What is Global Glass Fiber Reinforced Plastic Rebar Market?

The Global Glass Fiber Reinforced Plastic (GFRP) Rebar Market is a specialized segment within the construction materials industry, focusing on the production and application of composite materials that combine glass fibers with plastic resins to create a strong, lightweight, and corrosion-resistant alternative to traditional steel rebar. This market is driven by the increasing demand for durable and sustainable construction materials that can withstand harsh environmental conditions and reduce maintenance costs over time. GFRP rebar is particularly valued for its high tensile strength, low weight, and resistance to chemical and moisture-induced degradation, making it an ideal choice for infrastructure projects in coastal and industrial areas. The market encompasses a wide range of applications, including bridge and dam construction, offshore oil and gas engineering, wind power towers, and nuclear power plants, among others. As the construction industry continues to evolve towards more sustainable and resilient building practices, the GFRP rebar market is poised for significant growth, offering innovative solutions to meet the challenges of modern infrastructure development. The market's expansion is further supported by advancements in manufacturing technologies and increased awareness of the long-term benefits of using composite materials in construction.

Diameter Below 10mm, Diameter 10 to 20mm (Including 10mm), Diameter Above 20mm (Including 20mm) in the Global Glass Fiber Reinforced Plastic Rebar Market:

In the Global Glass Fiber Reinforced Plastic Rebar Market, the diameter of the rebar plays a crucial role in determining its application and performance characteristics. Rebar with a diameter below 10mm is typically used in applications where flexibility and ease of handling are paramount. These smaller diameter rebars are ideal for reinforcing structures that require intricate designs or where space constraints limit the use of larger materials. They are often employed in residential construction, small-scale infrastructure projects, and in areas where lightweight reinforcement is necessary to reduce the overall load on the structure. The flexibility of these rebars allows for easy bending and shaping, making them suitable for complex architectural designs and detailed construction work. On the other hand, rebar with a diameter ranging from 10mm to 20mm, including 10mm, is more commonly used in medium to large-scale construction projects. This range of diameters offers a balance between strength and flexibility, making it suitable for a wide variety of applications, including commercial buildings, bridges, and highways. The increased diameter provides greater tensile strength, allowing these rebars to support heavier loads and withstand greater stress, which is essential for ensuring the structural integrity of larger constructions. Additionally, the use of GFRP rebar in this diameter range is advantageous in environments where corrosion resistance is critical, such as in marine or chemically aggressive settings. For projects requiring even greater strength and load-bearing capacity, rebar with a diameter above 20mm, including 20mm, is utilized. These larger diameter rebars are designed to provide maximum reinforcement for heavy-duty applications, such as in the construction of dams, high-rise buildings, and industrial facilities. The robust nature of these rebars ensures that they can support substantial weight and resist deformation under extreme conditions. Moreover, the use of GFRP rebar in this category offers significant advantages in terms of longevity and durability, as it is impervious to rust and corrosion, which are common issues with traditional steel rebar. This makes them particularly suitable for use in environments where exposure to moisture, salt, or chemicals is prevalent. Overall, the choice of rebar diameter in the Global Glass Fiber Reinforced Plastic Rebar Market is dictated by the specific requirements of the construction project, with each size offering distinct benefits in terms of strength, flexibility, and resistance to environmental factors. As the demand for sustainable and resilient construction materials continues to grow, the market for GFRP rebar across all diameter categories is expected to expand, driven by the need for innovative solutions that address the challenges of modern infrastructure development.

Bridge and Dam Building, Offshore Oil and Gas Engineering, Wind Power Tower, Nuclear Power Plant, Others in the Global Glass Fiber Reinforced Plastic Rebar Market:

The Global Glass Fiber Reinforced Plastic Rebar Market finds extensive usage across various sectors, each with unique requirements and challenges. In bridge and dam building, GFRP rebar is highly valued for its corrosion resistance and high tensile strength. These structures are often exposed to harsh environmental conditions, including moisture, salt, and temperature fluctuations, which can lead to the deterioration of traditional steel rebar. By using GFRP rebar, engineers can enhance the longevity and durability of bridges and dams, reducing maintenance costs and ensuring the safety and reliability of these critical infrastructures. The lightweight nature of GFRP rebar also facilitates easier transportation and installation, further contributing to its appeal in large-scale construction projects. In offshore oil and gas engineering, GFRP rebar is used to reinforce structures that are constantly exposed to corrosive marine environments. The non-corrosive properties of GFRP rebar make it an ideal choice for constructing platforms, pipelines, and other offshore facilities, where the integrity of the structure is paramount to preventing environmental disasters and ensuring the safety of personnel. Additionally, the high strength-to-weight ratio of GFRP rebar allows for the design of more efficient and cost-effective structures, which is a significant advantage in the highly competitive oil and gas industry. Wind power towers also benefit from the use of GFRP rebar, as these structures require materials that can withstand dynamic loads and harsh weather conditions. The flexibility and strength of GFRP rebar make it suitable for reinforcing the foundations and towers of wind turbines, ensuring their stability and performance over time. Furthermore, the use of GFRP rebar in wind power projects aligns with the industry's focus on sustainability and reducing the environmental impact of energy production. In nuclear power plants, the safety and reliability of construction materials are of utmost importance. GFRP rebar is used to reinforce containment structures, cooling towers, and other critical components, providing the necessary strength and resistance to radiation and chemical exposure. The non-conductive nature of GFRP rebar also offers additional safety benefits, reducing the risk of electrical hazards in sensitive areas. Beyond these specific applications, GFRP rebar is also used in a variety of other construction projects, including residential and commercial buildings, tunnels, and retaining walls. Its versatility and performance characteristics make it a preferred choice for engineers and architects seeking innovative solutions to meet the demands of modern construction. As the construction industry continues to evolve, the Global Glass Fiber Reinforced Plastic Rebar Market is expected to play an increasingly important role in shaping the future of infrastructure development.

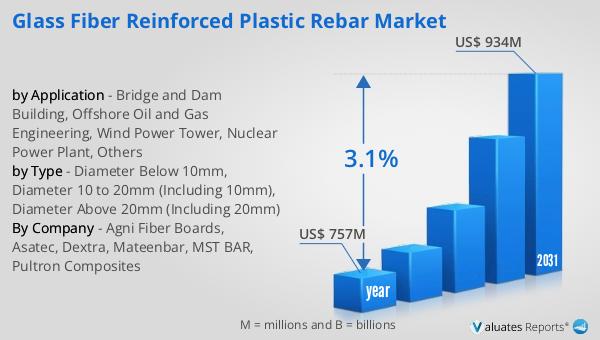

Global Glass Fiber Reinforced Plastic Rebar Market Outlook:

In 2024, the Global Glass Fiber Reinforced Plastic Rebar Market was valued at approximately $757 million, reflecting its significant role in the construction industry. This market is anticipated to grow steadily, reaching an estimated value of $934 million by 2031, with a compound annual growth rate (CAGR) of 3.1% over the forecast period. This growth trajectory underscores the increasing demand for durable and sustainable construction materials that can withstand harsh environmental conditions and reduce maintenance costs. The market is characterized by a competitive landscape, with the top five players collectively holding a market share exceeding 33%. This concentration of market power highlights the importance of innovation and strategic partnerships in maintaining a competitive edge. As the construction industry continues to prioritize sustainability and resilience, the demand for GFRP rebar is expected to rise, driven by its superior performance characteristics and long-term benefits. The market's expansion is further supported by advancements in manufacturing technologies and increased awareness of the advantages of using composite materials in construction. As a result, the Global Glass Fiber Reinforced Plastic Rebar Market is poised for significant growth, offering innovative solutions to meet the challenges of modern infrastructure development.

| Report Metric | Details |

| Report Name | Glass Fiber Reinforced Plastic Rebar Market |

| Accounted market size in year | US$ 757 million |

| Forecasted market size in 2031 | US$ 934 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Agni Fiber Boards, Asatec, Dextra, Mateenbar, MST BAR, Pultron Composites |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |