What is Global High-Efficiency Particulate Air (HEPA) Filter Membrane Market?

The Global High-Efficiency Particulate Air (HEPA) Filter Membrane Market is a crucial segment within the broader air filtration industry, focusing on the development and distribution of advanced filtration solutions designed to capture microscopic particles. These filters are renowned for their ability to trap at least 99.97% of airborne particles that are 0.3 microns in diameter, making them essential in environments where air quality is paramount. The market encompasses a variety of applications, including residential, commercial, and industrial settings, where maintaining clean air is critical for health and operational efficiency. The demand for HEPA filter membranes is driven by increasing awareness of air pollution's health impacts, stringent regulatory standards, and the growing need for contamination control in various sectors. As industries and consumers alike prioritize air quality, the market for HEPA filter membranes continues to expand, offering innovative solutions that cater to diverse needs. This market is characterized by technological advancements, competitive dynamics, and a focus on sustainability, as manufacturers strive to develop more efficient and environmentally friendly products. The global reach of this market underscores its significance in promoting healthier living and working environments across different regions.

PTFE Membrane, Microglass Membrane in the Global High-Efficiency Particulate Air (HEPA) Filter Membrane Market:

Polytetrafluoroethylene (PTFE) membranes and microglass membranes are two prominent types of materials used in the Global High-Efficiency Particulate Air (HEPA) Filter Membrane Market. PTFE membranes are highly valued for their exceptional chemical resistance, thermal stability, and non-stick properties, making them ideal for a wide range of filtration applications. These membranes are particularly effective in environments where chemical exposure and high temperatures are prevalent, such as in industrial settings or laboratories. PTFE's unique properties allow it to maintain its integrity and performance even under harsh conditions, ensuring reliable filtration over extended periods. This durability and efficiency make PTFE membranes a preferred choice for industries that require stringent air quality control, such as pharmaceuticals, biotechnology, and electronics manufacturing. On the other hand, microglass membranes are composed of fine glass fibers that are intricately woven to create a dense and effective filtration medium. These membranes are known for their high dust-holding capacity and ability to capture submicron particles, making them suitable for applications where particulate matter needs to be controlled with precision. Microglass membranes are often used in environments where air purity is critical, such as cleanrooms, hospitals, and food processing facilities. The choice between PTFE and microglass membranes often depends on the specific requirements of the application, including factors such as temperature, chemical exposure, and the nature of the particles to be filtered. Both types of membranes play a vital role in the HEPA filter market, offering distinct advantages that cater to different industrial and commercial needs. As the demand for clean air solutions continues to rise, manufacturers are investing in research and development to enhance the performance and sustainability of these membranes, ensuring they meet the evolving needs of various sectors. The competition between PTFE and microglass membranes drives innovation, leading to the development of advanced filtration technologies that offer improved efficiency, longevity, and environmental compatibility. This ongoing evolution in membrane technology is a testament to the market's commitment to providing effective solutions for air quality management across diverse applications.

Commercial, Industrial in the Global High-Efficiency Particulate Air (HEPA) Filter Membrane Market:

The usage of Global High-Efficiency Particulate Air (HEPA) Filter Membranes in commercial and industrial areas is extensive and varied, reflecting the critical need for effective air filtration in these environments. In commercial settings, HEPA filters are commonly used in office buildings, shopping malls, and healthcare facilities to ensure a clean and healthy indoor environment for occupants. These filters help reduce the concentration of airborne pollutants, allergens, and pathogens, contributing to improved indoor air quality and occupant well-being. In healthcare facilities, such as hospitals and clinics, HEPA filters are essential for maintaining sterile environments, preventing the spread of infections, and protecting patients with compromised immune systems. The ability of HEPA filters to capture microscopic particles makes them indispensable in these settings, where air quality can directly impact patient outcomes. In industrial applications, HEPA filter membranes are used in manufacturing plants, laboratories, and cleanrooms to control airborne contaminants that could affect product quality and safety. Industries such as pharmaceuticals, biotechnology, and electronics rely on HEPA filters to maintain stringent air quality standards, ensuring that their products are free from contamination. In manufacturing environments, HEPA filters help protect workers from exposure to hazardous substances, such as dust, fumes, and chemical vapors, promoting a safer workplace. The versatility of HEPA filter membranes allows them to be integrated into various HVAC systems, air purifiers, and specialized filtration units, providing tailored solutions for different industrial and commercial needs. As businesses and industries continue to prioritize air quality, the demand for HEPA filter membranes is expected to grow, driven by regulatory requirements, health concerns, and the pursuit of operational efficiency. The ongoing development of advanced filtration technologies further enhances the capabilities of HEPA filters, enabling them to meet the evolving challenges of air quality management in commercial and industrial settings.

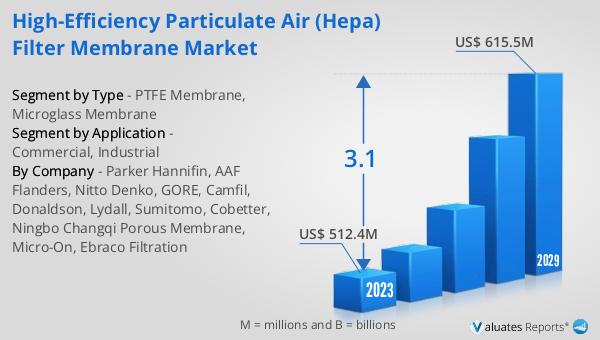

Global High-Efficiency Particulate Air (HEPA) Filter Membrane Market Outlook:

The global market for High-Efficiency Particulate Air (HEPA) Filter Membranes was valued at approximately $527 million in 2024, with projections indicating it could reach around $650 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.1% over the forecast period. The market is dominated by the top five companies, which collectively hold about 60% of the market share. North America emerges as the largest regional market, accounting for roughly 37% of the global share, followed by Europe and the Asia Pacific, which hold approximately 34% and 17%, respectively. Among the various product types, PTFE membranes stand out as the largest segment, commanding over 80% of the market share. This dominance is attributed to PTFE's superior properties, such as chemical resistance and thermal stability, which make it highly suitable for a wide range of applications. The market dynamics are shaped by factors such as technological advancements, regulatory standards, and the increasing emphasis on air quality across different sectors. As the demand for effective air filtration solutions continues to rise, the HEPA filter membrane market is poised for sustained growth, driven by innovation and the need for cleaner, healthier environments.

| Report Metric | Details |

| Report Name | High-Efficiency Particulate Air (HEPA) Filter Membrane Market |

| Accounted market size in year | US$ 527 million |

| Forecasted market size in 2031 | US$ 650 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Parker Hannifin, AAF Flanders, Nitto Denko, GORE, Camfil, Donaldson, Lydall, Sumitomo, Cobetter, Ningbo Changqi Porous Membrane, Micro-On, Ebraco Filtration |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |