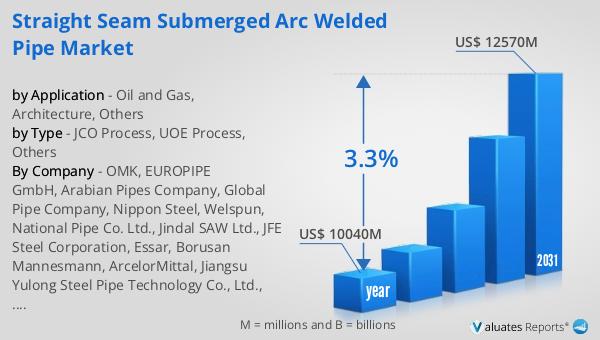

Global Straight Seam Submerged Arc Welded Pipe Market Outlook:

The global market for Straight Seam Submerged Arc Welded Pipe was valued at approximately $10.04 billion in 2024. It is anticipated to expand to a revised size of around $12.57 billion by 2031, reflecting a compound annual growth rate (CAGR) of 3.3% over the forecast period. This growth trajectory indicates a steady increase in demand for these pipes, driven by their extensive application across various industries. The market's expansion is fueled by the rising need for durable and efficient piping solutions in sectors such as oil and gas, construction, and infrastructure development. The projected growth rate underscores the importance of these pipes in supporting industrial activities and infrastructural projects worldwide. As industries continue to evolve and new projects emerge, the demand for straight seam submerged arc welded pipes is expected to rise, contributing to the market's overall growth. The increasing focus on technological advancements and the development of innovative manufacturing processes further enhance the market's potential, offering opportunities for manufacturers and stakeholders to capitalize on the growing demand. This positive market outlook reflects the critical role that straight seam submerged arc welded pipes play in various applications, ensuring their continued relevance and importance in the global market.

| Report Metric | Details |

| Report Name | Straight Seam Submerged Arc Welded Pipe Market |

| Accounted market size in year | US$ 10040 million |

| Forecasted market size in 2031 | US$ 12570 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | OMK, EUROPIPE GmbH, Arabian Pipes Company, Global Pipe Company, Nippon Steel, Welspun, National Pipe Co. Ltd., Jindal SAW Ltd., JFE Steel Corporation, Essar, Borusan Mannesmann, ArcelorMittal, Jiangsu Yulong Steel Pipe Technology Co., Ltd., ChelPipe Group, Panyu Chu Kong Steel Pipe, SEVERSTAL, JSW Steel Ltd., Attieh Steel Ltd, TMK Group, Cangzhou Steel Pipe Group (CSPG) Co., Ltd., Baoji Petroleum Steel Pipe, Zhejiang Kingland & Pipeline Technol-ogies Co.,Ltd, Shengli Oil & Gas Pipe |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |