What is Global 3D Printing Materials and Equipment Market?

The Global 3D Printing Materials and Equipment Market is a rapidly evolving sector that encompasses a wide range of materials and technologies used in the additive manufacturing process. This market includes various types of materials such as plastics, metals, and ceramics, as well as the equipment necessary to transform these materials into three-dimensional objects. The technology behind 3D printing allows for the creation of complex structures with high precision, making it a valuable tool across numerous industries. The market is driven by the increasing demand for customized products, advancements in technology, and the growing adoption of 3D printing in various sectors such as automotive, healthcare, and aerospace. As industries continue to recognize the benefits of 3D printing, such as reduced material waste and the ability to produce intricate designs, the market for 3D printing materials and equipment is expected to expand significantly. This growth is further supported by ongoing research and development efforts aimed at improving the quality and performance of 3D printing materials and equipment. Overall, the Global 3D Printing Materials and Equipment Market represents a dynamic and promising field with the potential to revolutionize manufacturing processes across the globe.

Ceramics, Plastics, Metals, Fused Deposition Modeling, Selective Laser Sintering, Stereolithography, Colorjet in the Global 3D Printing Materials and Equipment Market:

In the realm of 3D printing, materials such as ceramics, plastics, and metals play a crucial role in determining the quality and functionality of the final product. Ceramics are known for their high heat resistance and strength, making them ideal for applications that require durability and thermal stability. They are often used in industries such as aerospace and medical for producing components that can withstand extreme conditions. Plastics, on the other hand, are the most commonly used materials in 3D printing due to their versatility and cost-effectiveness. They are available in various forms, including ABS, PLA, and nylon, each offering unique properties suitable for different applications. Metals like titanium, aluminum, and stainless steel are also widely used in 3D printing, particularly in industries that require strong and lightweight components, such as automotive and aerospace. These materials allow for the production of parts with high structural integrity and precision. The technology behind 3D printing is equally diverse, with several methods available to suit different needs. Fused Deposition Modeling (FDM) is one of the most popular techniques, known for its simplicity and affordability. It involves the extrusion of thermoplastic filaments through a heated nozzle, layer by layer, to create a 3D object. This method is widely used for prototyping and producing functional parts. Selective Laser Sintering (SLS) is another technique that uses a laser to fuse powdered material, such as nylon or metal, into solid structures. SLS is favored for its ability to produce complex geometries and high-strength parts without the need for support structures. Stereolithography (SLA) is a method that uses a laser to cure liquid resin into solid layers, offering high precision and smooth surface finishes. It is commonly used in industries that require detailed and intricate designs, such as jewelry and dental. ColorJet printing is a unique technology that allows for full-color 3D printing by binding colored powder with a liquid binder. This method is particularly useful for creating realistic prototypes and models with vibrant colors and intricate details. Each of these technologies has its own set of advantages and limitations, making them suitable for different applications and industries. As the Global 3D Printing Materials and Equipment Market continues to grow, advancements in these technologies are expected to enhance their capabilities and expand their applications. The ongoing development of new materials and printing techniques is likely to further drive the adoption of 3D printing across various sectors, offering new possibilities for innovation and efficiency.

Electronics & Consumer Products, Automotive, Medical, Industrial, Education, Aerospace in the Global 3D Printing Materials and Equipment Market:

The Global 3D Printing Materials and Equipment Market has found extensive applications across various industries, each leveraging the unique capabilities of 3D printing to enhance their operations. In the electronics and consumer products sector, 3D printing is used to create prototypes and functional components with intricate designs and precise specifications. This technology allows for rapid prototyping, enabling companies to test and refine their products quickly and cost-effectively. Additionally, 3D printing enables the production of customized consumer products, catering to the growing demand for personalized items. In the automotive industry, 3D printing is revolutionizing the way vehicles are designed and manufactured. It allows for the production of lightweight and complex components, reducing the overall weight of vehicles and improving fuel efficiency. Automotive manufacturers use 3D printing to create prototypes, tooling, and even end-use parts, streamlining the production process and reducing lead times. The ability to produce parts on-demand also reduces inventory costs and enhances supply chain efficiency. The medical field has also embraced 3D printing for its ability to produce customized implants, prosthetics, and surgical instruments. This technology allows for the creation of patient-specific solutions, improving the fit and functionality of medical devices. 3D printing is also used in the production of anatomical models for surgical planning and training, enhancing the precision and effectiveness of medical procedures. In the industrial sector, 3D printing is used for producing complex machinery components and tooling. It enables manufacturers to create parts with intricate geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This capability is particularly valuable in industries such as aerospace, where precision and performance are critical. 3D printing allows for the production of lightweight and high-strength components, improving the efficiency and performance of aircraft. The education sector is also benefiting from 3D printing, as it provides students with hands-on experience in design and manufacturing. Educational institutions use 3D printing to teach students about engineering, design, and technology, preparing them for careers in various industries. This technology fosters creativity and innovation, encouraging students to explore new ideas and solutions. In the aerospace industry, 3D printing is used to produce lightweight and high-performance components for aircraft and spacecraft. This technology allows for the creation of complex geometries and structures that enhance the performance and efficiency of aerospace vehicles. 3D printing also enables the production of parts on-demand, reducing lead times and inventory costs. As the aerospace industry continues to push the boundaries of innovation, 3D printing is expected to play a crucial role in the development of next-generation aircraft and spacecraft.

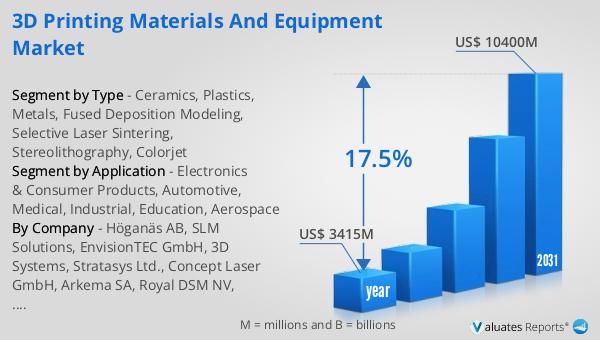

Global 3D Printing Materials and Equipment Market Outlook:

The global market for 3D Printing Materials and Equipment was valued at $3,415 million in 2024, and it is anticipated to grow significantly over the coming years. By 2031, the market is projected to reach an impressive size of $10,400 million, reflecting a robust compound annual growth rate (CAGR) of 17.5% during the forecast period. This substantial growth is indicative of the increasing adoption of 3D printing technologies across various industries, driven by the demand for customized and efficient manufacturing solutions. The market's expansion is supported by advancements in 3D printing materials and equipment, which are enhancing the capabilities and applications of this technology. As industries continue to recognize the benefits of 3D printing, such as reduced material waste, improved design flexibility, and faster production times, the demand for 3D printing materials and equipment is expected to rise. This growth trajectory highlights the transformative potential of 3D printing in revolutionizing traditional manufacturing processes and driving innovation across multiple sectors. The increasing investment in research and development, coupled with the growing awareness of the advantages of 3D printing, is likely to further propel the market's growth in the coming years.

| Report Metric | Details |

| Report Name | 3D Printing Materials and Equipment Market |

| Accounted market size in year | US$ 3415 million |

| Forecasted market size in 2031 | US$ 10400 million |

| CAGR | 17.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Höganäs AB, SLM Solutions, EnvisionTEC GmbH, 3D Systems, Stratasys Ltd., Concept Laser GmbH, Arkema SA, Royal DSM NV, Solidscape, Arcam AB, EOS GmbH, ExOne, voxeljet AG, Optomec, LPW Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |