What is Global Drag Reducing Agent for Gas Transportation Market?

The Global Drag Reducing Agent (DRA) for Gas Transportation Market is a specialized segment within the broader energy and transportation sectors. DRAs are chemical compounds used to reduce frictional pressure loss in pipelines, thereby enhancing the flow efficiency of gas transportation systems. This market is crucial for optimizing the performance of gas pipelines, which are essential for transporting natural gas and other gaseous fuels over long distances. By minimizing turbulence and drag within the pipeline, DRAs enable a more efficient and cost-effective transportation process. This not only helps in reducing energy consumption but also in lowering operational costs. The demand for DRAs is driven by the increasing need for energy efficiency and the growing global energy demand. As countries strive to meet their energy needs while minimizing environmental impact, the role of DRAs becomes increasingly significant. The market is characterized by continuous innovation and development of new formulations to meet the specific needs of different pipeline systems and environmental conditions. Overall, the Global Drag Reducing Agent for Gas Transportation Market plays a vital role in ensuring the efficient and sustainable transportation of gas resources worldwide.

High Viscosity Glue, Low Viscosity Glue in the Global Drag Reducing Agent for Gas Transportation Market:

High Viscosity Glue and Low Viscosity Glue are two types of drag reducing agents used in the Global Drag Reducing Agent for Gas Transportation Market. High Viscosity Glue is designed to work in environments where the gas flow is turbulent and the pipeline conditions are challenging. This type of glue is particularly effective in reducing drag in pipelines with high flow rates and pressure. It works by forming a thin film on the pipeline walls, which reduces friction and allows the gas to flow more smoothly. This results in increased flow capacity and reduced energy consumption, making it an ideal choice for long-distance gas transportation. On the other hand, Low Viscosity Glue is used in situations where the gas flow is relatively stable and the pipeline conditions are less demanding. This type of glue is easier to apply and requires less maintenance, making it a cost-effective solution for pipelines with moderate flow rates. It works by reducing the surface tension of the gas, which minimizes turbulence and drag. Both types of glue are essential for optimizing the performance of gas transportation systems, and their usage depends on the specific requirements of the pipeline and the type of gas being transported. The choice between High Viscosity Glue and Low Viscosity Glue is determined by factors such as the pipeline's diameter, the gas's composition, and the environmental conditions. In some cases, a combination of both types of glue may be used to achieve the desired level of drag reduction. The development of new formulations and technologies in this field is ongoing, with researchers and manufacturers constantly seeking ways to improve the efficiency and effectiveness of these agents. As the demand for energy continues to grow, the importance of High Viscosity Glue and Low Viscosity Glue in the Global Drag Reducing Agent for Gas Transportation Market is expected to increase. These agents not only help in reducing operational costs but also contribute to the sustainability of gas transportation systems by minimizing energy consumption and environmental impact. In conclusion, High Viscosity Glue and Low Viscosity Glue are critical components of the Global Drag Reducing Agent for Gas Transportation Market, each serving a unique purpose in enhancing the efficiency and sustainability of gas transportation systems.

Natural Gas Liquid Transportation, Liquefied Petroleum Gas Transportation, Others in the Global Drag Reducing Agent for Gas Transportation Market:

The usage of Global Drag Reducing Agents (DRAs) in gas transportation is pivotal in various sectors, including Natural Gas Liquid (NGL) Transportation, Liquefied Petroleum Gas (LPG) Transportation, and other related areas. In the realm of Natural Gas Liquid Transportation, DRAs play a crucial role in optimizing the flow of NGLs through pipelines. These agents work by reducing the frictional resistance within the pipeline, allowing for a smoother and more efficient flow of the liquid gas. This not only enhances the capacity of the pipeline but also reduces the energy required for pumping, leading to significant cost savings. The use of DRAs in NGL transportation is particularly important in regions with extensive pipeline networks, where maximizing flow efficiency is essential for meeting energy demands. In Liquefied Petroleum Gas Transportation, DRAs are equally important. LPG, being a mixture of propane and butane, requires careful handling and transportation. DRAs help in maintaining the flow efficiency of LPG pipelines by minimizing turbulence and drag. This ensures that the LPG is transported safely and efficiently, reducing the risk of pressure build-up and potential pipeline failures. The use of DRAs in LPG transportation also contributes to the overall safety and reliability of the gas supply chain, which is critical for both domestic and industrial applications. Beyond NGL and LPG transportation, DRAs find applications in other areas of gas transportation as well. These include the transportation of various gaseous fuels and industrial gases, where maintaining flow efficiency is crucial for operational success. In these applications, DRAs help in reducing the operational costs and energy consumption associated with gas transportation, making them an essential component of modern pipeline systems. The versatility and effectiveness of DRAs in enhancing the flow efficiency of gas transportation systems make them indispensable in the energy sector. As the demand for energy continues to rise, the role of DRAs in ensuring the efficient and sustainable transportation of gas resources becomes increasingly important. In conclusion, the usage of Global Drag Reducing Agents in Natural Gas Liquid Transportation, Liquefied Petroleum Gas Transportation, and other areas is vital for optimizing the performance and sustainability of gas transportation systems. These agents not only enhance the flow efficiency of pipelines but also contribute to the overall safety and reliability of the gas supply chain.

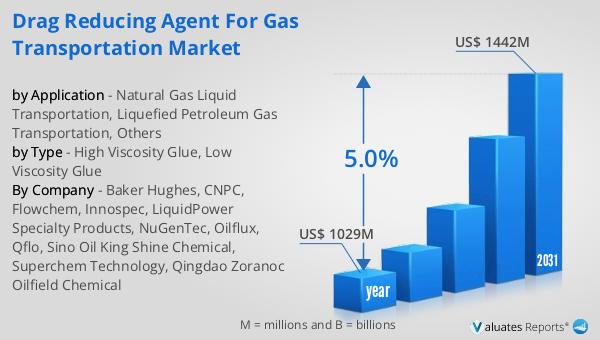

Global Drag Reducing Agent for Gas Transportation Market Outlook:

The global market for Drag Reducing Agents (DRAs) in gas transportation is experiencing significant growth. In 2024, the market was valued at approximately US$ 1029 million. This figure is projected to increase to around US$ 1442 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.0% over the forecast period. This growth is driven by the increasing demand for energy efficiency and the need to optimize the performance of gas transportation systems. DRAs play a crucial role in reducing frictional pressure loss in pipelines, thereby enhancing the flow efficiency of gas transportation. This not only helps in reducing energy consumption but also in lowering operational costs. The market is characterized by continuous innovation and development of new formulations to meet the specific needs of different pipeline systems and environmental conditions. As countries strive to meet their energy needs while minimizing environmental impact, the role of DRAs becomes increasingly significant. The market's growth is also supported by the expanding global energy demand and the need for sustainable transportation solutions. Overall, the global market for Drag Reducing Agents in gas transportation is poised for continued growth, driven by the increasing focus on energy efficiency and sustainability.

| Report Metric | Details |

| Report Name | Drag Reducing Agent for Gas Transportation Market |

| Accounted market size in year | US$ 1029 million |

| Forecasted market size in 2031 | US$ 1442 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Baker Hughes, CNPC, Flowchem, Innospec, LiquidPower Specialty Products, NuGenTec, Oilflux, Qflo, Sino Oil King Shine Chemical, Superchem Technology, Qingdao Zoranoc Oilfield Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |