What is Global Beryllium Copper Strip Market?

The Global Beryllium Copper Strip Market is a specialized segment within the broader metal industry, focusing on the production and distribution of beryllium copper strips. These strips are known for their unique combination of strength, conductivity, and resistance to corrosion, making them highly sought after in various industrial applications. Beryllium copper is an alloy that combines copper with beryllium, offering enhanced mechanical properties and thermal stability. This market is driven by the demand from sectors such as electronics, automotive, and aerospace, where the material's properties are crucial for performance and reliability. The market is characterized by technological advancements and innovations aimed at improving the quality and efficiency of beryllium copper strips. Manufacturers are continually exploring new applications and improving production processes to meet the evolving needs of end-users. The global reach of this market is facilitated by a network of suppliers and distributors who ensure the availability of these materials across different regions. As industries continue to seek materials that offer superior performance, the Global Beryllium Copper Strip Market is poised for sustained growth, driven by its critical role in modern manufacturing and technology.

Beryllium Content is 0.2% to 0.6%, Beryllium Content is 1.6% to 2.0%, Others in the Global Beryllium Copper Strip Market:

Beryllium copper strips are categorized based on their beryllium content, which significantly influences their properties and applications. Strips with a beryllium content ranging from 0.2% to 0.6% are typically used in applications where moderate strength and good conductivity are required. This range of beryllium content provides a balance between mechanical strength and electrical conductivity, making these strips suitable for use in connectors, switches, and other electrical components. The lower beryllium content ensures that the material remains ductile and easy to work with, which is essential for manufacturing processes that involve bending or forming the strips into specific shapes. On the other hand, beryllium copper strips with a beryllium content of 1.6% to 2.0% are known for their exceptional strength and hardness. These strips are often used in applications that demand high performance under stress, such as in aerospace components, precision instruments, and heavy-duty industrial machinery. The higher beryllium content enhances the alloy's ability to withstand wear and fatigue, making it ideal for environments where durability is paramount. Additionally, these strips offer excellent thermal conductivity, which is beneficial in applications that involve heat dissipation. Beyond these specific beryllium content ranges, there are other variations of beryllium copper strips that cater to niche applications. These may include customized alloys with specific properties tailored to meet the unique requirements of certain industries. For instance, some applications may require strips with enhanced corrosion resistance or specific magnetic properties, which can be achieved by adjusting the alloy composition. The versatility of beryllium copper strips, combined with their ability to be customized, makes them a valuable material in a wide range of industrial applications. Manufacturers in the Global Beryllium Copper Strip Market are continually innovating to develop new alloys and improve existing ones, ensuring that they can meet the diverse needs of their customers. This focus on innovation and customization is a key driver of growth in the market, as it allows manufacturers to offer solutions that are precisely aligned with the demands of different industries. As a result, the market for beryllium copper strips is characterized by a high degree of specialization, with manufacturers often working closely with their customers to develop materials that meet specific performance criteria. This collaborative approach not only enhances the quality and performance of the final products but also strengthens the relationships between manufacturers and their customers, fostering long-term partnerships that are beneficial for both parties.

Automotive, Consumer Electronics, Aerospace, Others in the Global Beryllium Copper Strip Market:

The Global Beryllium Copper Strip Market finds extensive usage across various industries, with significant applications in the automotive, consumer electronics, aerospace, and other sectors. In the automotive industry, beryllium copper strips are valued for their strength, conductivity, and resistance to wear and corrosion. These properties make them ideal for use in components such as connectors, switches, and sensors, which are critical for the performance and safety of modern vehicles. The ability of beryllium copper to withstand harsh environmental conditions and maintain its performance over time is particularly important in automotive applications, where reliability and durability are paramount. In the consumer electronics sector, beryllium copper strips are used in a wide range of devices, from smartphones and tablets to laptops and wearable technology. The material's excellent electrical conductivity and thermal stability make it ideal for use in connectors, sockets, and other components that require efficient transmission of electrical signals. Additionally, the miniaturization of electronic devices has increased the demand for materials that can deliver high performance in compact form factors, a requirement that beryllium copper strips are well-suited to meet. The aerospace industry also relies heavily on beryllium copper strips, particularly in applications that demand high strength and resistance to fatigue. Components such as landing gear, control systems, and structural parts benefit from the material's ability to withstand extreme conditions and maintain its integrity over long periods. The lightweight nature of beryllium copper, combined with its strength, makes it an attractive choice for aerospace applications where weight reduction is a critical factor. Beyond these primary industries, beryllium copper strips are used in a variety of other applications, including telecommunications, industrial machinery, and medical devices. In telecommunications, the material's conductivity and durability are essential for the performance of network infrastructure components. In industrial machinery, beryllium copper strips are used in parts that require high wear resistance and reliability, such as bearings and bushings. In the medical field, the biocompatibility and non-magnetic properties of beryllium copper make it suitable for use in surgical instruments and imaging equipment. The versatility of beryllium copper strips, combined with their unique properties, ensures their continued relevance across a wide range of industries. As technology continues to advance and industries seek materials that offer superior performance, the demand for beryllium copper strips is expected to remain strong, driven by their critical role in enabling innovation and enhancing the performance of modern products and systems.

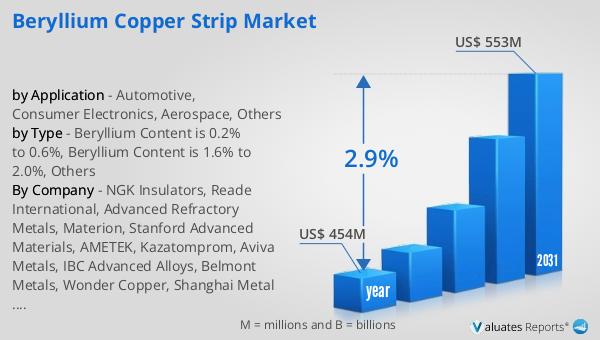

Global Beryllium Copper Strip Market Outlook:

In 2024, the global market for Beryllium Copper Strip was valued at approximately $454 million. Looking ahead, this market is anticipated to expand, reaching an estimated value of $553 million by the year 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 2.9% over the forecast period. The steady increase in market size underscores the rising demand for beryllium copper strips across various industries, driven by their unique properties and versatile applications. As industries continue to evolve and seek materials that offer enhanced performance, the role of beryllium copper strips becomes increasingly significant. The projected growth in market value highlights the ongoing importance of this material in sectors such as automotive, consumer electronics, and aerospace, where its strength, conductivity, and resistance to wear and corrosion are highly valued. The market's expansion is also indicative of the continuous innovation and development efforts by manufacturers to meet the evolving needs of their customers. As the global economy continues to recover and industrial activities gain momentum, the demand for beryllium copper strips is expected to remain robust, supporting the market's growth and contributing to its long-term sustainability.

| Report Metric | Details |

| Report Name | Beryllium Copper Strip Market |

| Accounted market size in year | US$ 454 million |

| Forecasted market size in 2031 | US$ 553 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NGK Insulators, Reade International, Advanced Refractory Metals, Materion, Stanford Advanced Materials, AMETEK, Kazatomprom, Aviva Metals, IBC Advanced Alloys, Belmont Metals, Wonder Copper, Shanghai Metal Corporation, Jinfeng Metal, Lanfeng Non-ferrous Metal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |